High-frequency vibration motor of electric toothbrush

A high-frequency vibration and electric toothbrush technology, which is applied to electrical components, electromechanical devices, etc., can solve problems such as complex assembly process, fatigue aging, and high noise, and achieve simple processing technology, improved yield resistance, and fewer components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

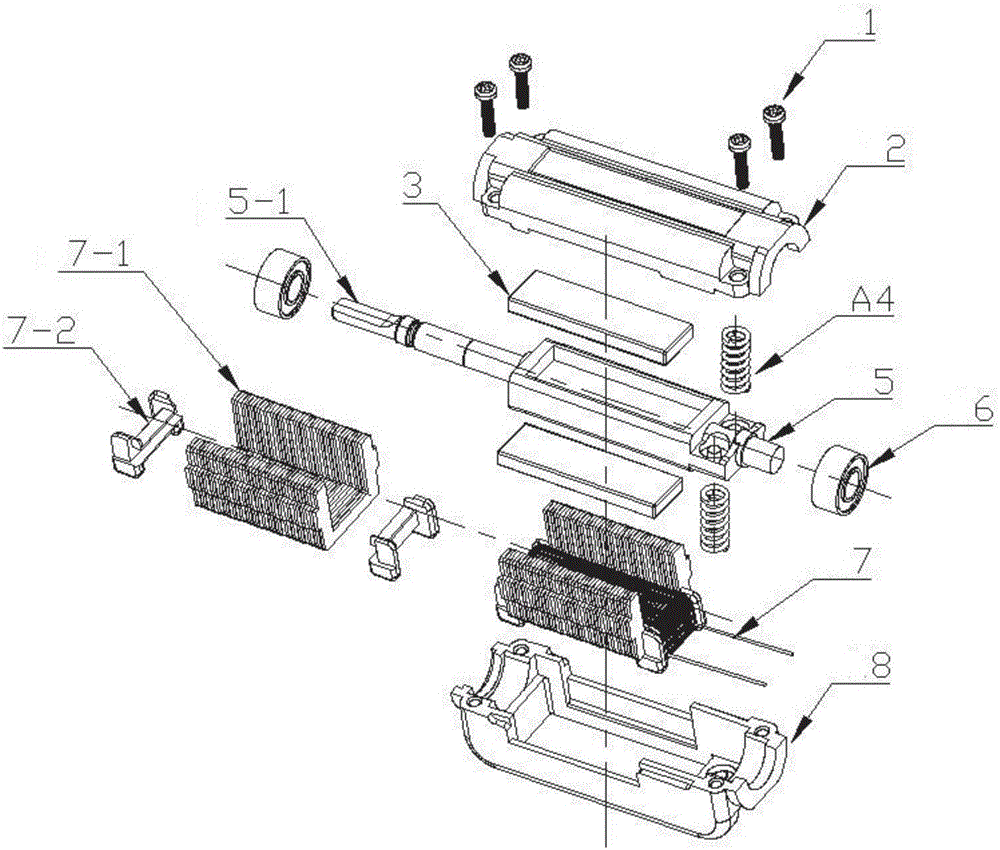

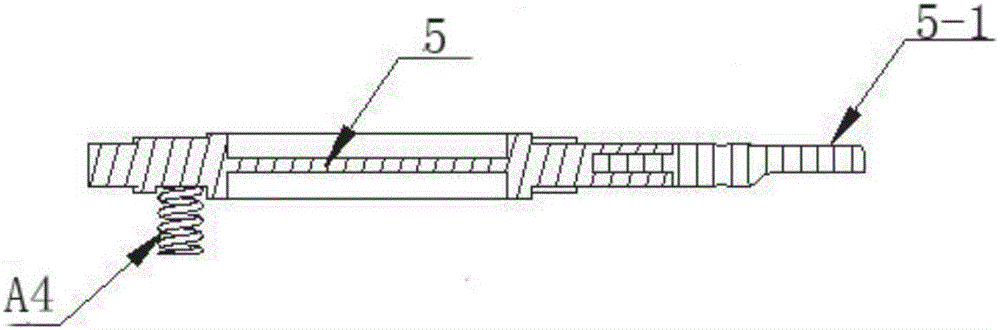

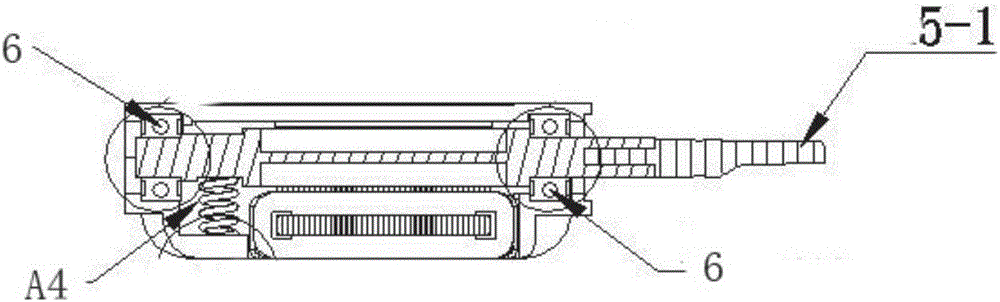

[0023] Such as figure 1 , 2 , shown in 3, a kind of electric toothbrush high-frequency vibration motor, comprises electromagnetic induction combination, stator combination, plastic upper cover 2, plastic lower cover 8 and reset structure, and electromagnetic induction combination, stator combination and reset structure are arranged on plastic upper cover 2 And in the casing that plastic lower cover 8 forms, described electromagnetic induction combination comprises iron core 7-1, wire frame 7-2 and inductor 7, and iron core 7-1 is connected with inductor 7, and iron core 7-1 is provided with wire frame 7-2, the stator combination includes a plastic bracket 5, a magnetic steel 3, a metal shaft 5-1 and a bearing 6, one end of the plastic bracket 5 is provided with a metal shaft 5-1, and the two sides of the plastic bracket 5 are respectively fixed with magnetic steel 3. The two ends of the plastic bracket 5 are fixed on the bearing 6, and the stator assembly is provided with a r...

Embodiment 2

[0029] Such as Figure 4 , 5 , shown in 6, a kind of electric toothbrush high-frequency vibration motor, comprises electromagnetic induction combination, stator combination, plastic upper cover 2, plastic lower cover 8 and reset structure, electromagnetic induction combination, stator combination and reset structure are arranged on plastic upper cover 2 And in the casing that plastic lower cover 8 forms, described electromagnetic induction combination comprises iron core 7-1, wire frame 7-2 and inductor 7, and iron core 7-1 is connected with inductor 7, and iron core 7-1 is provided with wire frame 7-2, the stator combination includes a plastic bracket 5, a magnetic steel 3, a metal shaft 5-1 and a bearing 6, one end of the plastic bracket 5 is provided with a metal shaft 5-1, and the two sides of the plastic bracket 5 are respectively fixed with magnetic steel 3. The two ends of the plastic bracket 5 are fixed on the bearing 6, and the stator assembly is provided with a rese...

Embodiment 3

[0035] Such as Figure 7 As shown, a high-frequency vibration motor for an electric toothbrush includes an electromagnetic induction combination, a stator combination, a plastic upper cover 2, a plastic lower cover 8 and a reset structure, and the electromagnetic induction combination, the stator combination and the reset structure are arranged on the plastic upper cover 2 and the plastic upper cover 2. In the housing formed by the lower cover 8, the electromagnetic induction combination includes an iron core 7-1, a wire frame 7-2 and an inductance 7, the iron core 7-1 is connected with the inductance 7, and the iron core 7-1 is provided with a wire frame 7 -2, the stator combination includes a plastic bracket 5, a magnetic steel 3, a metal shaft 5-1 and a bearing 6, one end of the plastic bracket 5 is provided with a metal shaft 5-1, and the two sides of the plastic bracket 5 are respectively fixed with a magnetic steel 3, The two ends of the plastic bracket 5 are fixed on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap