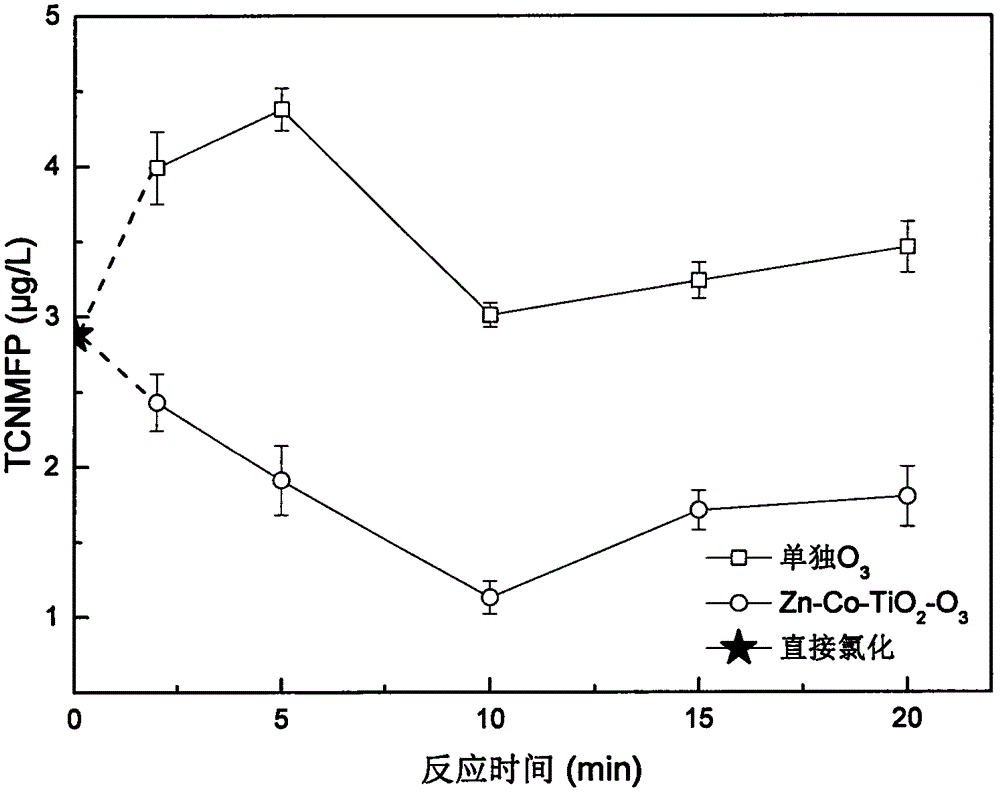

Method for controlling trichloronitromethane formation potential through catalyzing ozone oxidation

An ozone oxidation and generation potential technology, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc., can solve the problems of increased TCNM generation potential, improper use of catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The technical scheme of the invention includes the preparation of a modified nanometer metal oxide catalyst and a method for using the catalyst to suppress the formation potential of highly toxic nitrogen-containing disinfection by-product TCNM in the ozone oxidation process of nitrogen-containing water. The specific implementation is as follows:

specific Embodiment approach 1

[0016] Specific embodiment one: the preparation method of the nano-scale bimetallic doped titanium dioxide catalyst in the present invention is as follows, tert-butyl titanate is added dropwise in absolute ethanol and accompanied by continuous magnetic stirring; Add cobalt nitrate and zinc sulfate, then drop concentrated hydrochloric acid, continue to maintain magnetic stirring for 25-35 minutes, add a certain volume of distilled water, and age for 1-3 hours to obtain a gel. Among them, the ratio of butyl titanate, absolute ethanol, hydrochloric acid and distilled water is about 1:4:0.1~0.2:0.8; the ratio of Ti element in tert-butyl titanate to cobalt ion in cobalt nitrate is 15~30:1 , The ratio of Ti element in tert-butyl titanate to zinc ion in zinc sulfate is 25-45:1. Put the gel into an oven, first dry it in an environment of 60-70°C for 5-6 hours, then raise the temperature to 75-90°C and continue drying until the moisture in the gel is completely dry; put the obtained so...

specific Embodiment approach 2

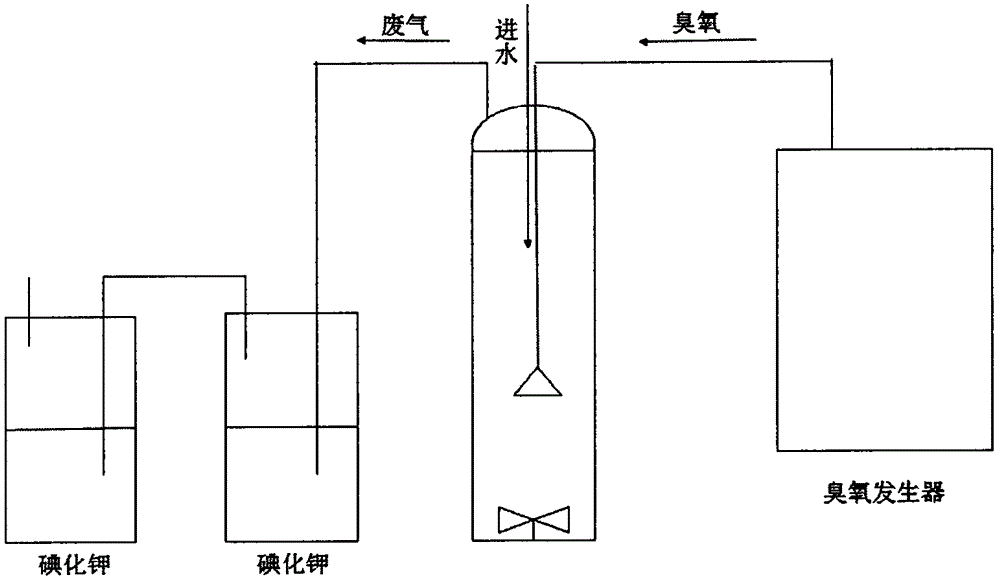

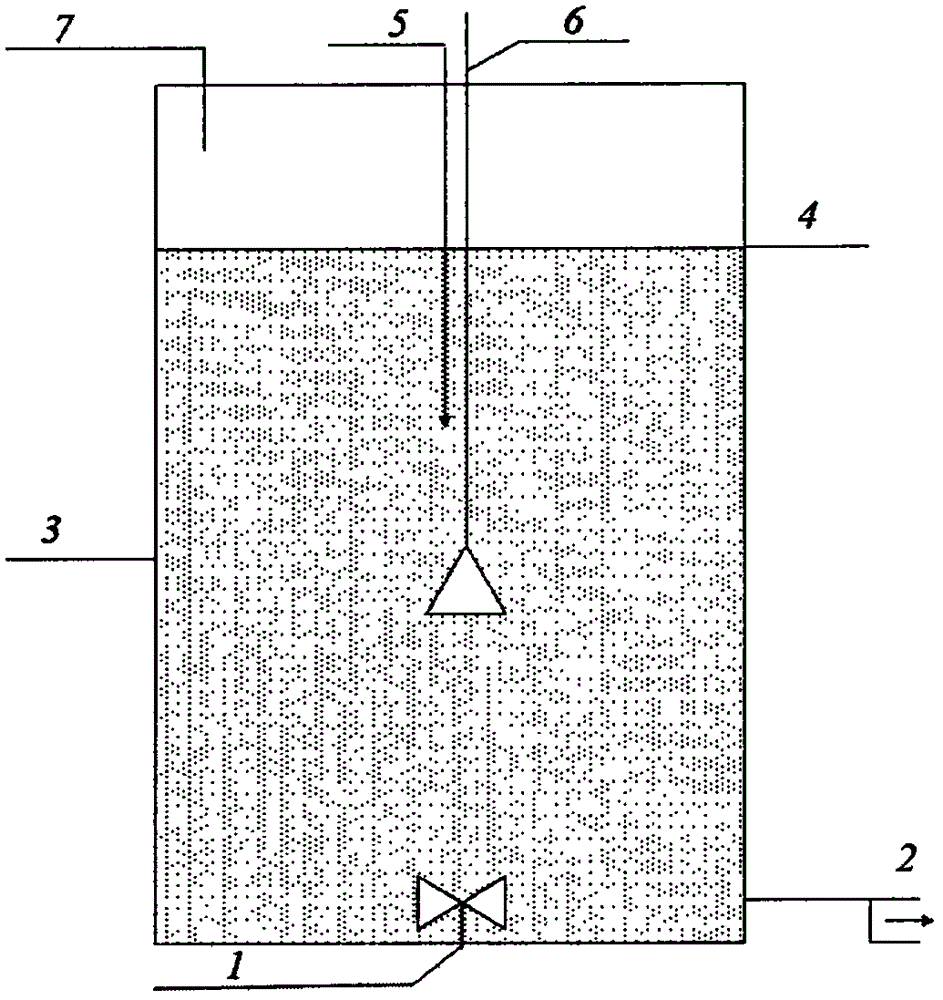

[0017] Specific implementation mode two: Utilize the aqueous solution of amino acid precursors prepared by pure water, pass through the nano-scale Zn-Co-TiO inside 2Ozone contact and catalytic oxidation are carried out in the airtight container of the catalyst at the same time. The ozone enters from the upper part of the container, and a magnetic stirring device is installed at the bottom of the container. During the reaction process, the solution is continuously stirred. The contact time is 6-12 minutes; the tail gas is absorbed with potassium iodide solution. See attached for specific process figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com