Layered optimization algorithm for solving multi-technical-route workshop scheduling

A job shop, optimization algorithm technology, applied in computing, manufacturing computing systems, instruments, etc., can solve the problems of high complexity of process route selection, increased difficulty in modeling and solving, local optimization of search space, etc. Probability of optimal solution, reduced search and solution time, increased diversity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

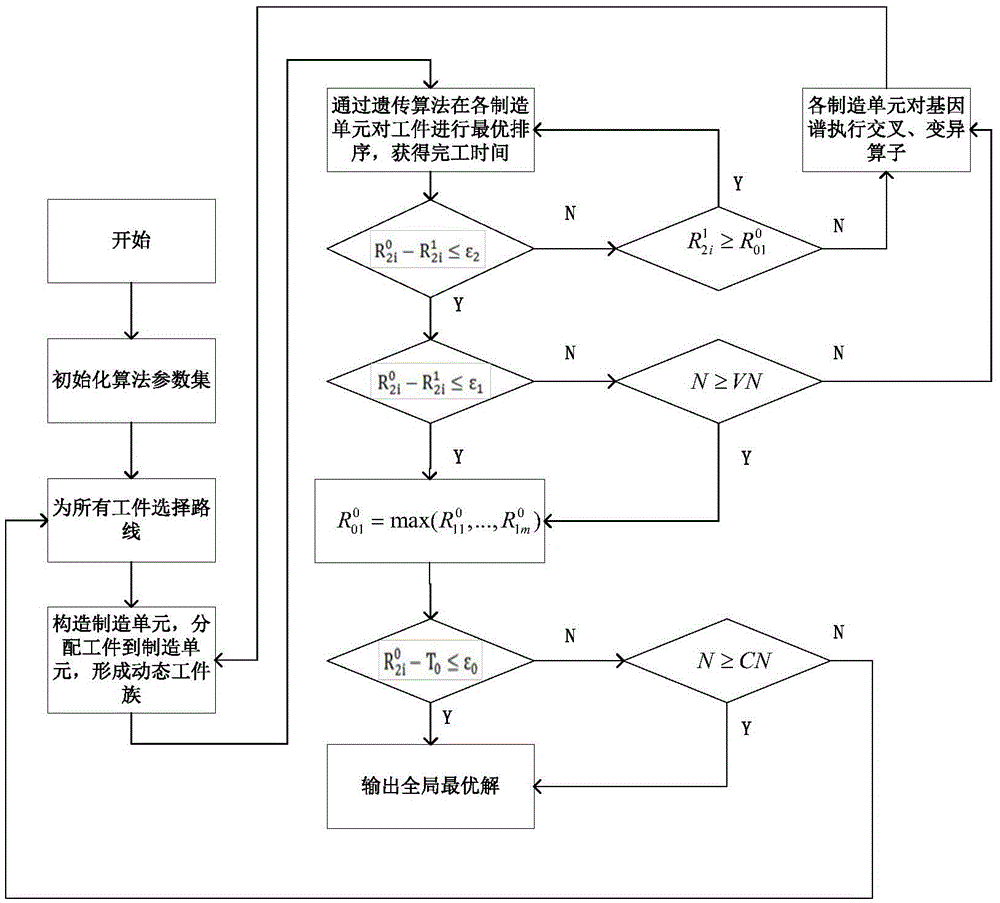

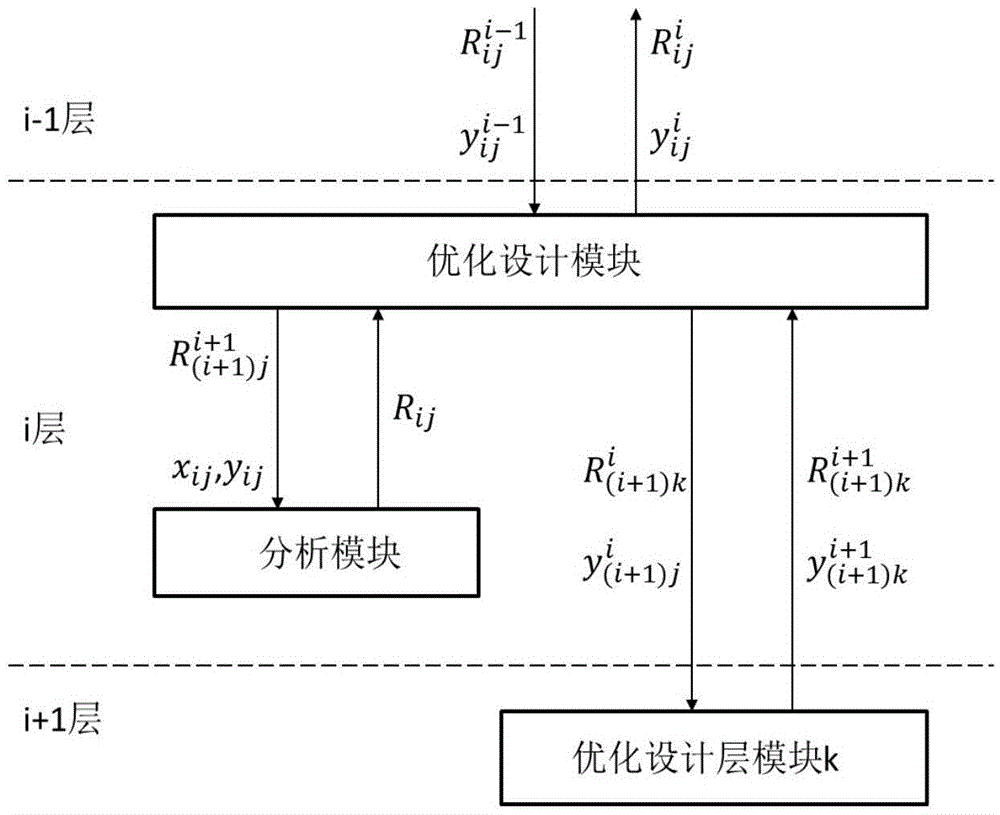

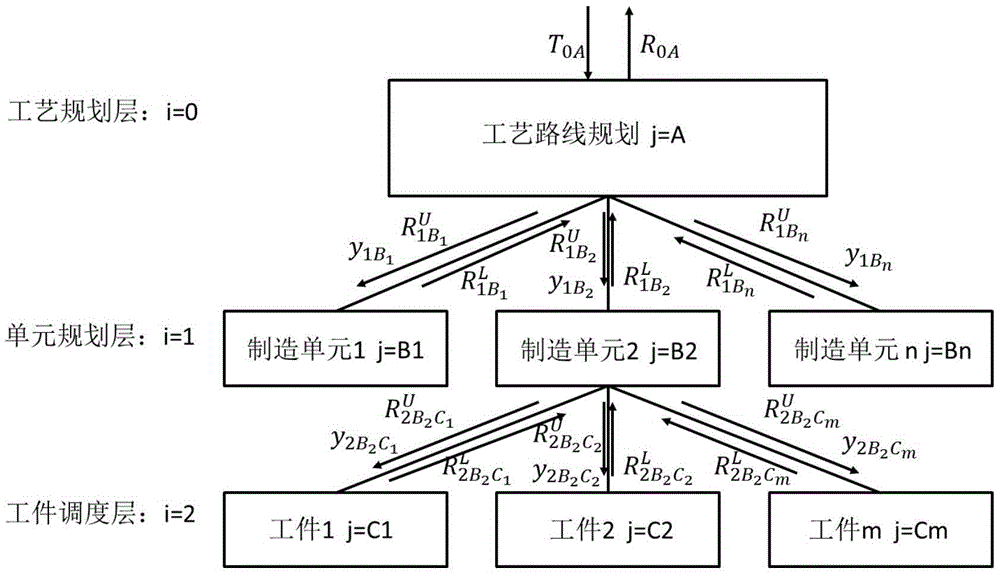

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] Multi-process route job shop scheduling is a production organization form that considers multiple process routes for each workpiece, including the dual optimization tasks of process planning and job shop scheduling, aiming at determining the process route of each workpiece and arranging each The sequence of processes on the machine optimizes the scheduling results. Job shop scheduling with multiple routings is described as follows: n jobs J i (i=1, 2,..., n) workpiece set J; m machines M j (j=1, 2,..., m) machine set M; workpiece J i there is p i optional process routes; there is s on route k ik process; each process O ikl Can be processed on several machines (i=1,2,...,n; k=1,2,...,p i ;l=1,2,...,s ik ). The following assumptions exist:

[0024] (1) A pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com