Splicing method of honeycomb type underground engineering structure system

A kind of underground engineering, honeycomb technology, applied in the direction of underwater structures, water conservancy engineering, infrastructure engineering, etc., can solve the problems of underground engineering volume, space waste, poor force, etc., to achieve enhanced stability and firmness, and improve connection strength and airtightness, the effect of increasing the length space area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

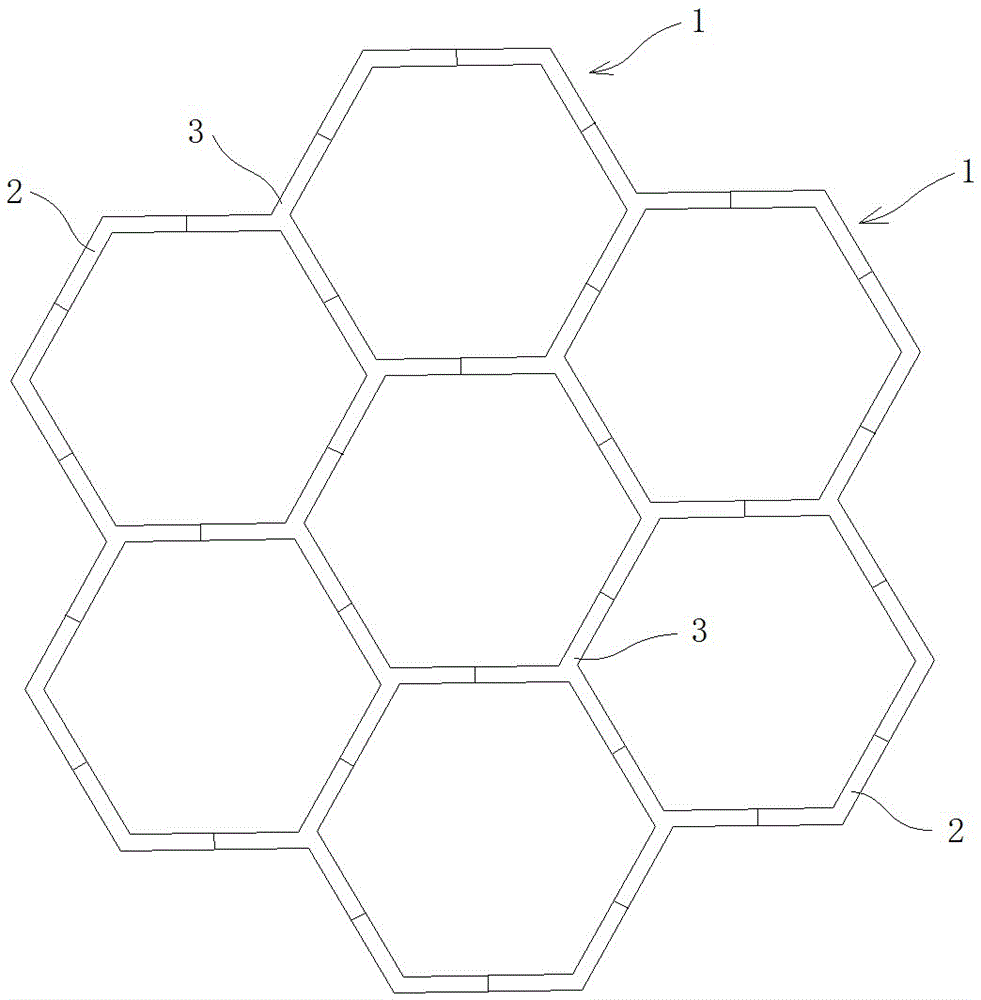

[0031] Embodiment 1: as Figure 1-5 As shown, this embodiment specifically relates to a method for assembling a honeycomb underground engineering structure system. The honeycomb underground engineering structure system is specifically composed of several regular hexagonal pipe bodies 1 arranged in parallel. The number of hexagonal pipe bodies 1 can be 2, 3...7, or even more. By selecting different numbers of regular hexagonal pipe bodies 1, they can be assembled and combined into different honeycomb underground engineering structure systems, such as the upper and lower overlapping , side-by-side, center-surrounding, etc., that is to say, by adopting a regular hexagonal cross-section for the pipe body, the structural stability of the honeycomb structure system can be enhanced, and a variety of different structures can be arranged according to actual engineering needs. In addition, the regular hexagonal tube body 1 can facilitate the assembly and combination between adjacent tub...

Embodiment 2

[0043] Embodiment 2: as Image 6 As shown, on the basis of the honeycomb underground engineering structure system described in Embodiment 1, this embodiment further proposes the practical application of the assembled honeycomb underground engineering structure system, that is, the interval tunnel and the underground comprehensive utility corridor Centralized design is carried out in the honeycomb underground engineering structure system to intensively utilize the underground space in the city.

[0044] like Image 6 As shown, the regular hexagonal pipe body 1 can be an underground comprehensive utility gallery 1a or a section tunnel 1b. That is to say, the honeycomb underground engineering structure system can be composed of such Image 6 The shown underground comprehensive utility gallery 1a and section tunnel 1b are formed by a combination, and the quantity collocation of underground comprehensive utility gallery 1a and section tunnel 1b can be determined according to actu...

Embodiment 3

[0047] Embodiment 3: as Figure 7 As shown, this embodiment specifically relates to a honeycomb underground engineering structure system, which is different from the honeycomb underground engineering structure system in Embodiment 2 in that: the honeycomb underground engineering structure system in this embodiment is all composed of intervals Tunnel 1b combined.

[0048] By combining several interval tunnels 1b to form a honeycomb underground engineering structure system, the intensive utilization rate of interval tunnels in the underground space can be improved, especially in the case of multiple parallel tunnels, the advantages of this honeycomb underground engineering structure system It is more obvious, because in the past, when multiple circular tunnels ran parallel, it was necessary to consider the reserved safety distance between each other, but in this embodiment, after setting the cross-section of the section tunnel 1b as a regular hexagon, they can be combined to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com