Improved solving algorithm for flexible flow shop scheduling problem

A flexible flow shop and scheduling problem technology, applied in computing, instruments, data processing applications, etc., to achieve the effects of enhancing global search capabilities, avoiding premature convergence, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

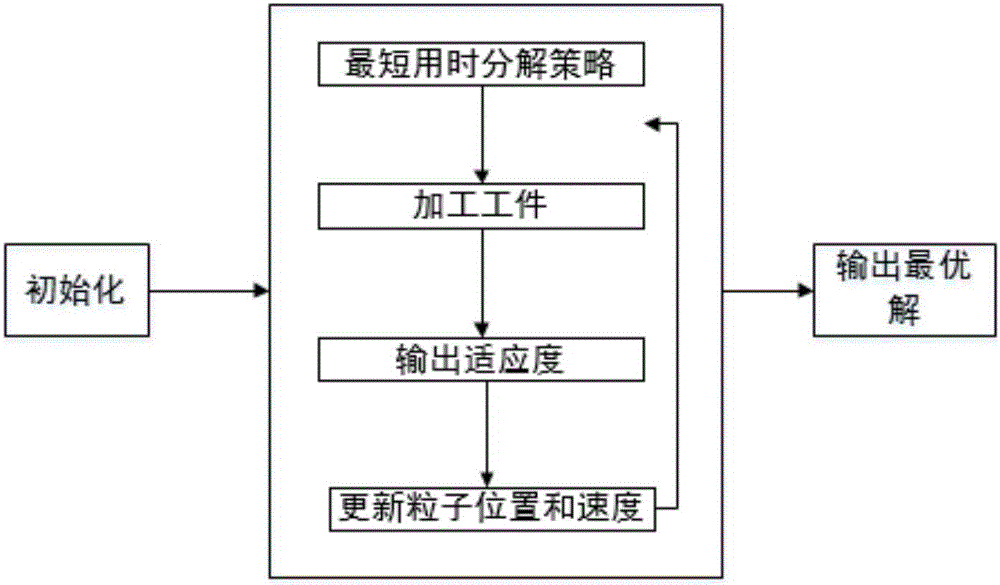

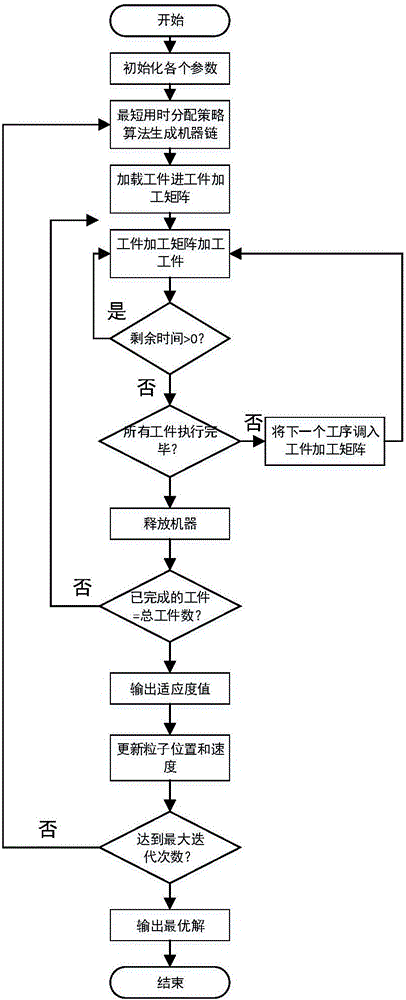

Method used

Image

Examples

Embodiment Construction

[0024] Step 1: FSSP algorithm definition and process, its specific description is as follows:

[0025] Step 1.1) FSSP algorithm definition

[0026] 1) Substitution sequence: the position of the particle is X, and the operation bit of the replacement sequence (i, j) exchanges the i-th element and the j-th element in X.

[0027] 2) Addition operator Add the permutation sequence of the latter velocity to the end of the permutation sequence list of the previous velocity or position. For example: suppose So

[0028] 3) Subtraction operator The subtraction operation is the global optimal solution of the particle minus the particle's individual position or the particle's individual optimal solution position minus the particle's individual position, and the result is a permutation sequence. For example: suppose A=(3,1,2,4,5,6), B=(1,2,4,3,6,5), because A(1)=B(4)=3, the first The exchange sequence is (1,4), that is to say, the first position of the subtraction result is 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com