Fiber Bragg Grating Two-Dimensional Vibration Sensor with Adjustable Range

A fiber grating and two-dimensional vibration technology, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of different sensitivity, potential safety hazards, small measurement range, etc., and achieve large contact area, easy positioning and stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

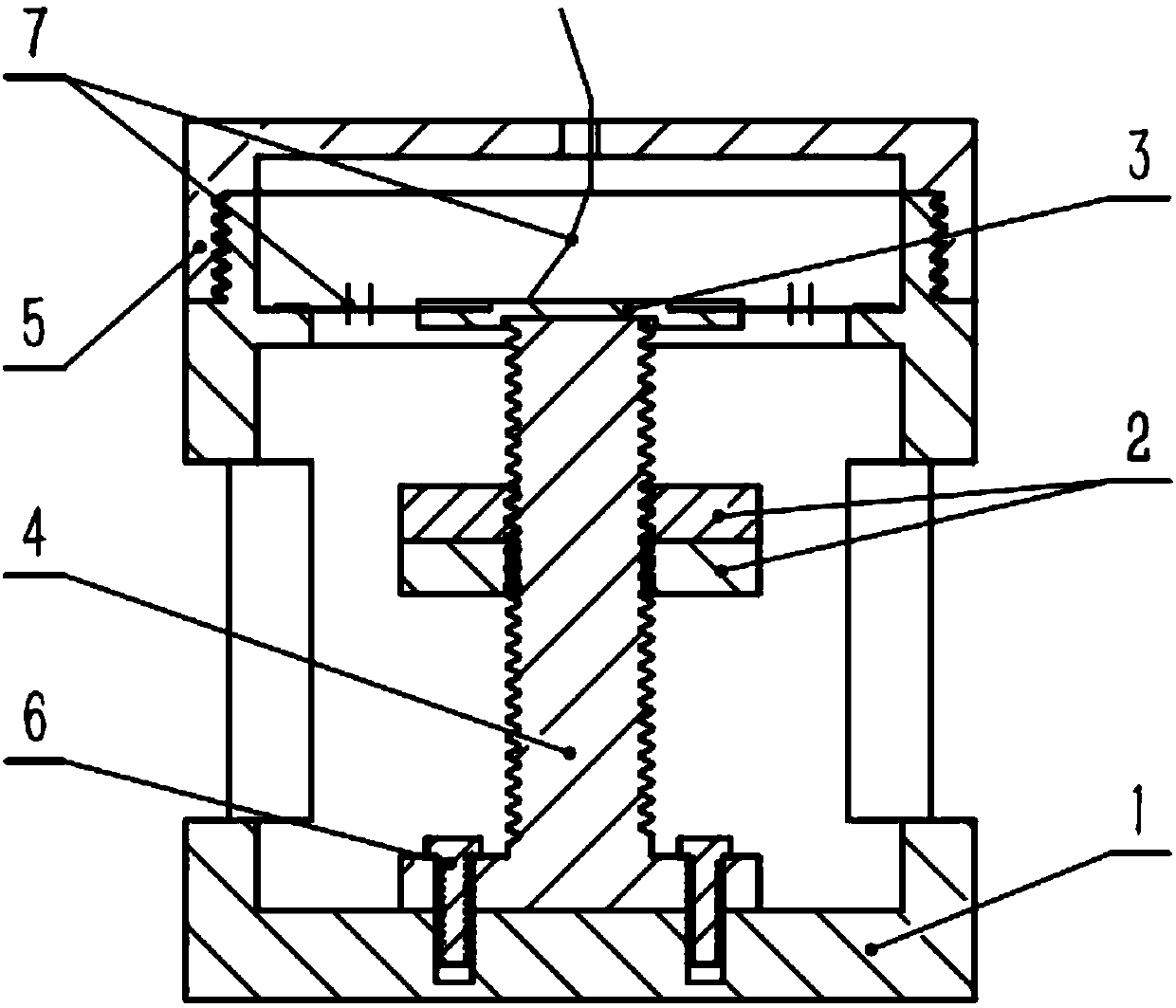

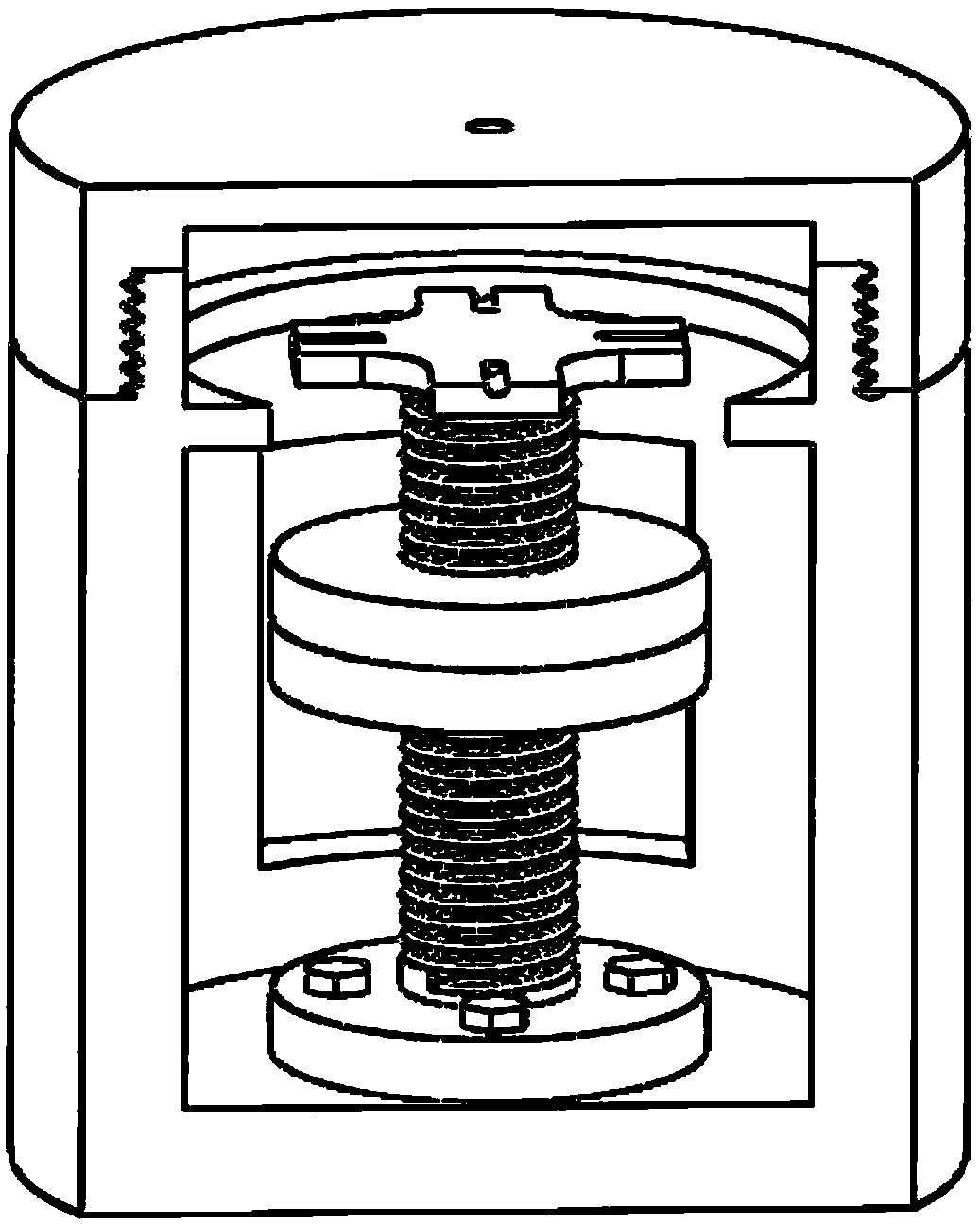

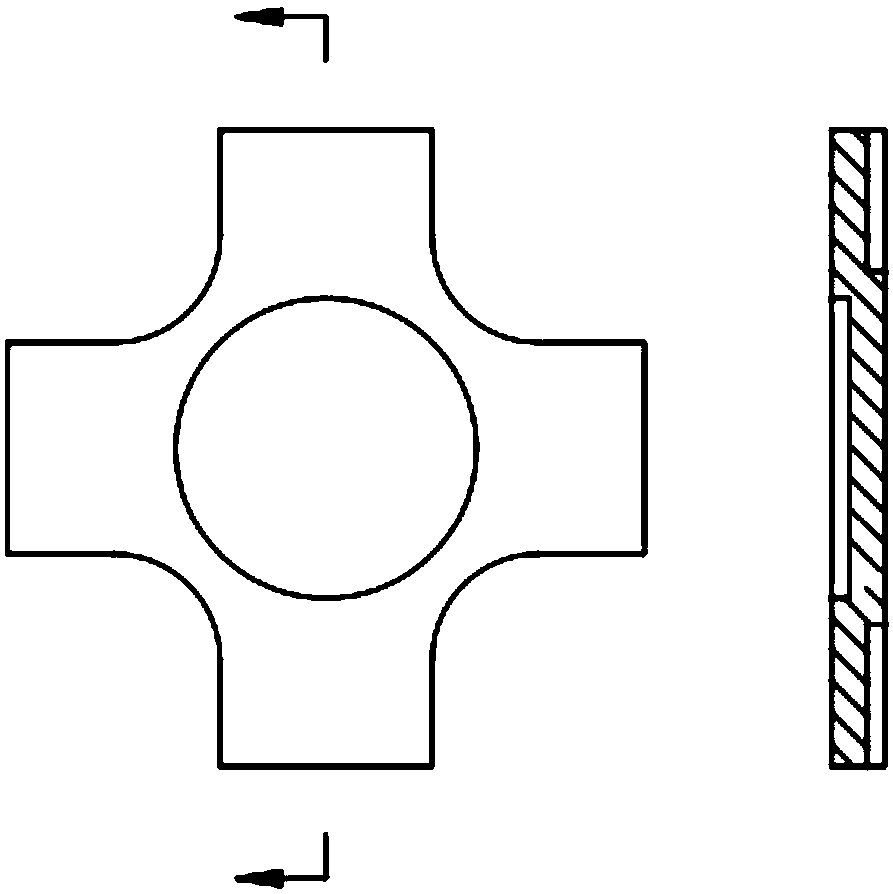

[0030] Such as figure 1 and figure 2 As shown, a fiber grating 7 two-dimensional vibration sensor with adjustable range includes a cylindrical and hollow base 1, the inner surface of the base 1 is provided with a convex ring, and the inner bottom surface is fixed with a coaxial threaded round rod 4 ( The threads are all over the round rod, or at least the stroke of the quality ring 2 is full of threads), and the middle part of the threaded round rod 4 is fitted with a pair of quality rings 2 through threads (the two quality rings 2 are the same, and the position is adjusted by the threads. Tighten the surface of the two mass rings 2 to closely contact to realize self-locking), the top is fixed with a coaxial optical fiber fixing plate 3, and a fiber grating 7 is fixed on the fiber fixing plate 3 and the convex ring, and the fiber grating 7 is sequenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com