Method for collecting natural gas from producing well

A technology for natural gas and production wells, which is applied in the field of perforation technology to solve the blocking and burial of production pipe strings of oil and gas wells, can solve problems such as cost increase, water flooding and decline of production layers, and achieve the effect of improving gas well productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

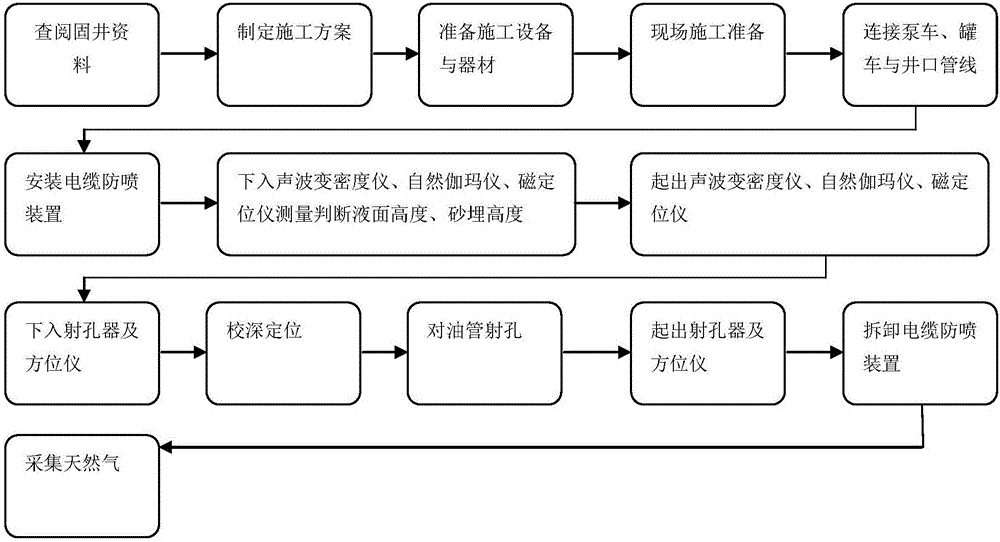

[0038] A method of collecting natural gas from a production well, comprising the steps of:

[0039] 1) Use the logging cable to lower the acoustic variable density meter, natural gamma ray meter, and magnetic positioning logging instrument into the tubing of the gas well to measure the liquid level inside the tubing and the sand burial depth outside the tubing.

[0040] 2) Determine the perforation position according to the curves measured by acoustic variable density, natural gamma ray instrument, and magnetic positioning logging tools. The principles for determining the perforation position are firstly to avoid tubing 14 and casing 9 couplings, secondly to avoid the sand-buried position, which is above the sand-buried position, and thirdly to select well sections with good cementing quality. After the above three points are satisfied at the same time, the perforation position should be as low as possible, close to the gas layer position. The well intervals with good cementi...

Embodiment 2

[0045] 1) Preparation stage:

[0046] 1.1) Construction wells should be completed with Φ139.7mm casing, gas production string Φ73 tubing and throttle valve (or without throttle valve) production mode, tubing inner diameter 62mm, wall thickness 5.51mm, height of liquid column in tubing Conditions below 500m, sand buried no more than 30m, and wellhead pressure less than 35MPa.

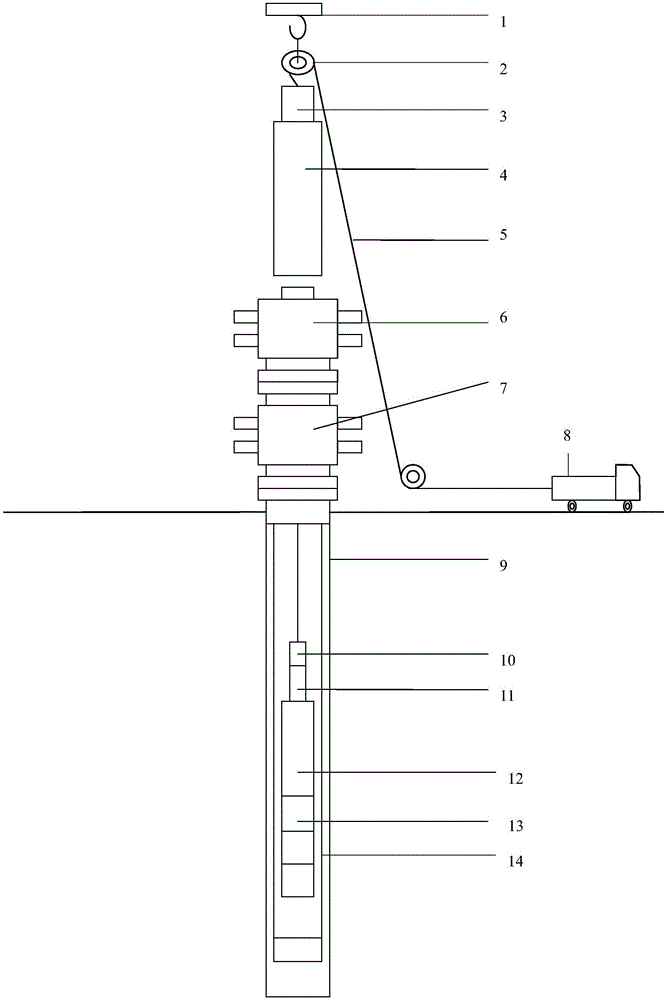

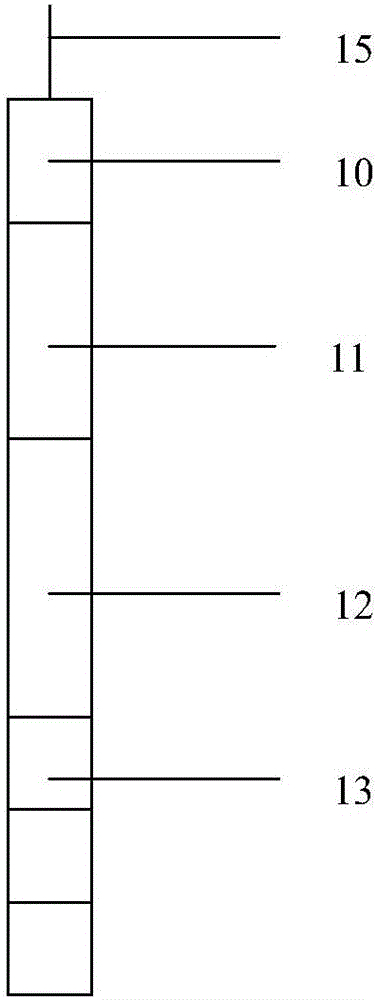

[0047] 1.2) The construction should be equipped with logging truck 8, Φ8mm single-core logging cable 5, cable protection device 10, horse bridle, Φ51mm variable density logging instrument, natural gamma meter, magnetic positioning instrument, and pressure resistance greater than 35MPa suitable for 5- 8mm cable perforation blowout preventer, cable perforation blowout preventer, perforator, weight bar 13, pump truck, water tank truck, crane and other equipment and instruments. The cable perforation blowout preventer includes a control head 3 , a blowout preventer 4 , a cable blowout preventer 6 and a dril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com