Train operation fault automatic detection system and method based on binocular stereoscopic vision

A technology of binocular stereo vision and operation failure, applied in measurement devices, material analysis through optical means, image data processing, etc., can solve the problem of failure to guarantee train failure prevention, failure to three-dimensional quantitative description of failure, failure mechanism and failure performance different forms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation examples.

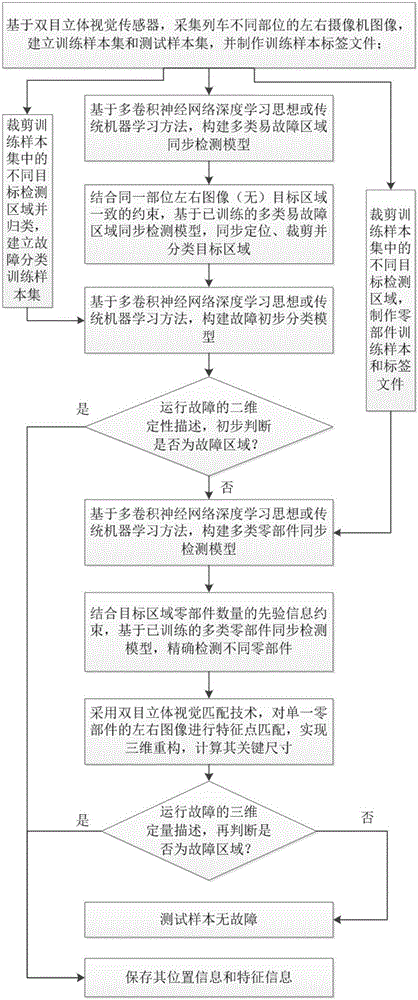

[0061] figure 1 It is an overall realization flow chart of a binocular stereo vision-based train operation failure automatic detection method and system of the present invention,

[0062] Such as figure 1 Shown, concrete realization of the present invention comprises the following steps:

[0063] Step 1: Based on the binocular stereo vision sensor, collect the left and right camera images of different parts of the train, establish a training sample set and a test sample set, and make a training sample label file; cut and classify different target detection areas of the training sample, and establish a fault classification Training sample set: Based on the different target detection areas of the cropped training samples, a component training sample set and a component training sample label file are established.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com