Combined harvester sorting sieve with sieve piece spacing and oblique angle adjustable

A technology of combine harvester and cleaning sieve, applied in agricultural machinery and implements, threshing equipment, application, etc., can solve the problem of inability to realize differential adjustment of screen spacing, inability to realize adjustment of longitudinal spacing of screens, and non-adjustable opening. and other problems, to achieve the effect of small radius of curvature, increased spacing, and difficult to hang grass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

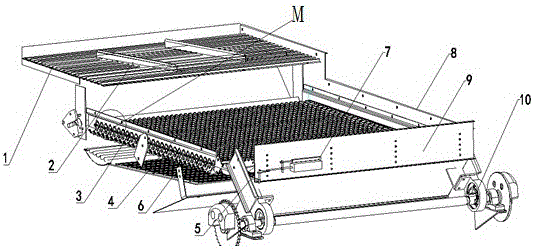

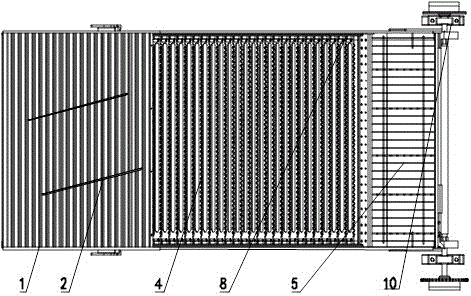

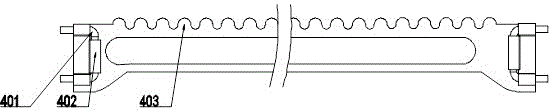

[0021] The specific implementation process of the cleaning screen for a combined harvester with adjustable sieve blade spacing and inclination angle of a specific model of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] Such as figure 1 , as shown in 2, consists of shaking plate 1, deflector plate 2, scissors-type spacing adjustment mechanism 3, wave-shaped sieve sheet 4, zigzag tail sieve 5, lower sieve 6, spacing adjustment drive mechanism 7, cleaning sieve side wall 8 , The tail screen adjusting plate 9 and the eccentric shaking shaft 10 are composed. When the cleaning system is working, the material will fall on the cleaning sieve, and at the same time, the material will fall on the cleaning sieve after being evenly distributed on the shaking plate 1 through the deflector 2; Punching and lower sieve 6; some straw or debris will be blown backward to the zigzag tail sieve 5, the overall distribution of materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com