A carbon fiber and polyetheretherketone composite bone plate and preparation method thereof

A polyetheretherketone and bone plate technology, which is used in surgery, coating, medical science and other directions, can solve the problems of carbon fiber reinforcement not fully functioning, modulus mismatching with natural bone, hidden dangers of biological toxicity, etc., and achieve good results. X-ray penetration, improved biosafety, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

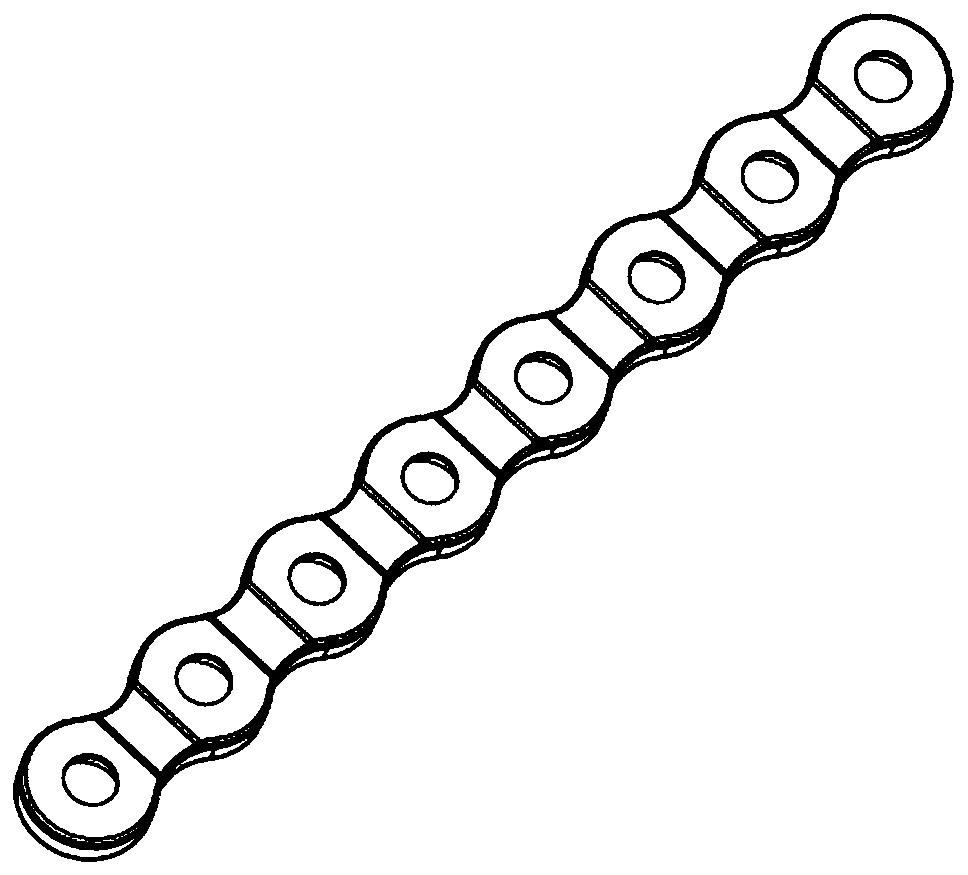

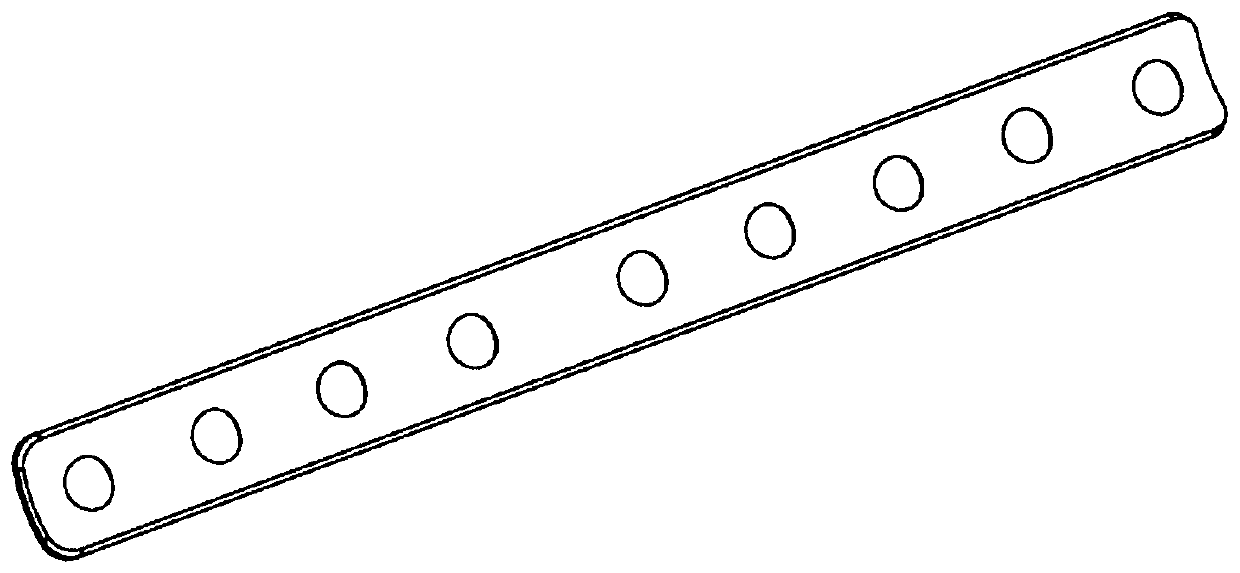

Image

Examples

Embodiment 1

[0052] Example 1: Preparation of carbon fiber and polyether ether ketone composite bone plate

[0053] Proceed as follows:

[0054] 1. Preparation of composite block materials of polyetheretherketone (PEEK) and carbon fiber cloth;

[0055] 1.1 Cut the appropriate carbon fiber cloth size according to the shape of the block mold, and electrostatically spray PEEK on the single-layer carbon fiber cloth. The form of carbon fiber cloth can be unidirectional carbon fiber cloth or woven carbon fiber cloth; the woven carbon fiber cloth can be 1K Or 3K structure; among them, PEEK can be amorphous or crystalline, and the particle size distribution range is 10-200 μm; further, the weight ratio of PEEK and CF is 1:0.2; further, the parameters of electrostatic spraying are as follows: the processing temperature range is 380 -400℃, treatment time 3-30min, can be repeated many times until the designed weight ratio is reached;

[0056] 1.2 Place the single-layer carbon fiber cloth sprayed wi...

Embodiment 2

[0066] Example 2: Preparation of carbon fiber and polyether ether ketone composite bone plate

[0067] Proceed as follows:

[0068] 1. Preparation of composite block materials of polyetheretherketone (PEEK) and carbon fiber (CF);

[0069] 1.1 Cut the appropriate CF size according to the shape of the block mold, and electrostatically spray PEEK on the single-layer CF. The form of CF can be unidirectional carbon fiber cloth or woven carbon fiber cloth; the woven carbon fiber cloth can be 1K or 3K structure ; Among them, PEEK can be amorphous or crystalline, and the particle size distribution range is 10-200 μm; further, the weight ratio of PEEK and CF is 1: 4; further, the parameters of electrostatic spraying are as follows: the processing temperature range is 380-400 ° C , the processing time is 3-30min, which can be repeated many times until the designed weight ratio is reached;

[0070] 1.2 Place the CF single-layer cloth sprayed with PEEK layer by layer in the mold, the sp...

Embodiment 3

[0080] Example 3: Preparation of carbon fiber and polyether ether ketone composite bone plate

[0081] Proceed as follows:

[0082] 1. Preparation of composite block materials of polyetheretherketone (PEEK) and carbon fiber (CF);

[0083] 1.1 Cut the appropriate CF size according to the shape of the block mold, and electrostatically spray PEEK on the single-layer CF. The form of CF can be unidirectional carbon fiber cloth or woven carbon fiber cloth; the woven carbon fiber cloth can be 1K or 3K structure ; Among them, PEEK can be amorphous or crystalline, and the particle size distribution range is 10-200 μm; further, the weight ratio of PEEK and CF is 1:1; further, the parameters of electrostatic spraying are as follows: the processing temperature range is 380-400 ° C , the processing time is 3-30min, which can be repeated many times until the designed weight ratio is reached;

[0084]1.2 Place the CF single-layer cloth sprayed with PEEK layer by layer in the mold, the spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com