Urea liquid level sensor test system

A testing system and sensor technology, applied in testing/calibration devices, liquid/fluid solid measurement, instruments, etc., can solve the problems of large urea level measurement error, low detection accuracy, and excessive resistance output value deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described.

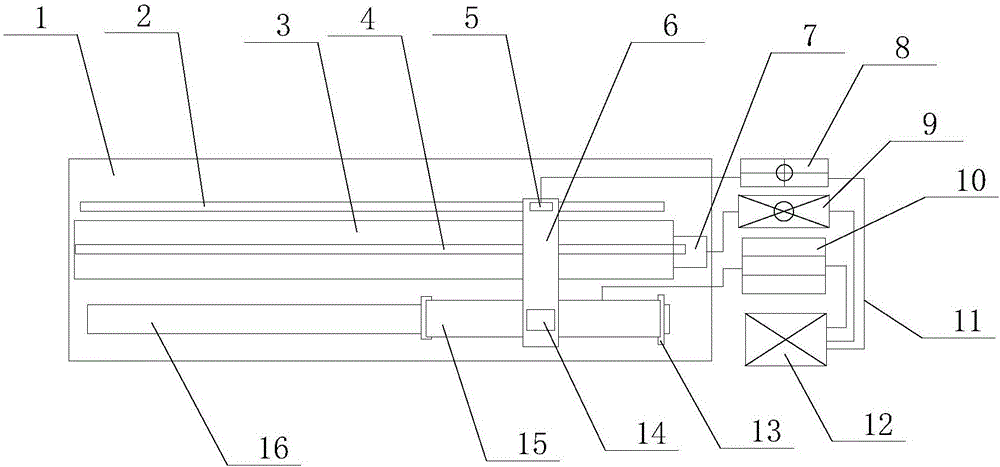

[0020] see figure 1 As shown, the technical solution adopted in this specific embodiment is: it includes a marble platform 1, a grating ruler 2, a linear guide rail 3, a guide rail screw 4, a guide rail slider 6, a stepper motor 7, a product mounting bracket 16, and a urea liquid level Sensor product 15, floating ball 14, multimeter 10; described grating ruler 2 is attached on the marble platform 1; grating ruler 2 is provided with grating ruler reading head 5; grating ruler reading head 5 is connected with grating reading module 8; The linear guide rail 3 is arranged on the marble platform 1; the linear guide rail 3 is arranged on the side of the grating ruler 2; the guide rail slider 6 is arranged on the linear guide rail 3; The terminal is connected to the stepper motor 7; the stepper motor 7 is connected to the motor control module 9; the grating ruler reading head 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com