Preparation and application of a molybdenum sulfide-ferric oxide composite nano-antibacterial material

A technology of ferroferric oxide and antibacterial materials, applied in application, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high cost, environmental hazards, low efficiency, etc., and achieve low cost and high removal rate , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

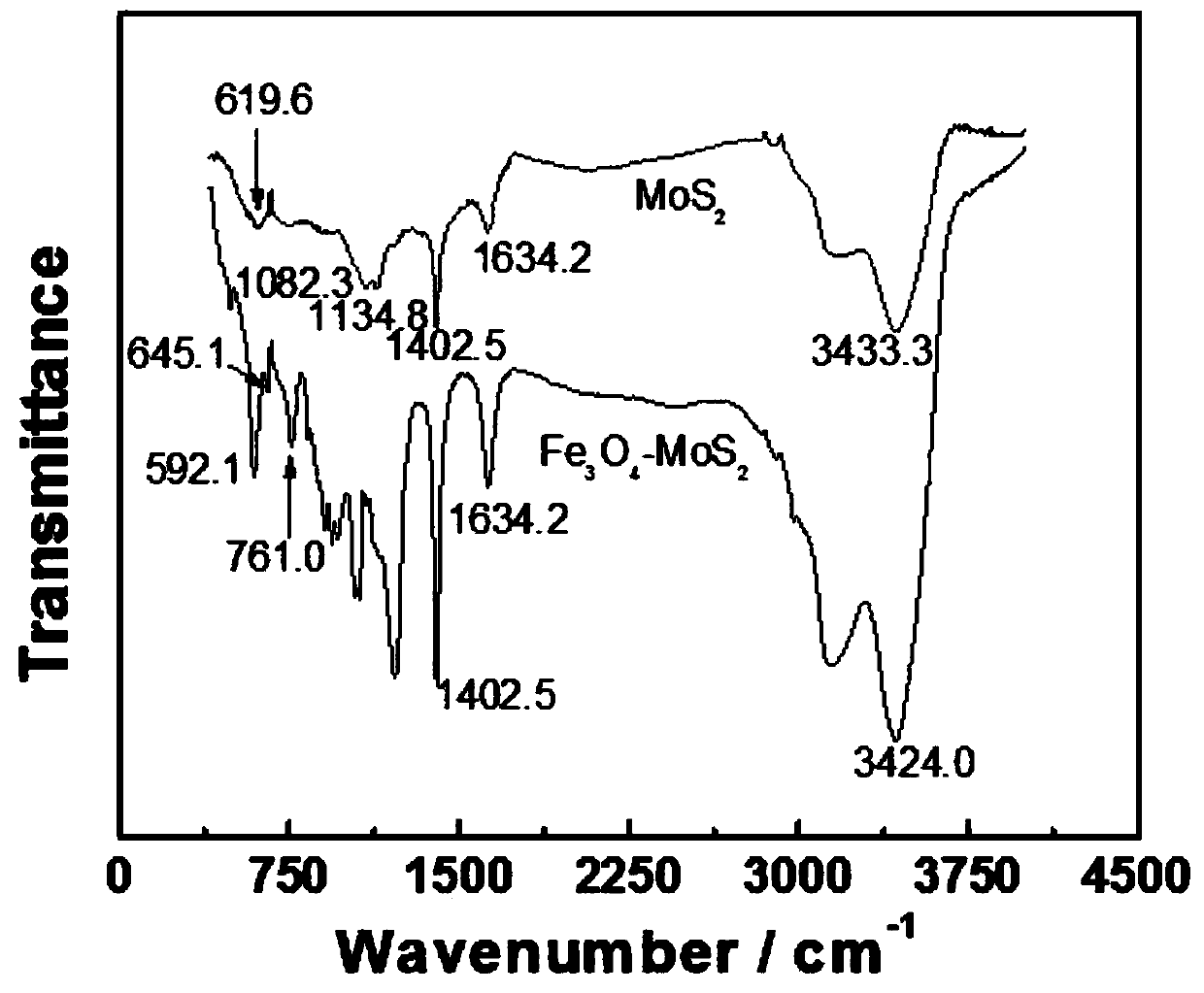

[0038] The preparation and application of a kind of molybdenum sulfide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0039] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 carry out deoxygenation;

[0040] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and stir vigorously for 5 min, then add NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C;

[0041] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0042] (4) Weigh 1 mmol of sodium molybdate dihydrate, 5 mmol of thioacetamide and 0.5 g of the product of step (3...

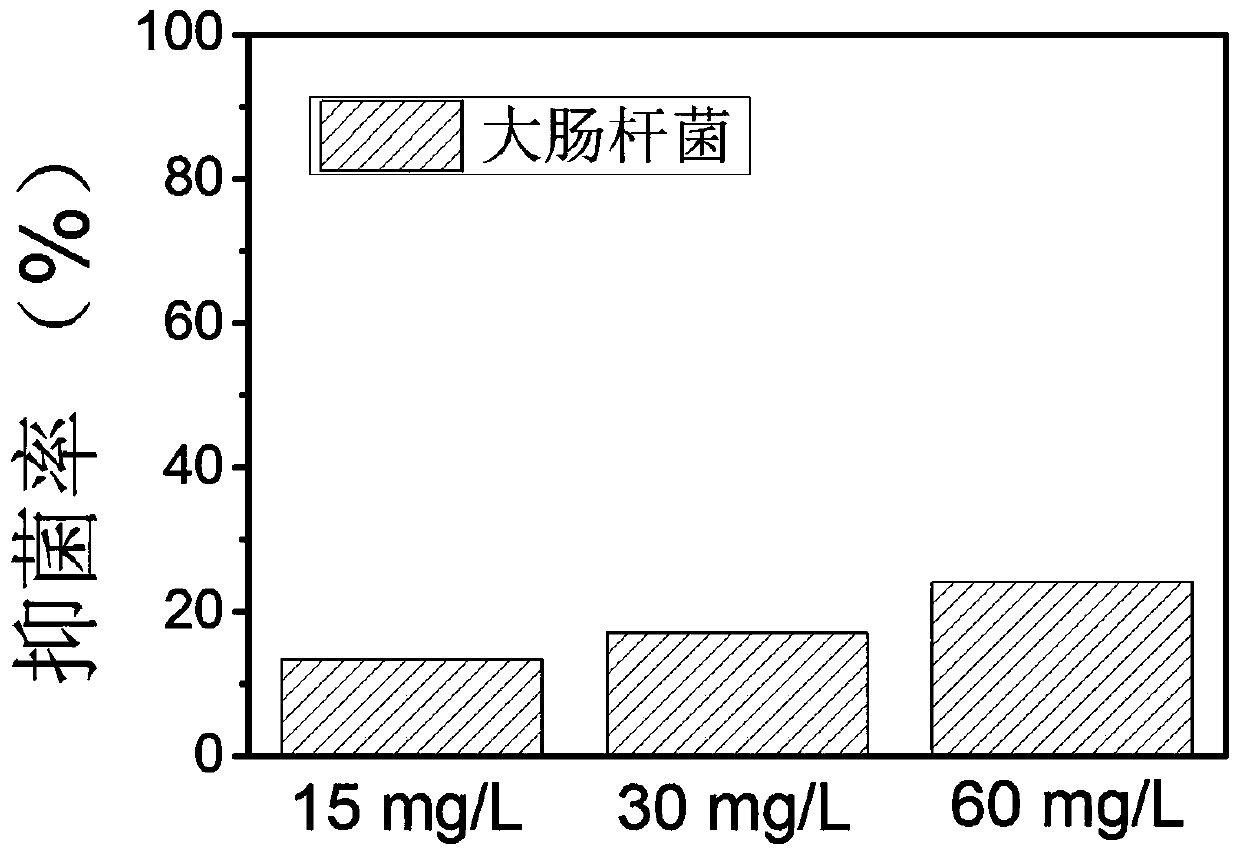

Embodiment 2

[0052] The preparation and application of a kind of molybdenum sulfide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0053] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 carry out deoxygenation;

[0054] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and stir vigorously for 5 min, then add NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C;

[0055] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0056] (4) Weigh 1 mmol of sodium molybdate dihydrate, 5 mmol of thioacetamide and 0.5 g of the product of step (3...

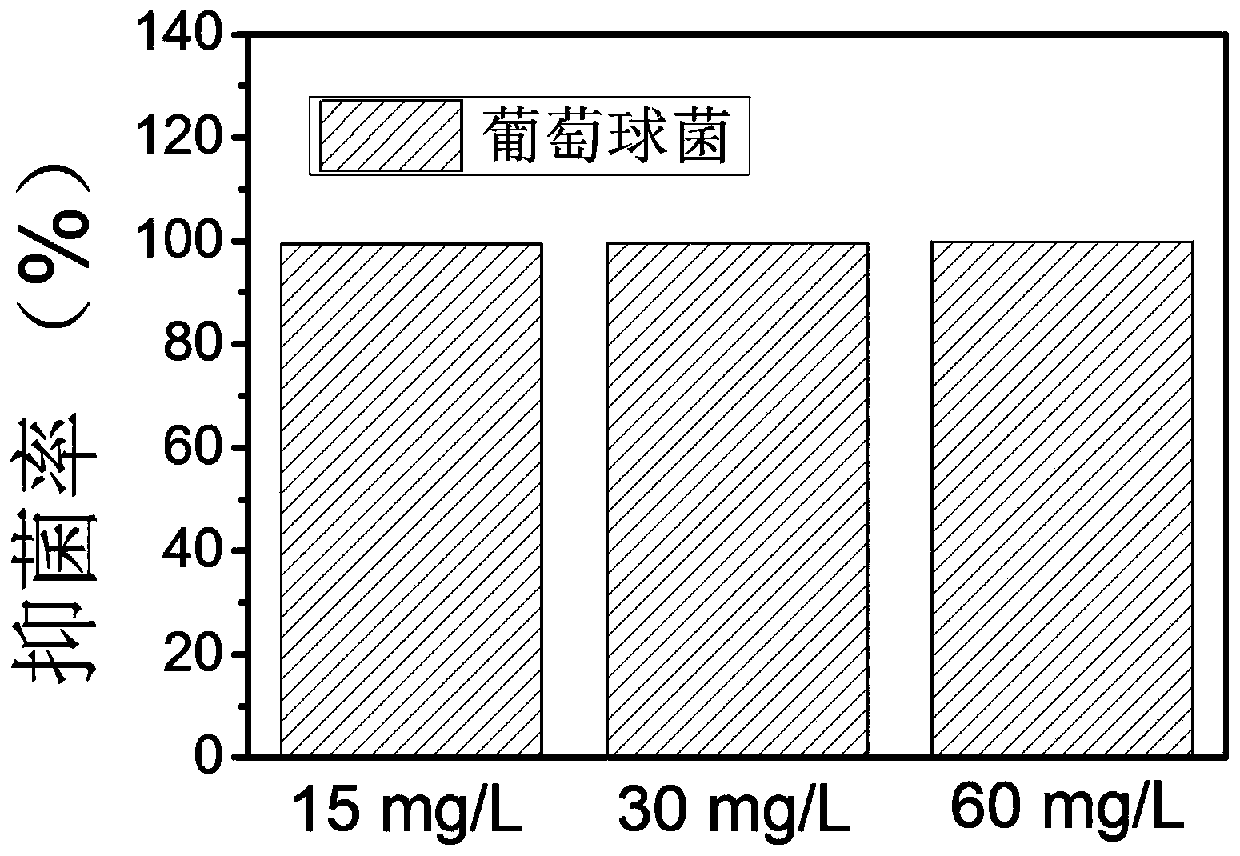

Embodiment 3

[0066] The preparation and application of a kind of molybdenum sulfide-ferric oxide composite nano antibacterial material of the present invention, comprises the following steps successively:

[0067] (1) Dissolve ferric chloride hexahydrate and ferrous dichloride tetrahydrate in deionized water at a molar ratio of Fe(III):Fe(II) of 2:1, and blow N into the solution. 2 carry out deoxygenation;

[0068] (2) Put the solution in a water bath at 60°C and keep N 2 Protect and stir vigorously for 5 min, then add NH 4 OH solution was slowly added to the solution until the pH was 8, then the solution was mixed and aged at 60°C;

[0069] (3) The precipitate in the solution is separated by an external magnetic force, and the supernatant is poured out. The precipitate was washed 4 times with deionized water, and then dried overnight at 40°C to obtain nano-ferric oxide;

[0070] (4) Weigh 1 mmol of sodium molybdate dihydrate, 5 mmol of thioacetamide and 0.5 g of the product of step (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com