Quantitative analysis method for continuous casting billet dendritic segregation

A technology of dendrite segregation and quantitative analysis, which is applied in the direction of analyzing materials, using wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of time-consuming, random, inaccurate quantitative analysis, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 380

[0024] This embodiment takes the 380CL wheel steel continuous casting slab as an example.

[0025] 1. Sample preparation:

[0026] First cut a block sample from the area near the center of the 380CL slab. The size of the sample is: 30mm long x 18mm wide x 20mm thick. Then the sample is cleaned, ground and polished and put into the electronic probe sample room for observation. test.

[0027] 2. Electron probe surface analysis:

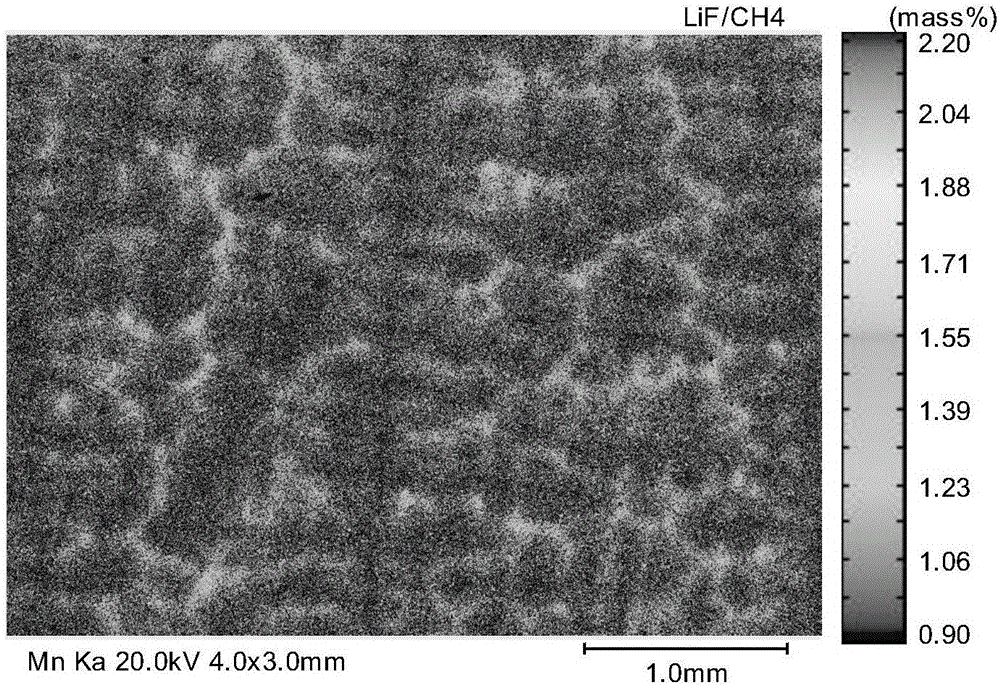

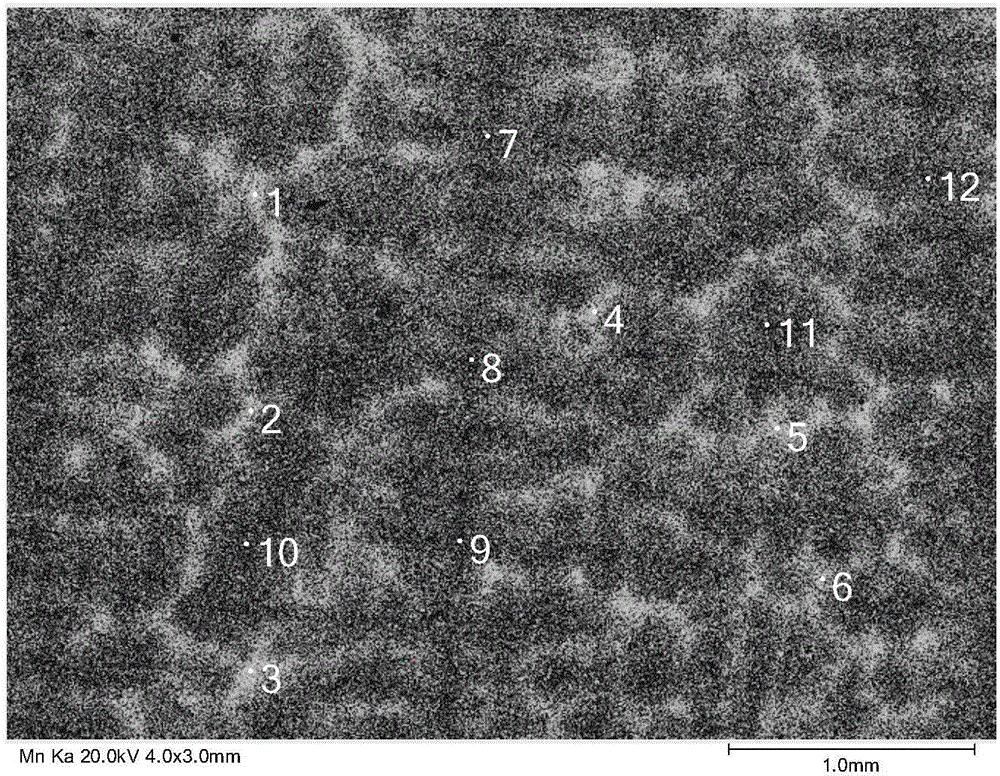

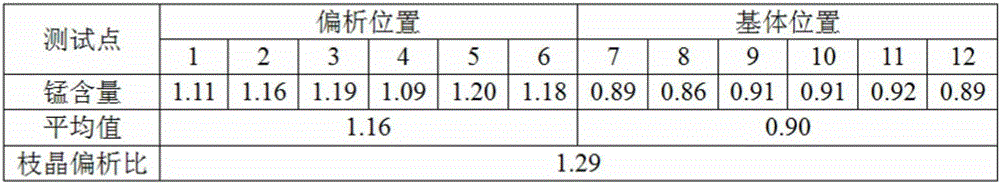

[0028] (1) Open the "Mapping" module of the electron probe analysis software, select the Mn element as the analysis element, set the acceleration voltage to 20KV, the beam current to 400nA, the beam spot size to 1μm, select the analysis area of 4mm×3mm, and click "Operate" to analyze the Mn element. face scan analysis.

[0029] (2) After the analysis is completed, click the "color setting" icon to optimize the color of the surface analysis diagram of the Mn element with a content range of 0 to 100%. The segregation content of the Mn element is abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com