Drilling tool assembly and method for well drilling with same

A drilling tool assembly and drill bit technology, which is applied in mines and oil and gas fields, can solve problems affecting drilling efficiency, under pressure, and risk increase, and achieve the effects of simple drilling tool assembly structure, improved cleanliness, and reduced occurrence probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with accompanying drawing.

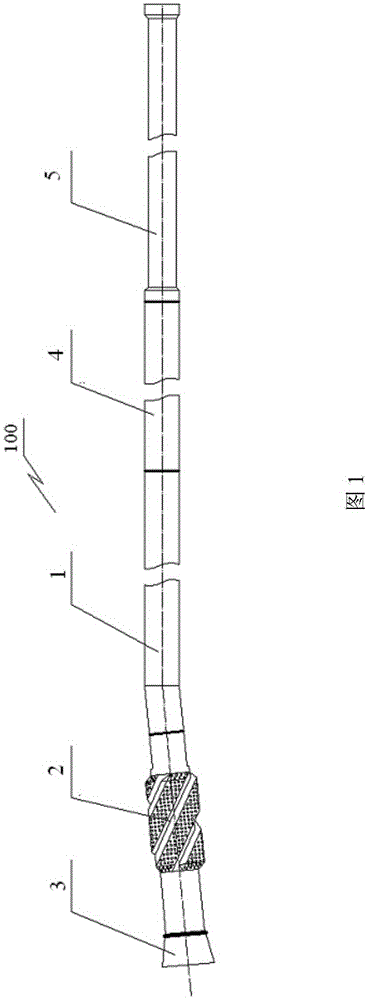

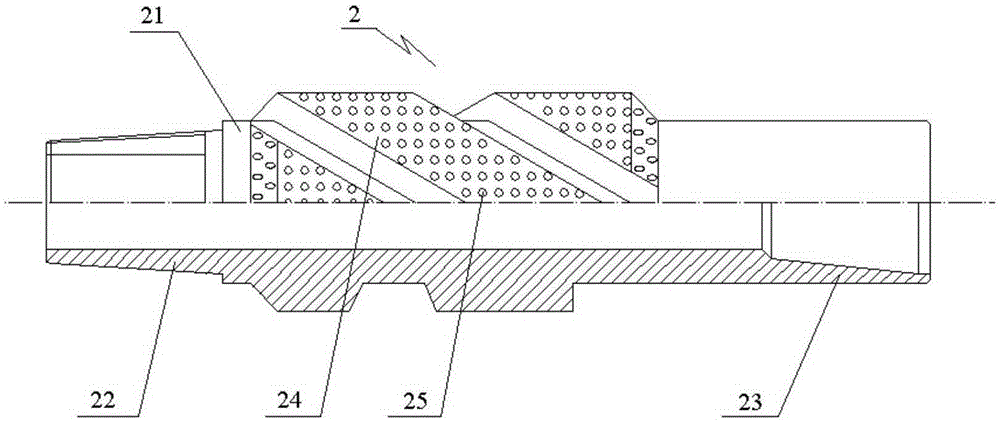

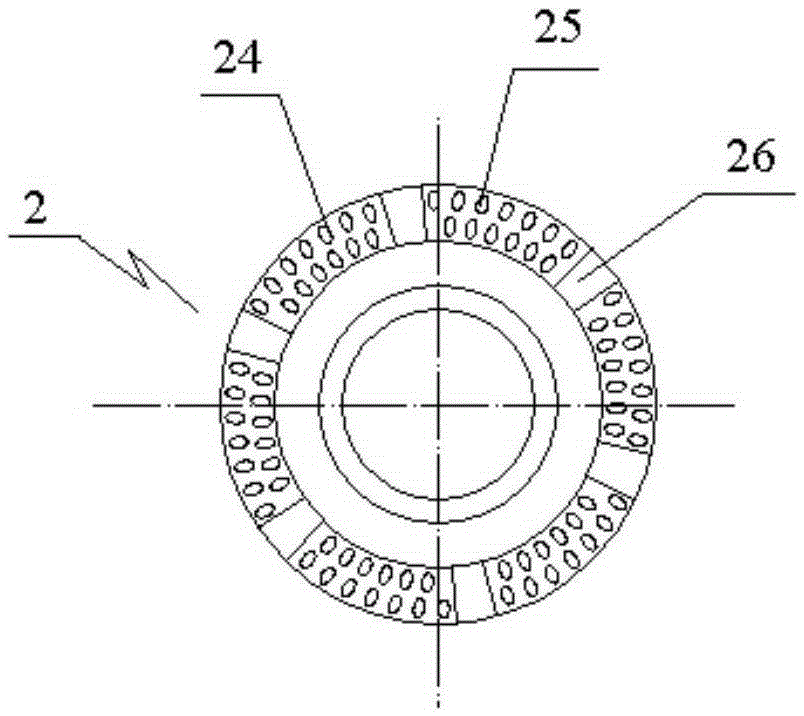

[0037] figure 1 A block diagram of a drill tool assembly 100 according to an embodiment of the present invention is shown in detail. Such as figure 1 As shown, the drilling tool assembly 100 includes a curved screw motor 1 , a centralizer 2 and a drill bit 3 . Wherein, the upper end of the centralizer 2 is fixedly connected with the rotor of the curved screw motor 1, so as to rotate together under the drive of the rotor of the curved screw motor 1, thereby playing the role of repairing the well wall. The upper end of the drill bit 3 is fixedly connected with the lower end of the centralizer 2, so as to follow the rotation of the rotor of the curved screw motor 1, thereby cutting the formation.

[0038] Therefore, by arranging the centralizer 2 on the rotor of the curved screw motor 1, the centralizer 2 can rotate together with the rotor of the curved screw motor 1, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com