Fluorescent wheel and two-color laser source

A laser light source and fluorescent wheel technology, which is applied in the field of fluorescent wheels and two-color laser light sources, can solve the problems of unfavorable laser equipment miniaturization and large light source volume, and achieve the effect of improving light processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

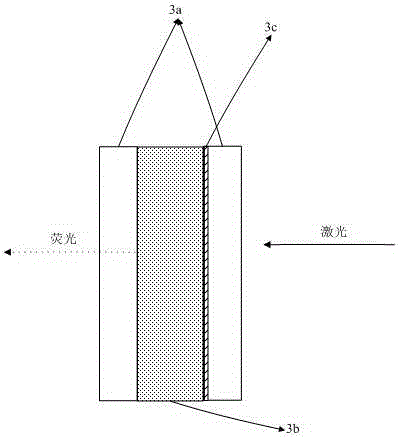

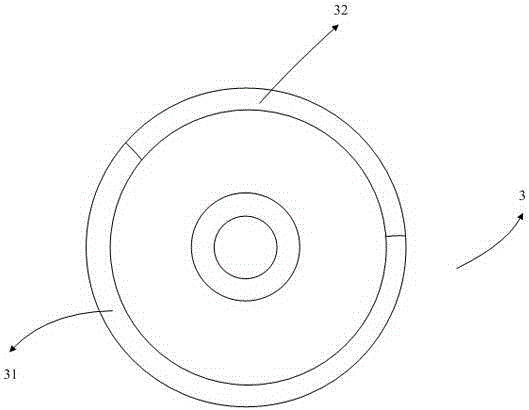

[0046] Embodiment 1 of the present invention provides a fluorescent wheel, driven by a motor to rotate, such as image 3 As shown, the fluorescent wheel 3 is disc-shaped and includes a fluorescent area 31 and a non-fluorescent area, wherein the non-fluorescent area includes a central motor shaft area and a transmissive area 32 . Among them, such as Figure 7As shown, the fluorescent area 31 includes a green fluorescent layer 311 and a coating layer 312 on the green fluorescent layer 311 . Among them, the green fluorescent layer 311 of the fluorescent area 31 is used to accept the excitation of the incident laser excitation light to generate fluorescence, and the transmissive area 32 is not provided with phosphor powder, which is used to provide an independent channel for the transmission of the laser light, so that when the laser light source rotates on the fluorescent wheel The non-fluorescent excitation time period of the laser light includes a laser excitation light source...

Embodiment 2

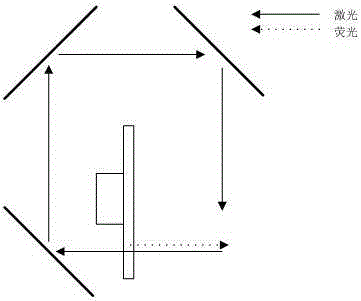

[0062] Embodiment 2 of the present invention provides a two-color laser light source, such as Figure 9 As shown, it includes a laser light source unit 1, including a blue laser and a red laser, which emit blue laser and red laser respectively; The large laser spot is focused, and the small spot reduced to a set size is incident on the fluorescent wheel 3 .

[0063] Among them, the fluorescent wheel 3 is the fluorescent wheel described in Embodiment 1, and the fluorescent wheel 3 includes a green phosphor area. Because the blue laser has a short wavelength, according to the principle of energy transition and wavelength conversion, a blue laser with a shorter wavelength is selected as the excitation. light to excite the green fluorescent powder to produce green fluorescence; wherein, the substrate in the green fluorescent powder area on the fluorescent wheel 3 is a transparent substrate, and the blue laser light-incident side of the transparent substrate is coated with a wavele...

Embodiment 3

[0080] Embodiment 3 of the present invention is a modification or improvement on the basis of Embodiment 2, and the same parts and beneficial effects as Embodiment 2 will not be repeated here.

[0081] The difference from Example 2 is that, as Figure 12 As shown, the blue laser 11 and the red laser 12 in the laser light source unit 1 in the embodiment of the present invention are arranged side by side, rather than vertically. It should be noted that the arrangement of the blue laser and the red laser does not affect the present invention. The essential purpose of the technical solution of the invention is that when the two are vertically arranged in Embodiment 1, the heat dissipation parts for the laser light source can be arranged in the right-angled space formed by the two vertically, and the lasers of the two colors are dissipated respectively, and the lasers of the two colors are arranged side by side. When arranged, the heat dissipation part needs to be arranged above or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com