A method to realize coalbed surface gas wetting reversal and improve production of coalbed methane wells

A wetting reversal and coal seam technology, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as expansion, cleat porosity and permeability decrease, so as to prevent clogging and improve Yield, effect of preventing expansion of matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The gas wetting inversion treatment agent is a methanol solution composed of Pingpinga O-10 and fluorocarbon surfactant perfluorooctyl sulfonamide propyl amine oxide, Pingpinga O-10 and perfluorooctyl sulfonamide propyl The amine mass ratio is 3:7, and the solution concentration is 0.1%.

[0038] Coal seam surface gas wetting reversal test method: Firstly, the surface of the coal sample is polished smooth, and then cleaned with ethanol and acetone. Soak in the air-wetting inversion treatment agent, treat at 25°C for 3 hours, and then dry at room temperature.

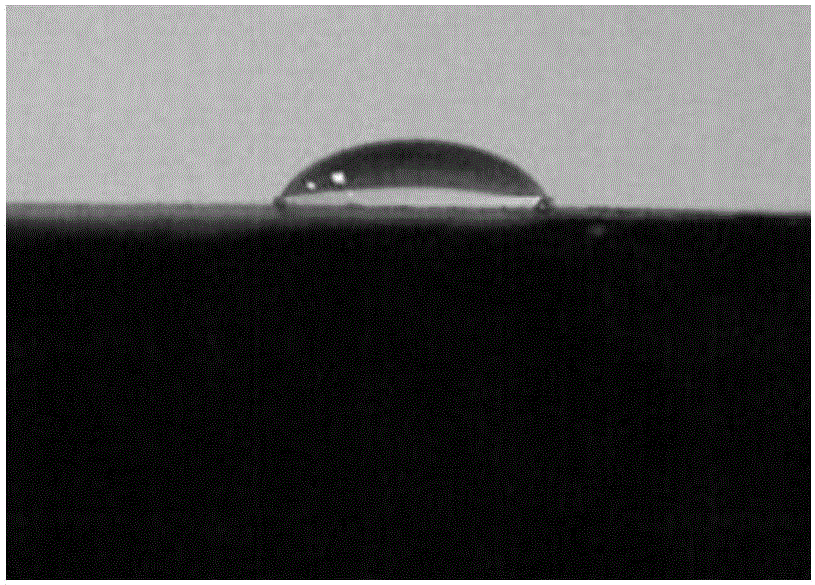

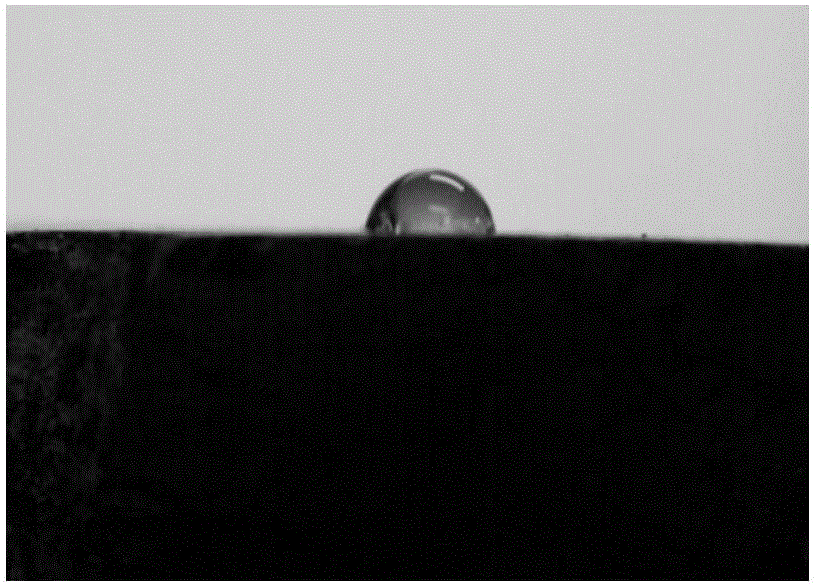

[0039] In this embodiment, the surface contact angle of the coal sample after the treatment is measured, and the contact angle of the water\air\coal sample system is 103°, such as image 3 As shown, the contact angle of n-decane\air\coal sample system is 94°, such as Figure 4 shown.

Embodiment 2

[0041] As described in Example 1, the difference is that the concentration of the gas-wetting inversion treatment agent solution is 0.2%.

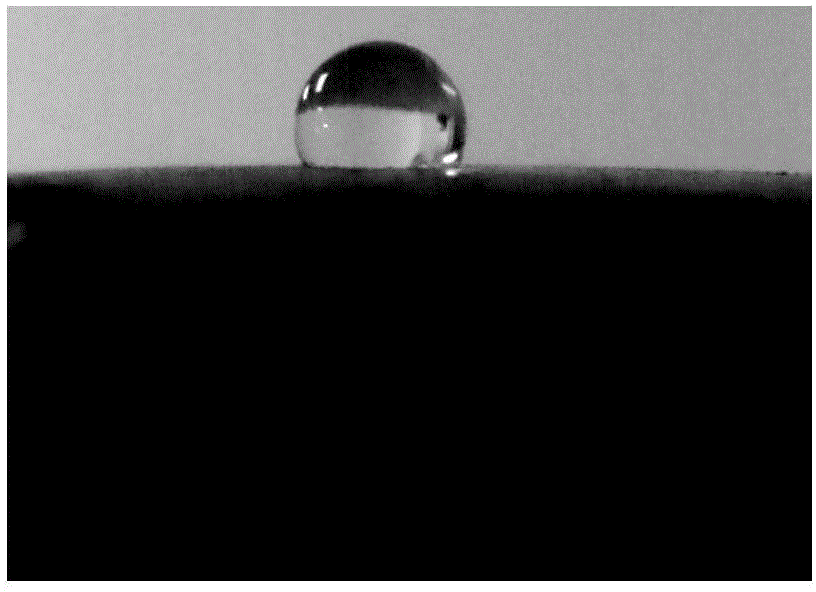

[0042] This embodiment measures the surface contact angle of the coal sample after treatment, and the contact angle of the water\air\coal sample system is 106°, such as Figure 5 As shown, the contact angle of n-decane\air\coal sample system is 98°, such as Figure 6 shown.

Embodiment 3

[0044] As described in Example 1, the difference is that the concentration of the gas-wetting inversion treatment agent solution is 0.3%.

[0045] In this embodiment, the surface contact angle of the treated coal sample is measured, the contact angle of the water\air\coal sample system is 102°, and the contact angle of the n-decane\air\coal sample system is 91°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com