Preparation method of flavored dried bean curd

A technology of dried tofu and seasoning, which is applied in the field of food manufacturing, can solve problems such as splashing, high microwave heating efficiency, and inability to meet customers' individual taste needs, and achieve the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

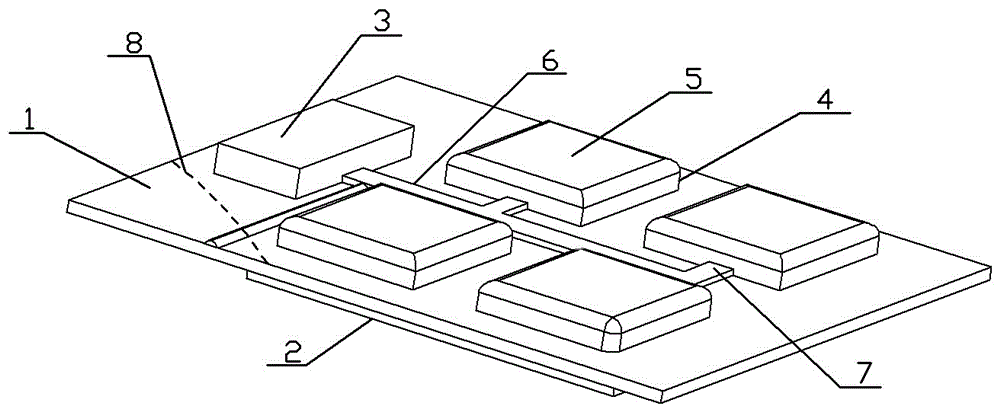

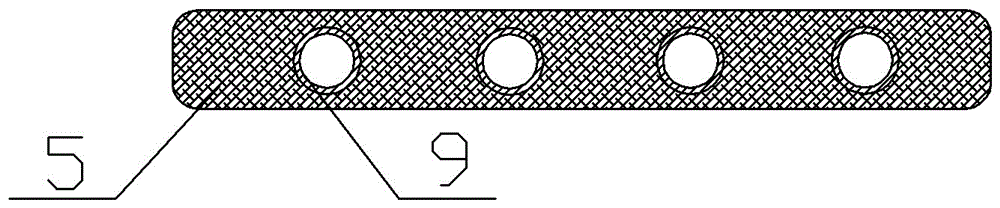

[0021] The reference signs in the drawings of the description include: packaging bag 1, heating bag 2, seasoning chamber 3, dried tofu chamber 4, dried white bean 5, second flow channel 6, first flow channel 7, tear line 8, green pepper Barrel 9.

[0022] Such as figure 1 , figure 2 As shown, the invention discloses a preparation method of seasoned dried tofu, comprising the steps of:

[0023] 1. Raw material preparation: Weigh 1000g of soybeans, wash them, soak them for 24 hours, and prepare several strips of green peppers;

[0024] 2. Grinding and filtering pulp: Grinding soybeans, using a filter screen to filter the pulp to obtain a slag-free soybean milk stock solution;

[0025] 3. Boiling: Boil the soymilk stock solution to 100°C, then cool to 70-80°C;

[0026] 4. Arrange green peppers: put green peppers in a rectangular mold box, arrange several green peppers in parallel, and the distance between adjacent green peppers is 2cm;

[0027] 5. Order bean curd: Slowly po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com