Data collection system for vacuum low-temperature environment

A data acquisition system, vacuum cryogenic technology, applied to parts of thermometers, thermometers, simulators of space navigation conditions, etc., can solve the problems of large temperature measurement range, failure to meet test requirements, large measurement errors, etc., and achieve high compatibility Effects on Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following introduces specific embodiments as the content of the present invention, and the content of the present invention will be further clarified through specific embodiments below. Of course, the description of the following specific embodiments is only to illustrate the content of different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

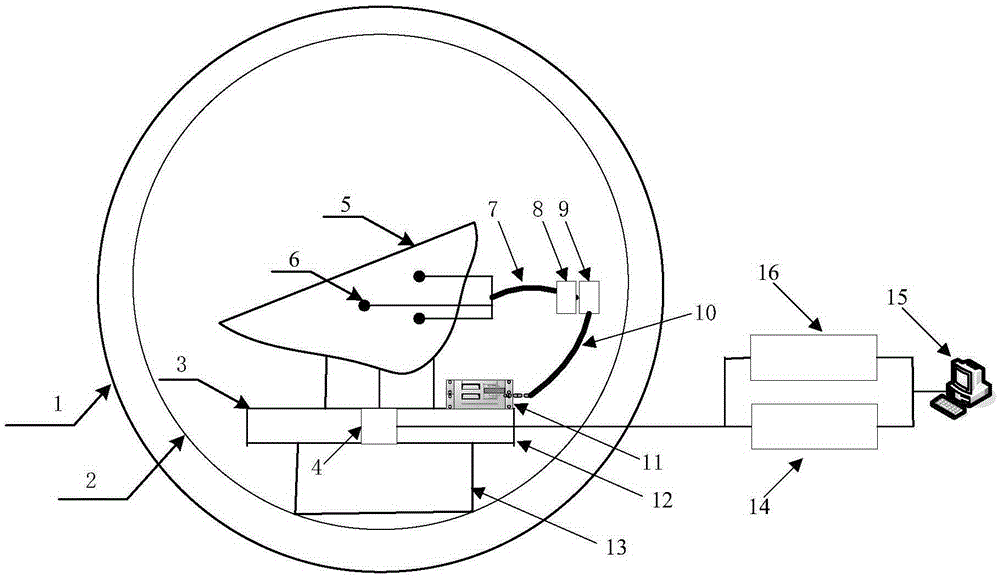

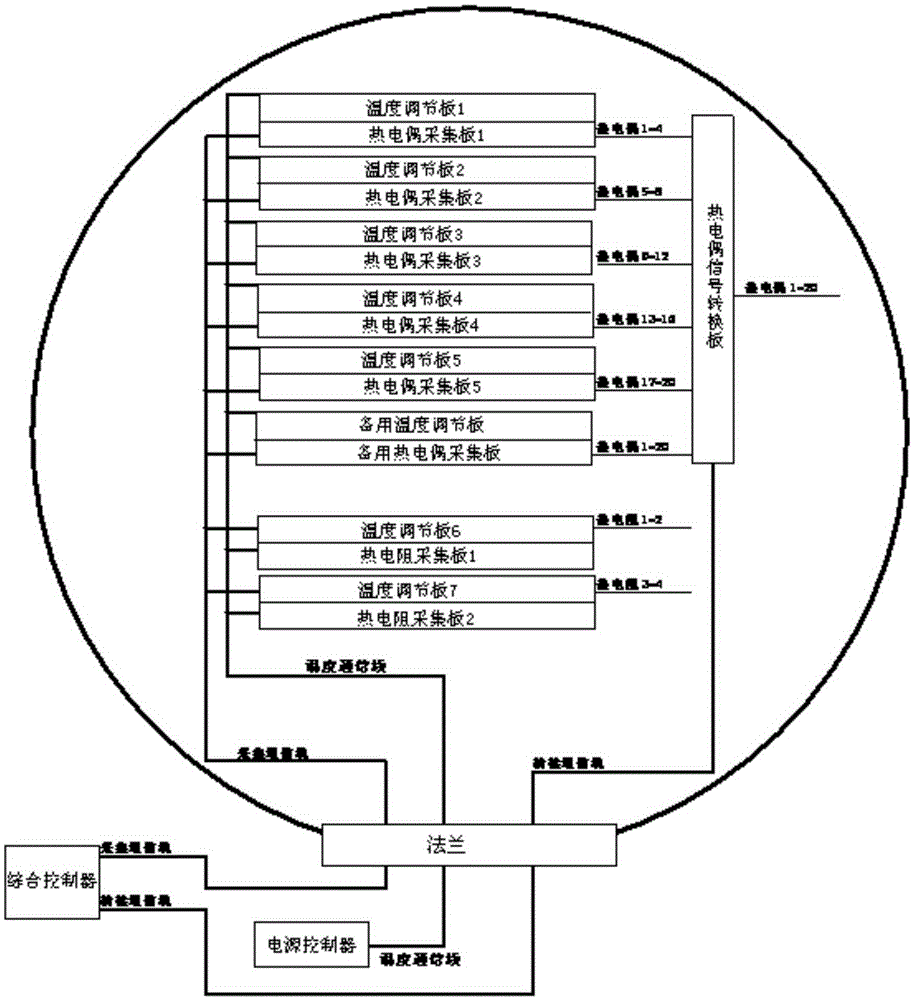

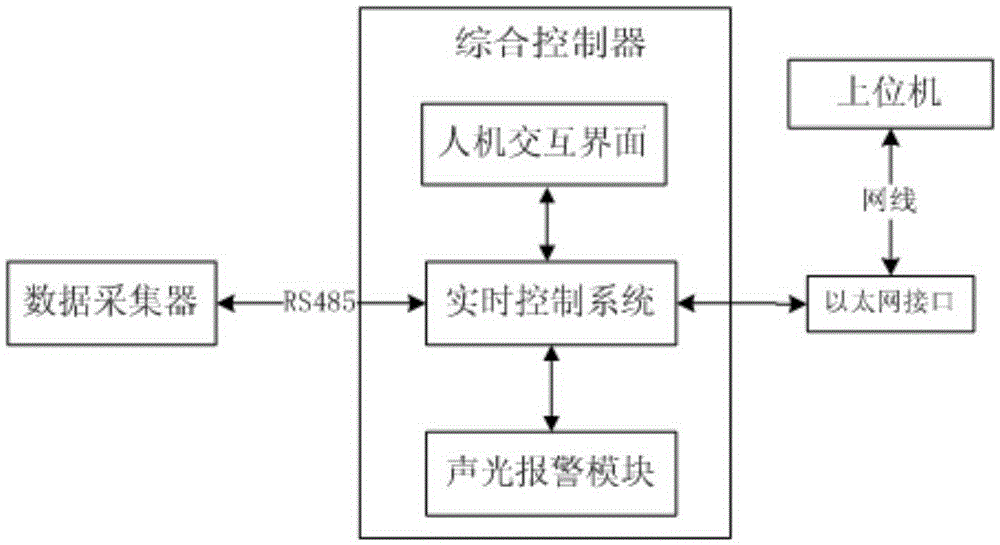

[0020] figure 1 Shown is the principle diagram of the data acquisition system for the vacuum cryogenic environment of the present invention. The data acquisition system includes a data collector 11, an integrated controller 14 and a power controller. The data acquisition system also includes vacuum vessel 1, heat sink 2, turntable 3, conductive slip ring 4, test piece 5, temperature measuring sensor 6, test piece measuring cable 7, test piece electrical connector 8, collector electrical connector 9, Collector measuring cable 10, turntable moving plate 12, turntable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com