Grinding disc with internal flow supply structure

A grinding disc and liquid supply technology, applied in abrasives, manufacturing tools, bonded grinding wheels, etc., can solve problems such as uncontrollable consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the purpose, characteristics and effects of the present invention, the present invention will be described in detail through the following specific embodiments and accompanying drawings, as follows:

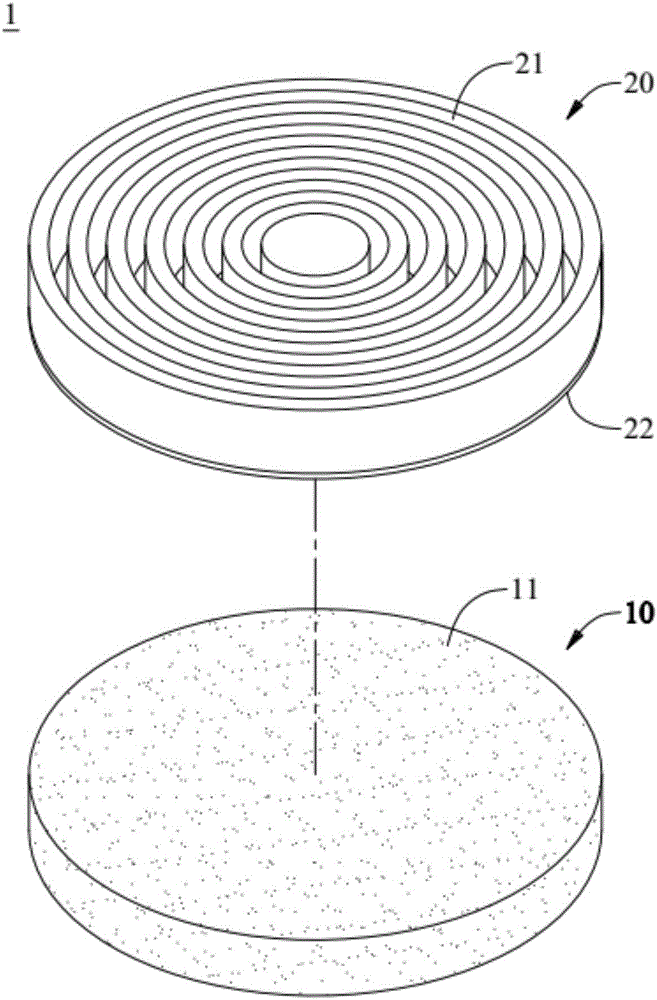

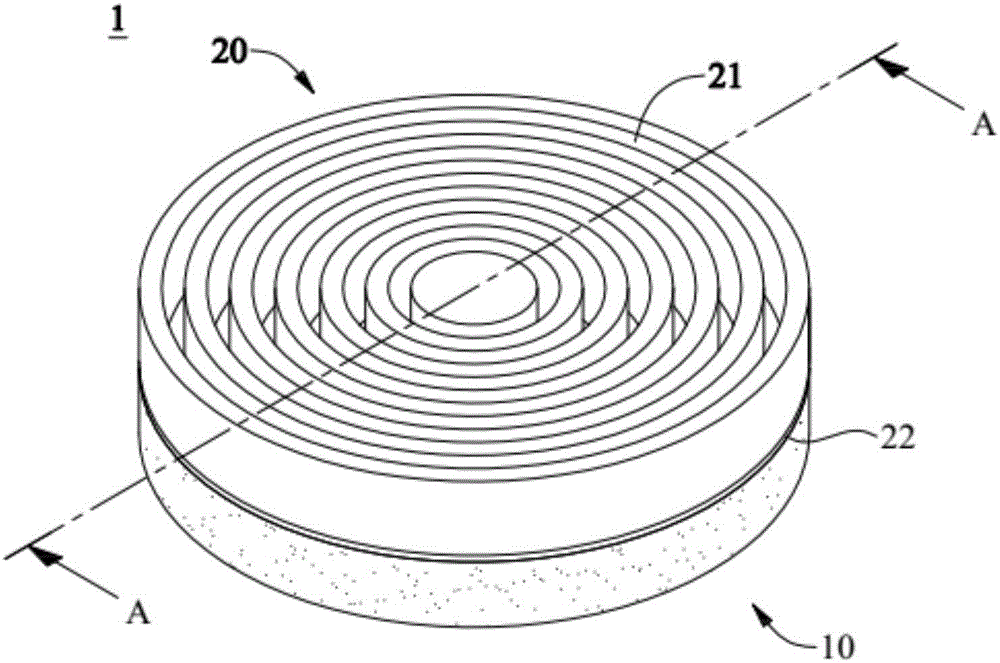

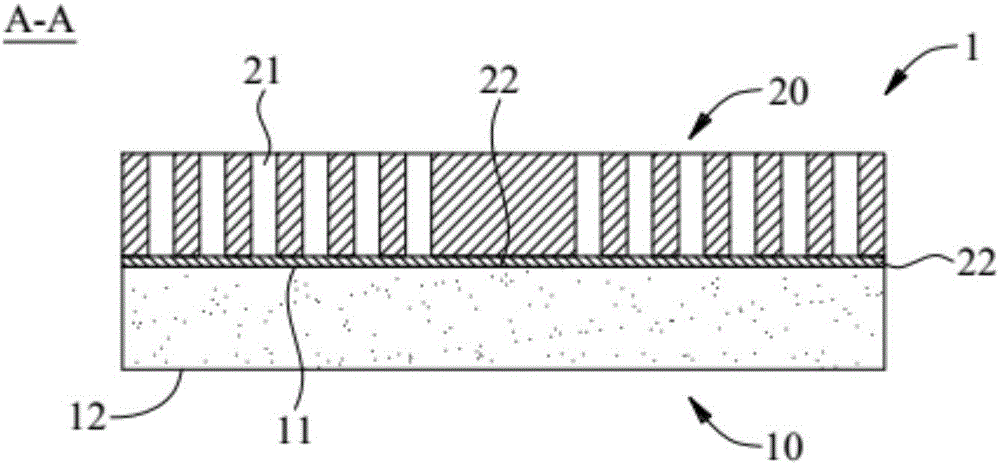

[0030] Please refer to Figures 1 to 3 , the grinding disc 1 with an internal fluid supply structure according to the embodiment of the present invention includes a porous grinding layer 10 and a base 20, and the porous grinding layer 10 includes an opposite bonding surface 11 and a grinding surface 12 ( image 3 ); the base 20 is combined on the joint surface 11, the base 20 includes a plurality of passages 21 passing through it, the passages 21 are arranged in the form of concentric circles, and at least a part of the passages 21 extending to the edge of the joint surface 11. The "fluid" can be cutting fluid, cooling liquid (such as: cooling water), cooling gas (such as: inert gas), or a combination thereof; wherein, the fluid is preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com