Underwater modular oil-gas production platform and working method thereof

A production platform and modular technology, which is applied in the fields of earthwork drilling, underwater structures, infrastructure engineering, etc., can solve the problems of large demand for flexible jumper pipes, long maintenance time, easy failure, etc., and achieve the reduction of installation technology Difficulty, load-bearing capacity requirements are reduced, and the effect of the automation process is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be further described below with reference to the accompanying drawings.

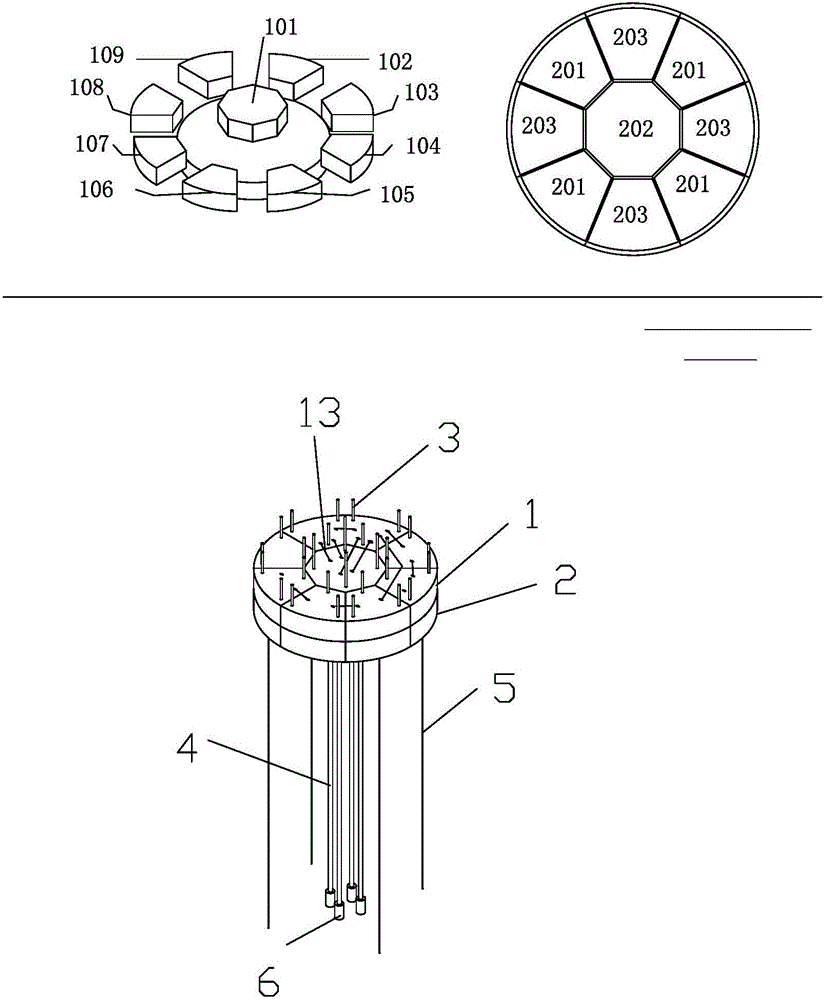

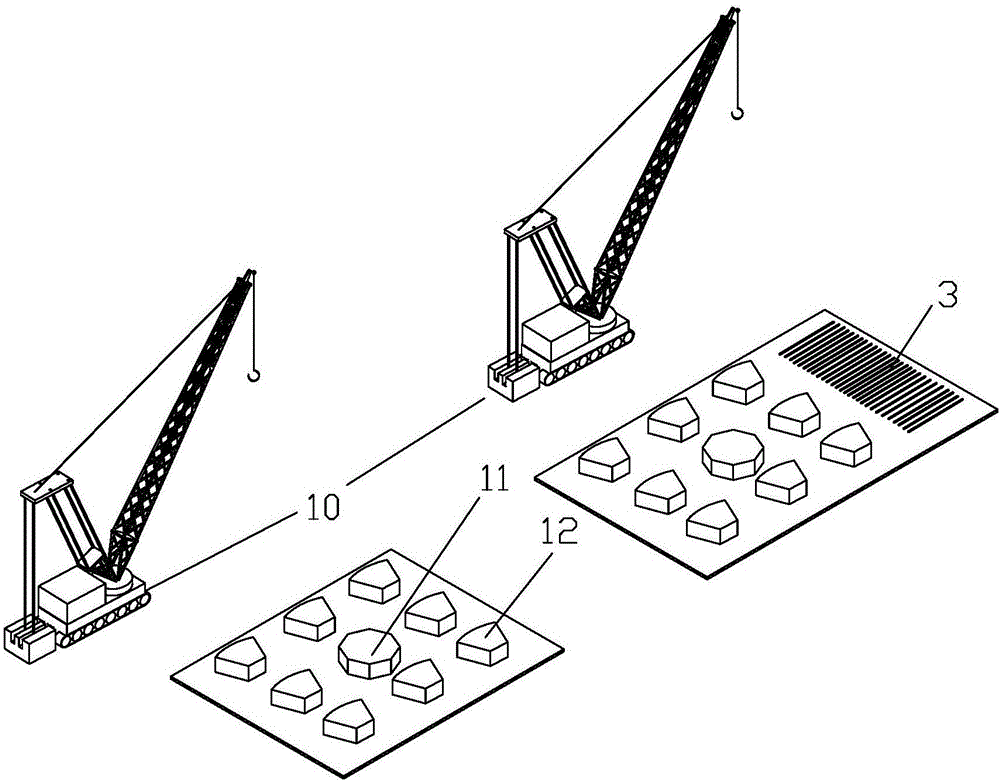

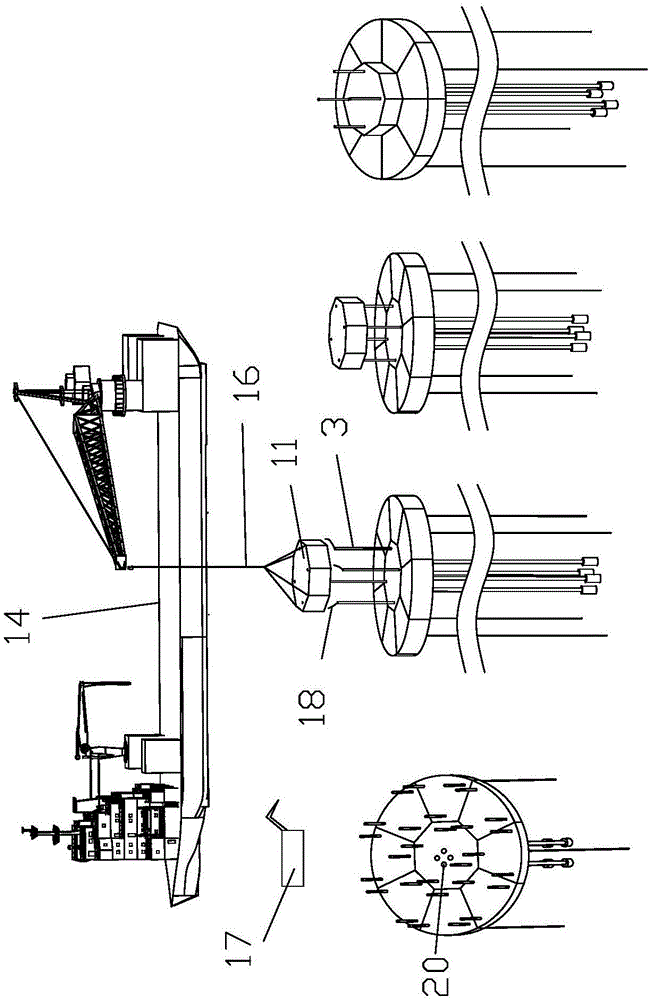

[0081] Such as Figure 1-6 As shown, the modularized oil and gas production platform in water includes an upper layer functional module 1, a lower layer platform module 2, a rigid jumper 13, a wellhead head 20 in water, a rigid riser 4, mooring cables 5 and a subsea wellhead head 6; the upper layer functions Module 1 includes a mining and reinjection module 101, a collection module 102, a separation module 103, a crude oil pretreatment module 104, a natural gas pretreatment module 105, a natural gas prerefrigeration compression and output module 107, a crude oil storage module 106, and a crude oil pressurization output module 108 and the control center module 109; the lower platform module 2 includes a mooring module 201, a water wellhead module 202 and a ballast module 203;

[0082] The exploitation and reinjection module 101 carries out the exploitation of oil and gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com