Drying method of carrot powder

A technology of carrot powder and drying method, which is applied in food drying, food science and other directions to achieve the effect of improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

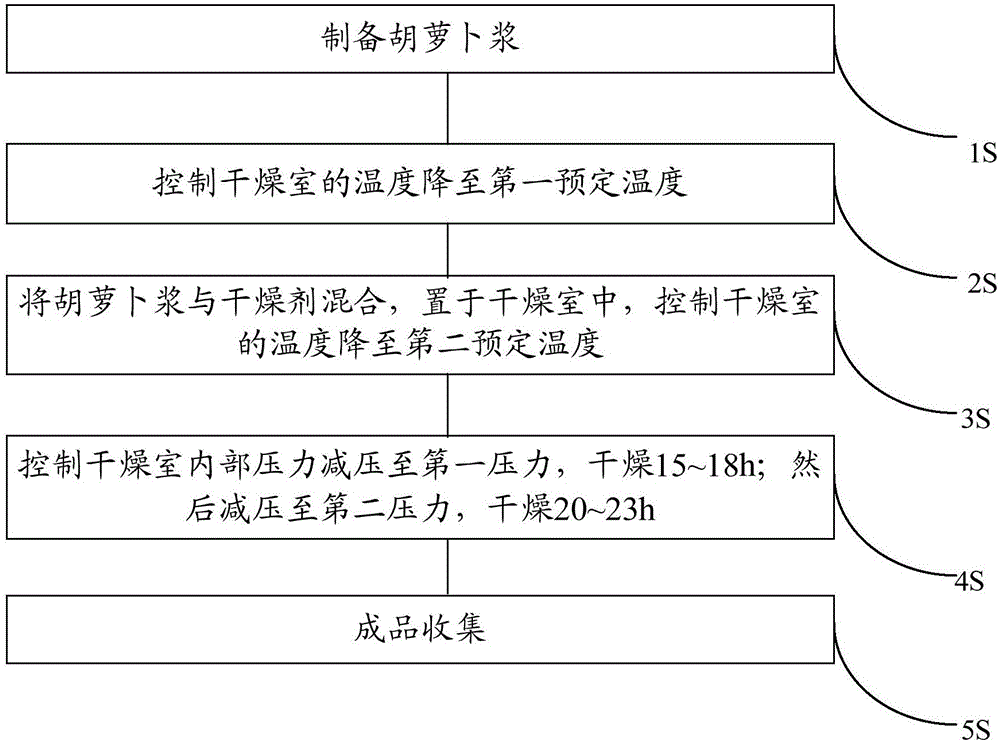

Method used

Image

Examples

Embodiment 1

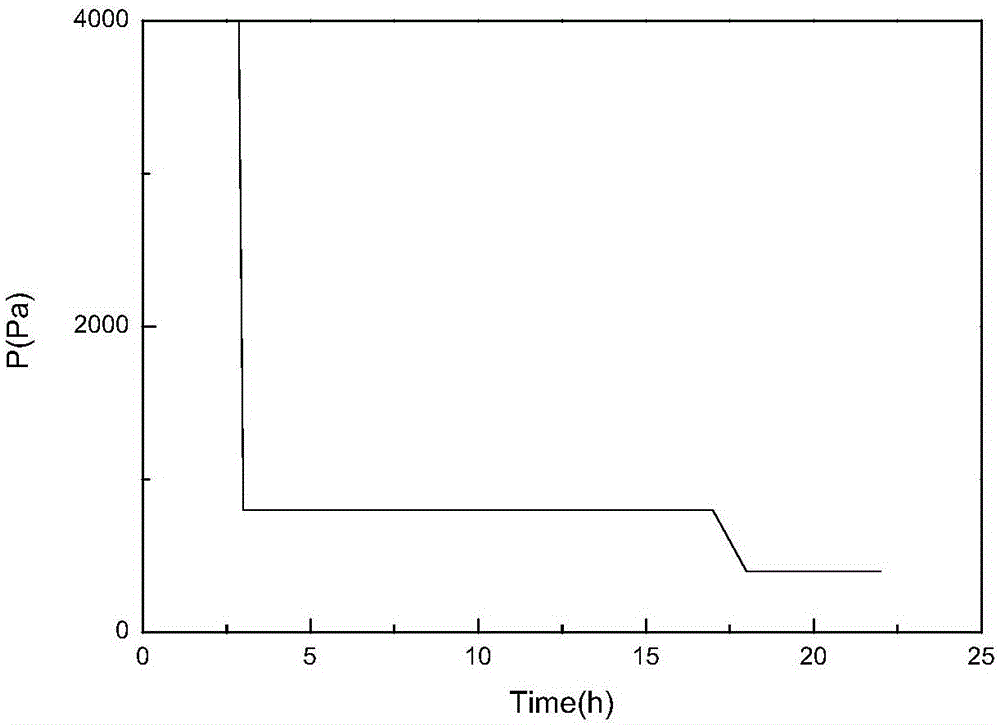

[0036] Select 500g fresh carrots with full rhizomes, orange color, smooth surface, consistent texture and size, wash with water, drain, cut into small pieces, and beat for later use. Control the temperature of the drying room to drop to -10°C, put the carrot pulp and the dried food-grade silica gel desiccant in the drying room, and mix them evenly. The mass ratio of the silica gel desiccant to the carrot pulp is 1:2. Perform liquid nitrogen spraying to cool down, and stop spraying after the temperature in the drying chamber reaches -25°C. Adjust the pressure in the drying chamber to reduce the pressure to 800Pa. During the drying process, measure the water content of the carrot powder, and when the water content of the carrot powder reaches 20% through 17h, adjust the pressure in the drying chamber again, reduce the pressure to 400Pa, continue drying, and when the water content of the carrot powder reaches 8% through 22h, Stop drying and collect the finished carrot powder.

Embodiment 2

[0038] Select 500g fresh carrots with full rhizomes, orange color, smooth surface, consistent texture and size, wash with water, drain, cut into small pieces, and beat for later use. Control the temperature of the drying room to drop to -13°C, put the carrot pulp and the dried food-grade silica gel desiccant in the drying room, and mix them evenly. The mass ratio of the silica gel desiccant to the carrot pulp is 1:2.2. Perform liquid nitrogen spraying to cool down, and stop spraying after the temperature in the drying chamber reaches -28°C. Adjust the pressure in the drying chamber to reduce the pressure to 850Pa. During the drying process, measure the water content of the carrot powder. When the water content of the carrot powder reaches 20% after 16.5 hours, adjust the pressure in the drying chamber again, reduce the pressure to 400Pa, and continue drying. After 22 hours, the water content of the carrot powder reaches 8%. , stop drying, and collect the finished carrot powde...

Embodiment 3

[0040] Select 500g fresh carrots with full rhizomes, orange color, smooth surface, consistent texture and size, wash with water, drain, cut into small pieces, and beat for later use. Control the temperature of the drying room to drop to -15°C, place the carrot pulp and the dried food-grade silica gel desiccant in the drying room, and mix them evenly. The mass ratio of the silica gel desiccant to the carrot pulp is 1:2.5. Perform liquid nitrogen spraying to cool down, and stop spraying after the temperature in the drying chamber reaches -30°C. Adjust the pressure in the drying chamber to reduce the pressure to 900Pa. During the drying process, measure the water content of the carrot powder. After 15.5 hours, when the water content of the carrot powder reaches 20%, adjust the pressure in the drying chamber again, reduce the pressure to 400 Pa, and continue drying. After 21 hours, the water content of the carrot powder reaches 8%. , stop drying, and collect the finished carrot p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com