Hybrid and intelligent updating method for boiler efficiency combustion optimization model

A boiler efficiency and boiler combustion technology, which is applied in the control of combustion, lighting and heating equipment, etc., can solve problems such as degeneration, difficulty, and the problem of boiler combustion optimization not being well solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

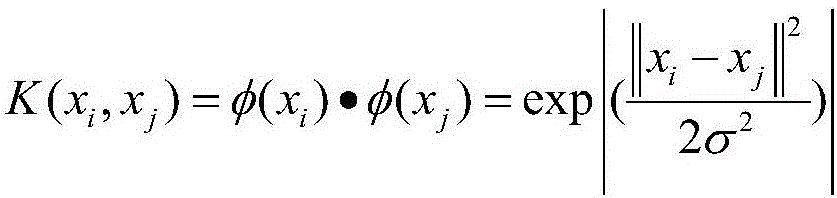

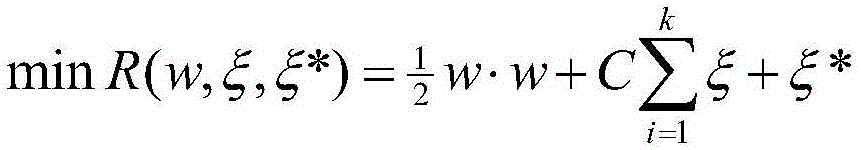

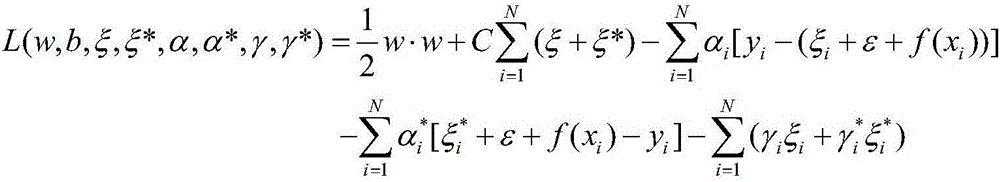

[0040] A hybrid intelligent boiler efficiency combustion optimization model updating method, specifically the following steps:

[0041] (1) Based on boiler combustion professional knowledge and experimental research, construct standard indicators that are positively correlated with boiler combustion efficiency where ΔT=T 1 -T 2 ,T 1 It is the characterizing temperature of the furnace, which can be measured by a non-contact temperature measuring instrument, such as an infrared non-contact temperature measuring instrument, or obtained by a boiler combustion DCS system, T 2 It is the characteristic temperature of the tail flue, which can be taken as the temperature after the air preheater or the temperature after the economizer, which can be obtained from the DCS system of the boiler combustion or directly measured; k* is the design coal type of the power plant boiler to produce flue gas per ton of coal combustion Coefficient, which is related to coal quality and can be calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com