A stator assembly and its manufacturing method

A component and stator technology, applied in the field of stator components and its manufacturing, can solve the problems of large individual differences in motor performance and inconvenient positioning of stator cores, etc., and achieve convenient and accurate positioning, simple structure, guaranteed sealing and anti-rust capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

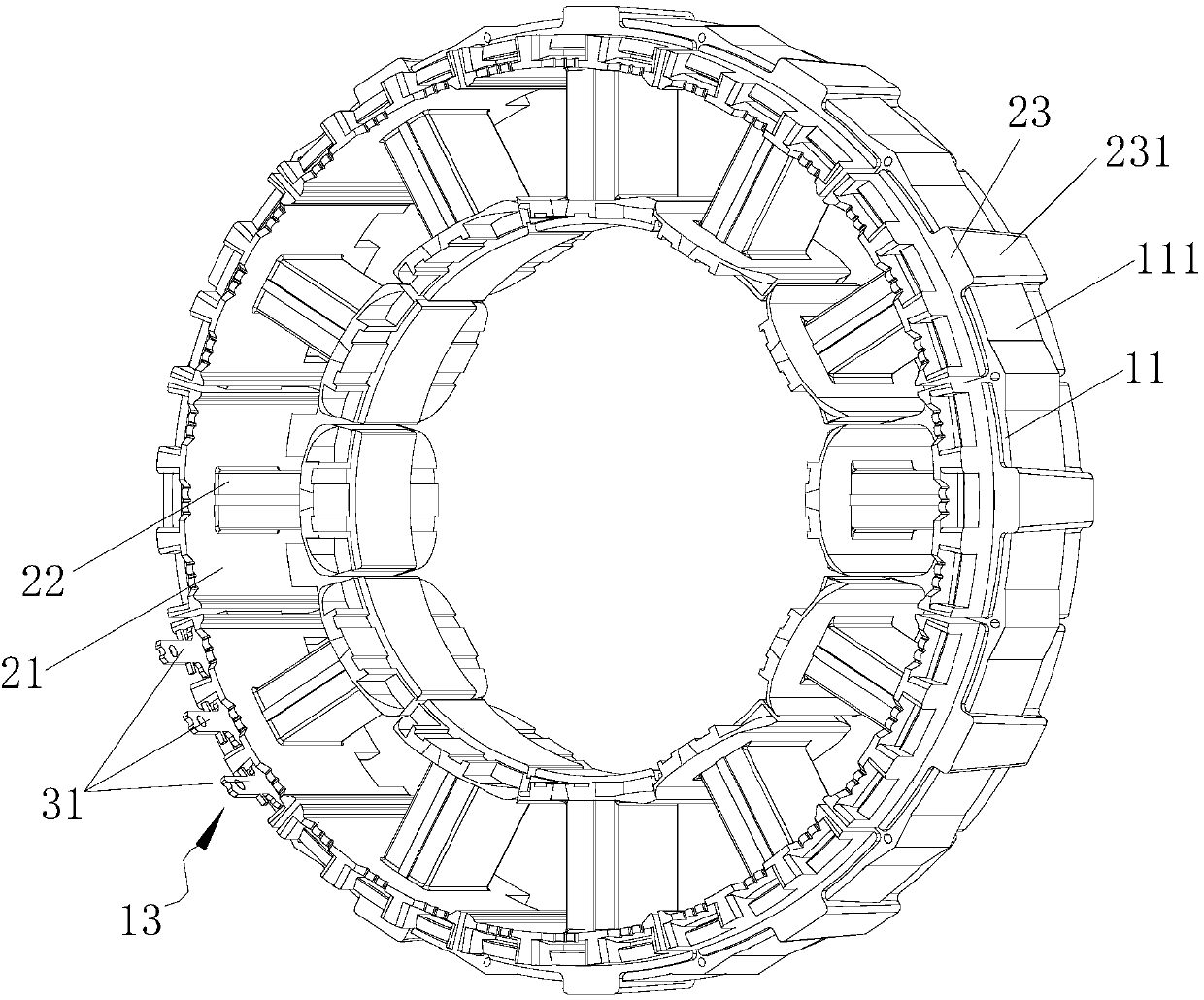

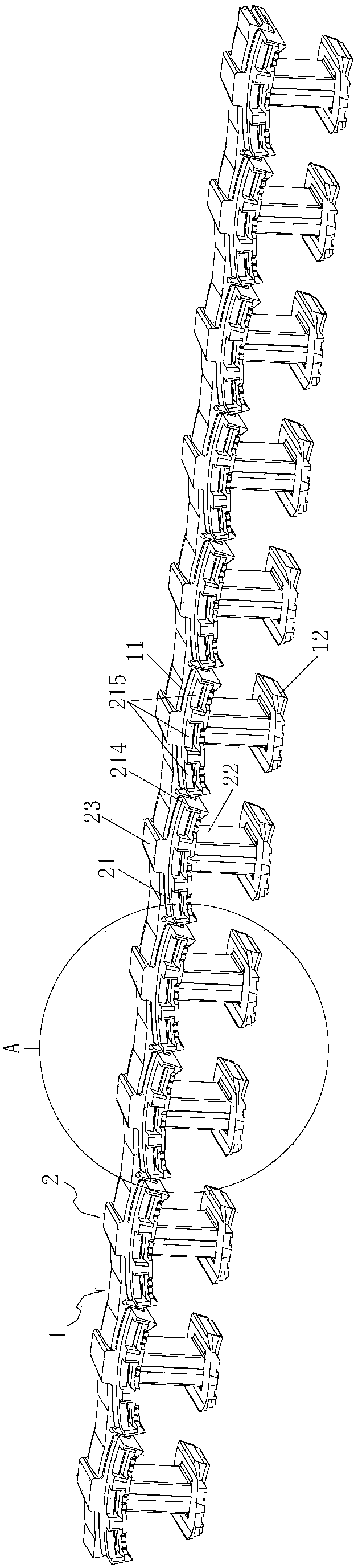

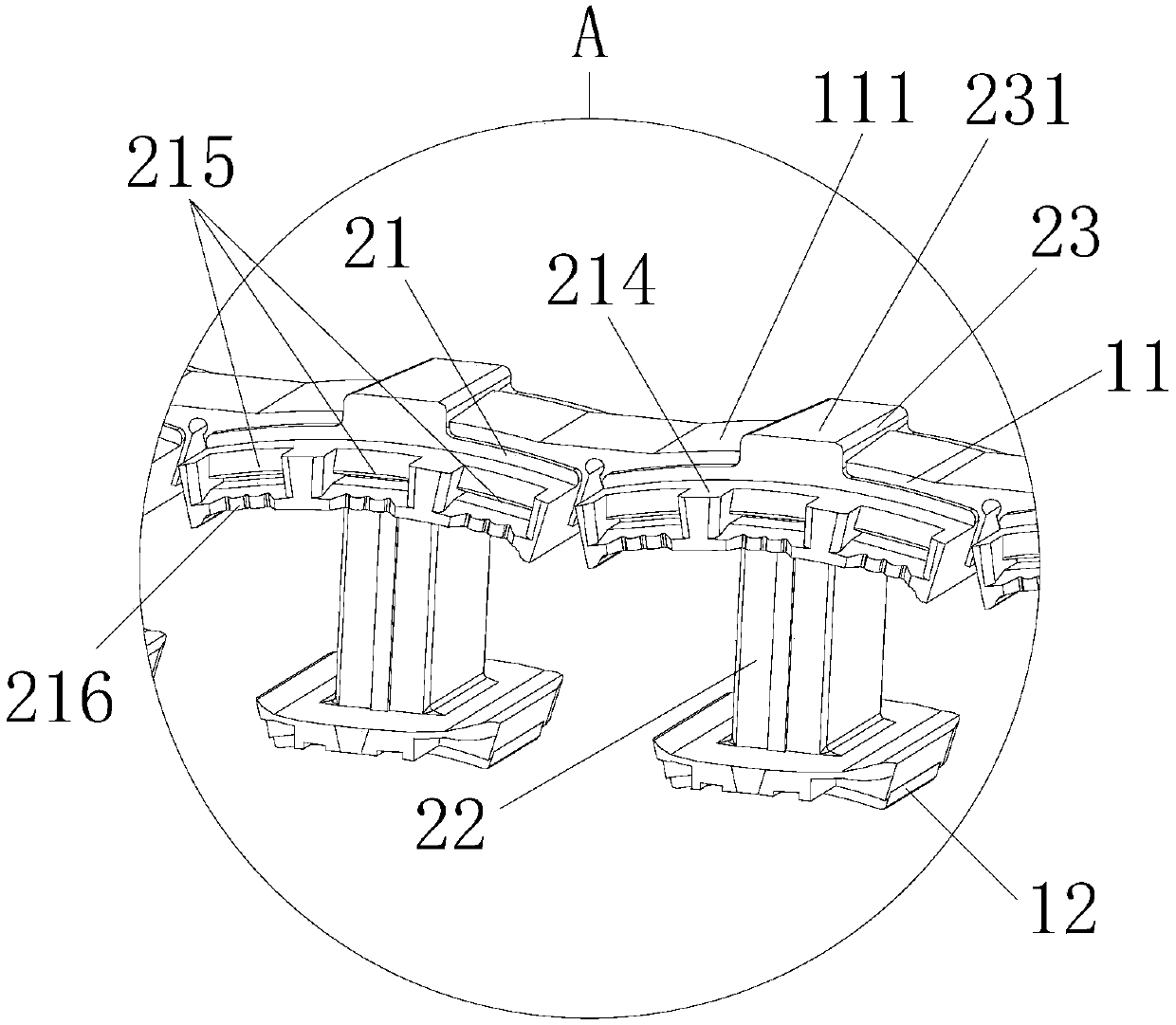

[0041] like Figure 1 to Figure 7 As shown, this embodiment provides a stator assembly, including a stator core 1, an end insulation 2 installed on the stator core 1, and a coil winding 3 wound on the end insulation 2, The stator core 1 includes a yoke 11 and several teeth 12 protruding from the inner side of the yoke 11, the end insulation 2 includes an insulating yoke 21 and an insulating tooth 22, and the insulating teeth 22 fit into Sleeved on the tooth part 12, the insulating yoke part 21 is nested on the yoke part 11, and the feature is that the end part insulation 2 also includes several positioning ribs 23, and the positioning ribs 23 protrude from the The outer surface 111 of the yoke 11 is connected to the insulating yoke 21 , and an axial inclined surface 231 is provided on the outer side of the positioning rib 23 .

[0042] The stator assembly described in this embodiment has a simple structure, the positioning ribs 23 can protect the stator core 1 , and the axial...

Embodiment 2

[0052] like Figure 8 to Figure 10 As shown, this embodiment provides a method for manufacturing a stator assembly, which is characterized in that it includes:

[0053] Step 1, end insulation injection molding: put the strip stator core 1 into the injection mold, and inject the end insulation 2 outside the strip stator core 1;

[0054] Step 2, winding: winding and installing the three-phase coil winding on the insulating tooth portion 22;

[0055] Step 3, wiring: connect the thread ends of the three-phase coil windings to the lug 31, select any stator core unit as the positioning unit 13, and install the three lugs 31 in the wiring groove 215 of the positioning unit 13;

[0056] Step 4, mold loading: roll the stator assembly into a circle and put it into the annular cavity 5 of the plastic sealing mold. The outer circular side wall 51 of the annular cavity 5 is provided with an axially inclined positioning surface 511, so that the teeth The bottom of 12 is attached to the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com