Diamond with 81 cutting surfaces

A facet, diamond technology applied to 81 facet diamonds. It can solve the problems of less refraction, dim fire and flicker, and rough waist, and achieve the effect of high refraction and high fire and flicker.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

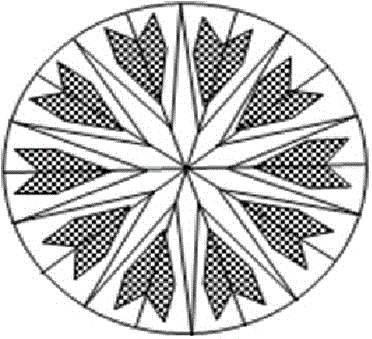

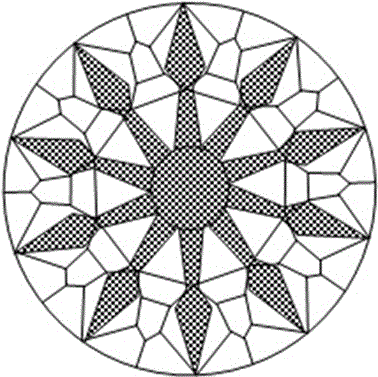

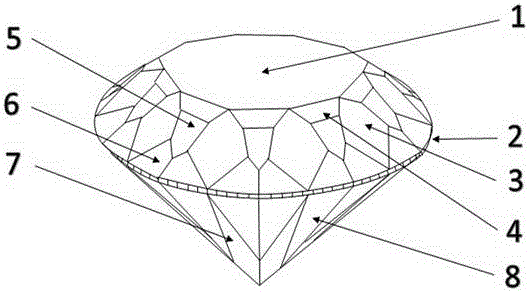

[0028] See figure 1 —— Figure 7 , the diamond with 81 facets of the present invention comprises: a crown, a pavilion and a girdle 2 connecting the crown and the pavilion, the number of the crown facets is 51, the number of the pavilion facets is 30, and the girdle 2 is circular The number of auxiliary small facets is 65-100, a total of 81 main facets and 65-100 auxiliary small facets.

[0029] The crown has a symmetrical structure: the top of the crown has a table top 1, the side of the crown has 10 crown hexagonal main cutting surfaces 3, 10 crown trapezoidal main cutting surfaces 4, 10 crown shield-shaped main cutting surfaces 5 and 20 quadrilateral main cutting surfaces 6 on the upper waist of the crown.

[0030] See figure 1 , Figure 7 , the two vertices of the crown hexagonal main cutting surface 3 are respectively located on the table 1 and the waist 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com