Fully automatic liquid sampling device and use method thereof

A liquid sampling, fully automatic technology, applied in sampling devices and other directions, can solve problems such as large errors in density distribution, and achieve stable and reliable performance, convenient disassembly and assembly, and strong adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

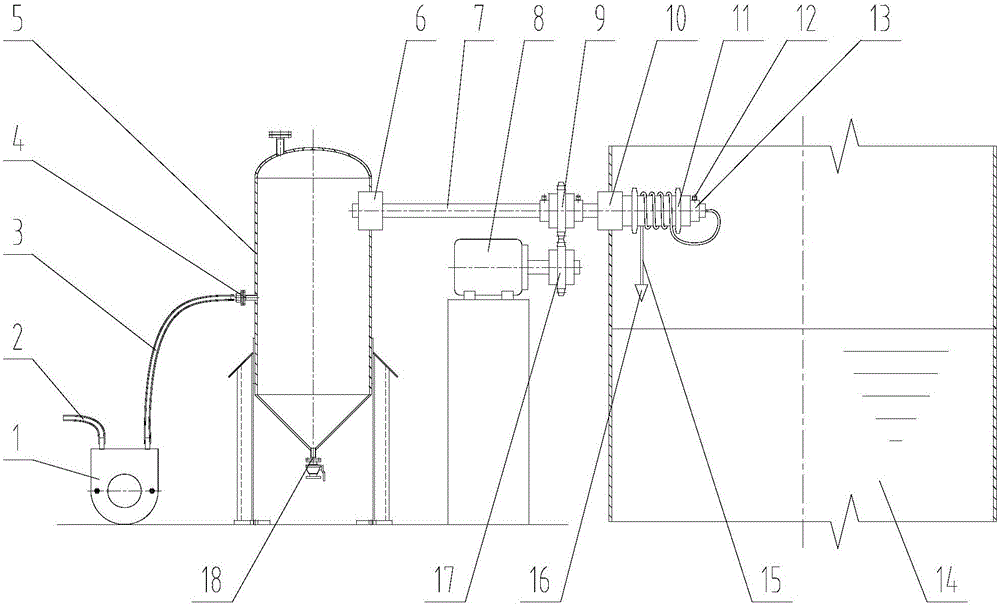

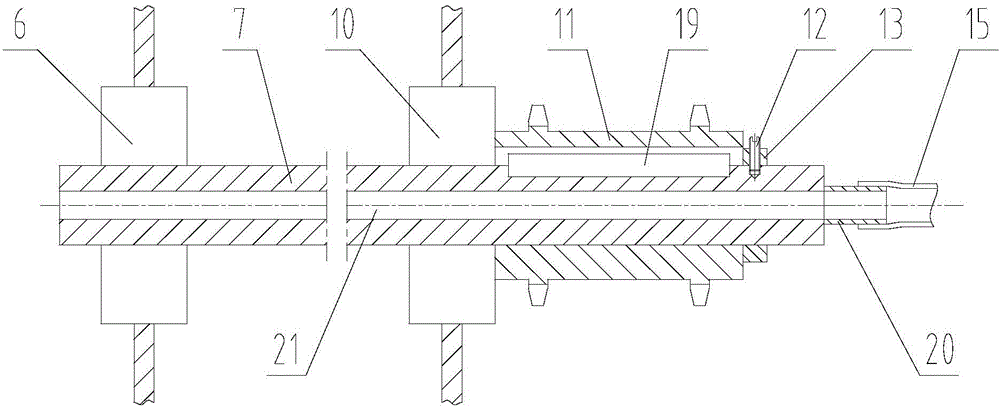

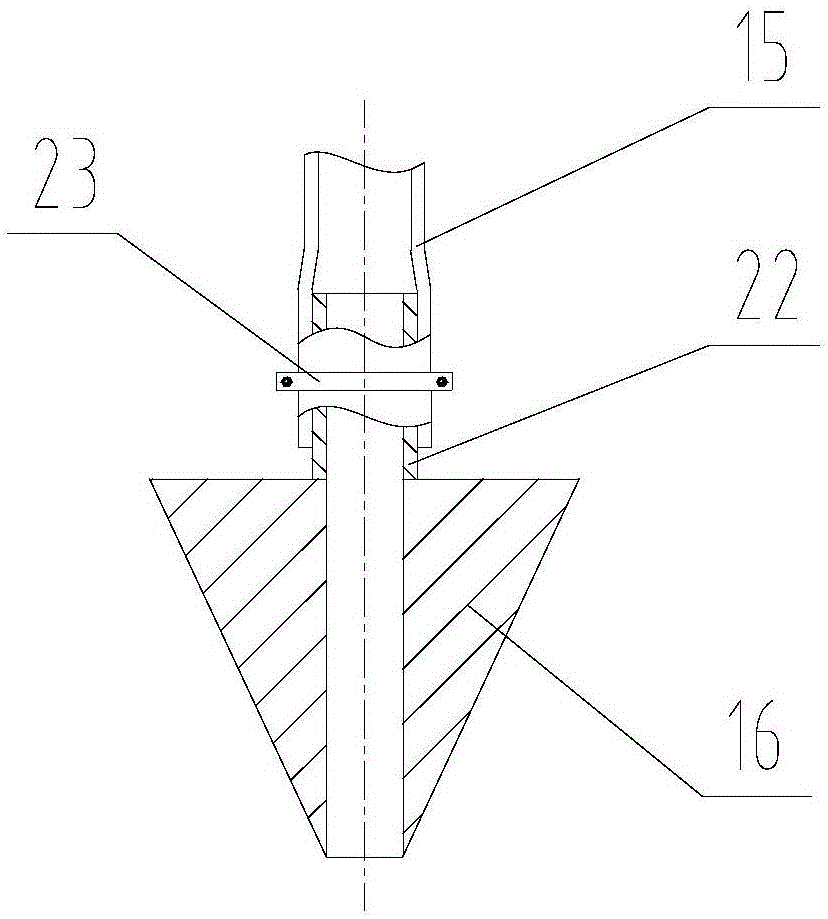

[0034] This embodiment provides a fully automatic liquid sampling device, its structure is as follows figure 1 As shown, it includes peristaltic pump 1, peristaltic pump air pipe one 2, peristaltic pump air pipe two 3, sample storage container air pipe 4, sample storage container 5, mechanical seal device 1 6, through shaft 7, stepping motor 8, driven gear 9. Mechanical seal device 2 10, roller 11, locking screw 12, screw locking retaining ring 13, container 14, suction pipe 15, metal cone hammer 16, driving gear 17, liquid outlet pipe 18 of the sample storage container , key 19, through shaft short connection pipe 20, through shaft sampling through hole 21, conical hammer short connection pipe 22 and throat clamp 23.

[0035] as attached figure 1 As shown, liquid material is housed in the containing container 14, and mechanical sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com