A fourteen roller rolling mill

A rolling mill and roll system technology, which is applied in the field of fourteen-high hot-rolled strip mills, can solve the problems of excessively large diameters of backup rolls, excessive backup rolls, increased consumption of rolls, etc., and achieve the effect of improving rolling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

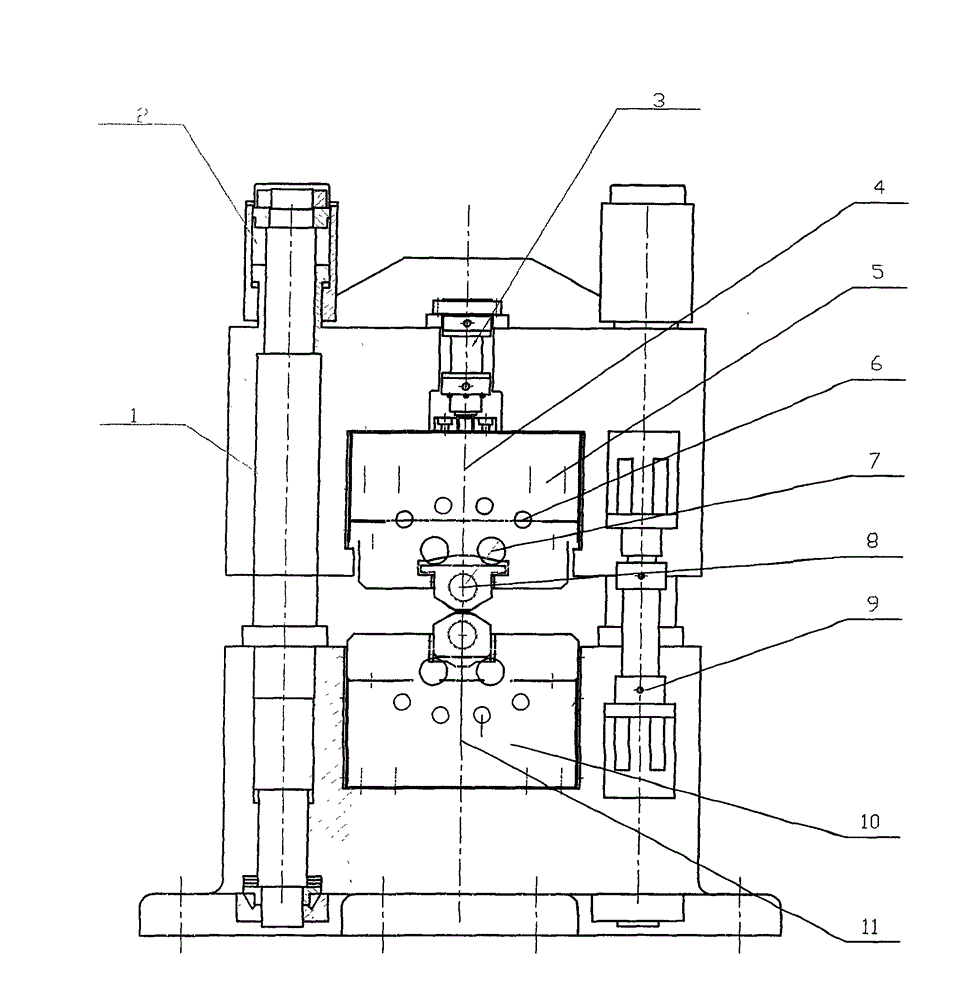

[0020] A fourteen-high rolling mill includes a frame 1, a pressing system 2, a balance device 9, a locking device 3, an upper roll system 4 and a lower roll system 11.

[0021] The depressing system 2 is composed of two sets of depressing mechanisms, which are installed on the top of the frame 1 . The pressing mechanism acts on the upper roll system 4 to adjust the roll gap between the working rolls.

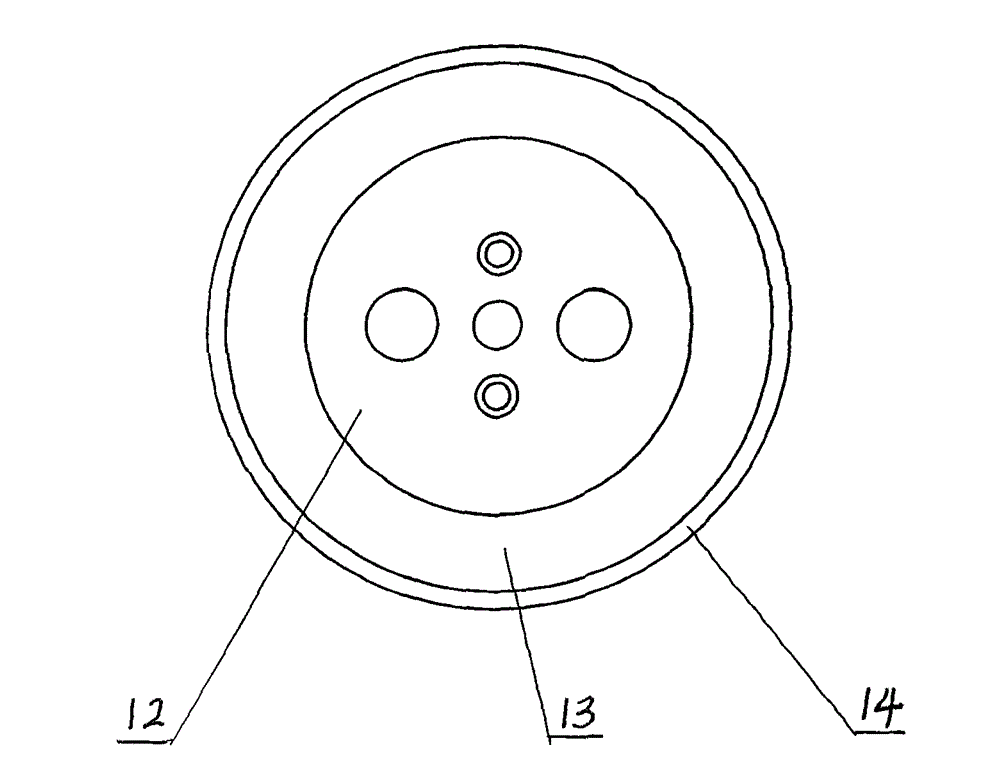

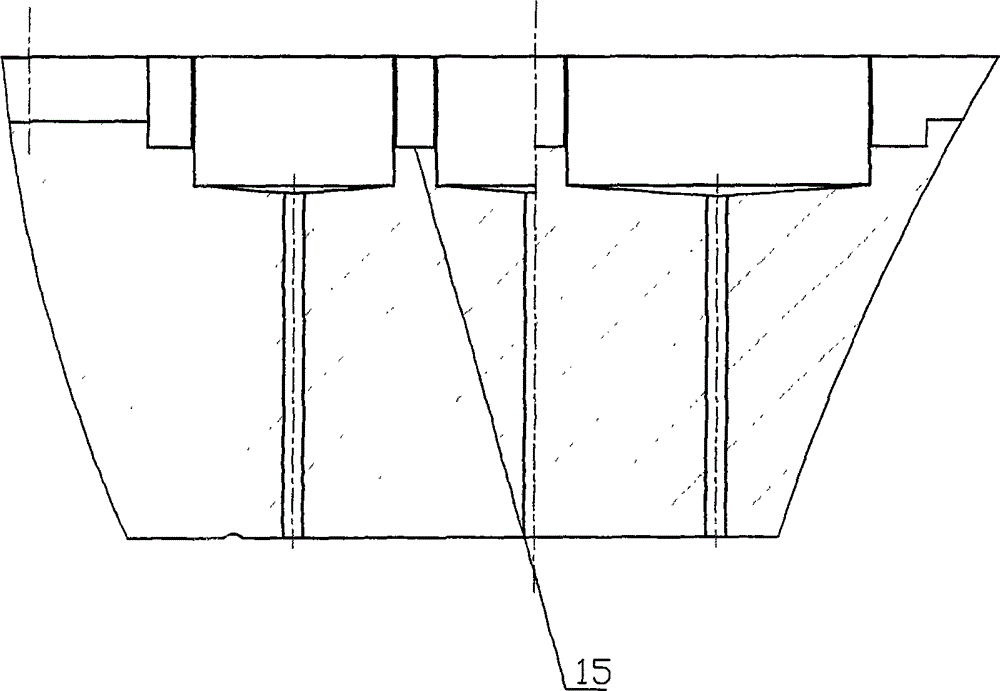

[0022] The upper roll system 4 is composed of an upper gland, four support rolls 6, two intermediate rolls 7 and a work roll 8. The upper gland 4 and the four support rollers 6 constitute a segmentally supported upper support system. The back-up roll 6 is a full-length roll shaft 12, on which 14 or 15 sets of oil film bearings 13 are installed, and the number of oil film bearings of the four back-up rolls 6 is 14, 15, 14, 15, and the oil film A wear-resistant sleeve 14 is installed outside the outer ring of the bearing 13, and the support roller 6 is installed in the support r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com