Priority encoding-based hybrid genetic algorithm for solving job-shop scheduling problem

A hybrid genetic algorithm and job shop technology, applied in the field of computer-executed manufacturing systems, can solve problems such as increased convergence speed and low pheromone convergence speed, so as to enhance performance and avoid excessive execution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

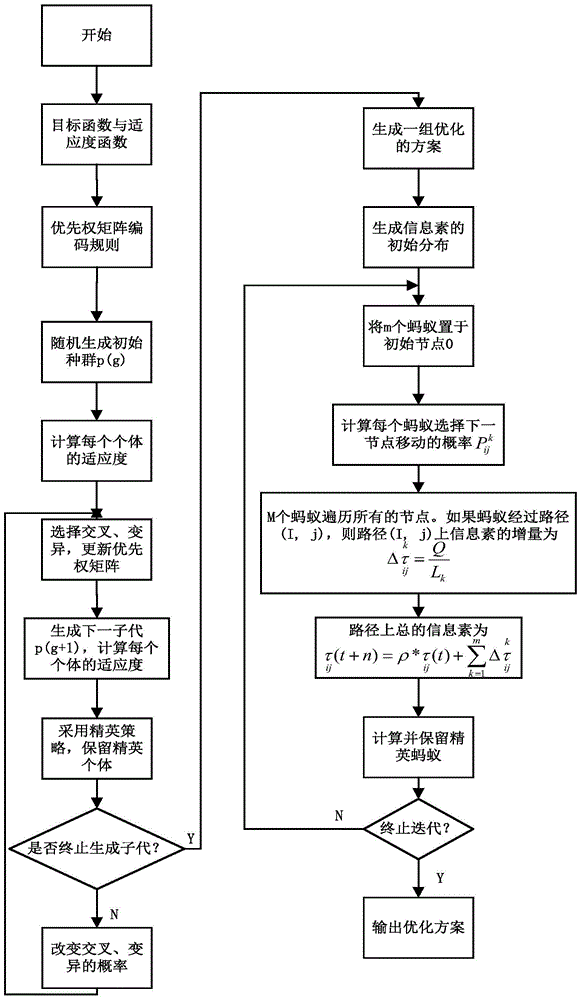

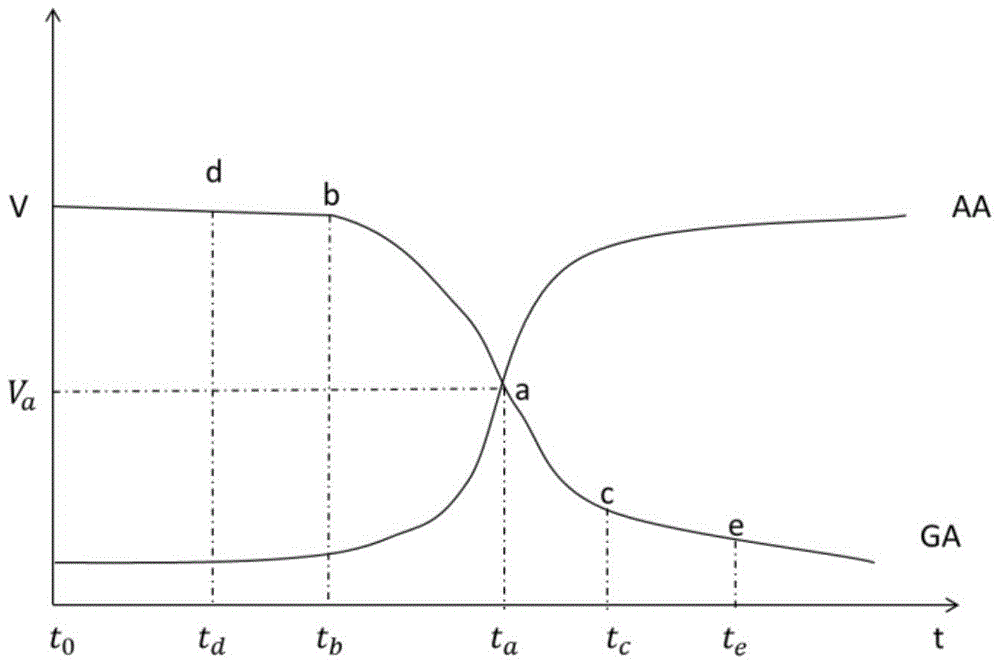

[0022] The invention mixes the self-adaptive genetic algorithm and the improved ant colony algorithm. The invention first utilizes the self-adaptive genetic algorithm to initialize the pheromone distribution, and then executes the improved ant colony algorithm. This algorithm combines the advantages of the two algorithms, avoids the problems of searching for local optimal solutions and long execution time, and overcomes their respective shortcomings. And the performance of the hybrid algorithm is better than that of the previous one, and the performance of the algorithm is better as the size of JSP increases.

[0023] Attached below figure 1 - image 3 and Examples describe the present invention in detail.

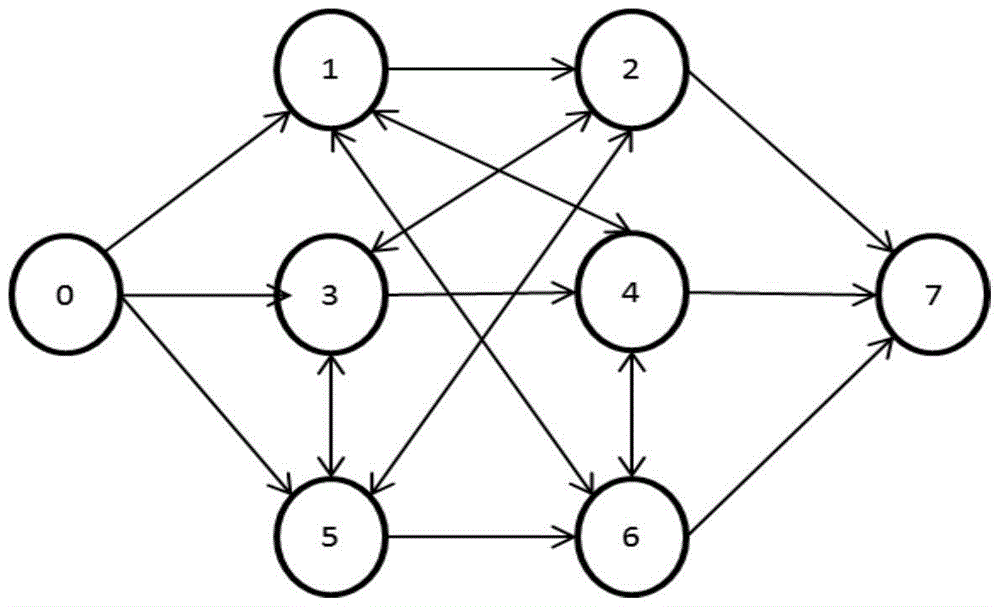

[0024] The job shop scheduling problem refers to the timing distribution problem of assigning n workpieces to m machines for processing. There are many different forms that can be used to describe JSP, such as linear programming model and disjunction graph model. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com