High-In-composition InGaN/GaN quantum well structure solar cell based on self-supporting GaN substrate and preparation method thereof

A solar cell, self-supporting technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high defect density, high In composition and high quality, and it is difficult to obtain high-quality high In composition InGaN thin films, etc. Efficiency, the effect of expanding the light absorption range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

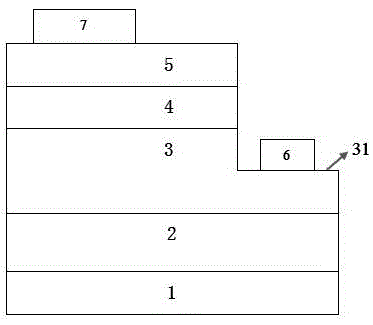

[0034] A self-supporting GaN substrate 1, the substrate is gallium nitride material, the size of the gallium nitride self-supporting wafer used is 20.0mm×20.5mm (±0.2mm), the thickness is 350±25μm, and the crystal orientation It is C-plane(0001)±1 0 , TTV≤15μm, bending degree BOW≤20μm, conductivity type is N type, resistivity 5 cm -2 , effective area>90%. The use of gallium nitride substrates can reduce the lattice mismatch and thermal mismatch between the substrate and the epitaxial layer.

[0035] A GaN buffer layer 2, the gallium nitride buffer layer is fabricated on the self-supporting GaN substrate 1, the GaN buffer layer is grown by RF-MBE method, the growth temperature is 500°C, the thickness is 20nm, the gallium nitride buffer layer Layer 2 provides nucleation centers for the subsequent growth of n-type doped GaN layer materials.

[0036] An n-type doped GaN layer 3, the n-type doped GaN layer 3 is fabricated on the gallium nitride buffer layer 2, and the doped GaN ...

Embodiment 2

[0043] A self-supporting GaN substrate 1, the substrate is gallium nitride material, the size of the gallium nitride self-supporting wafer used is 20.0mm×20.5mm (±0.2mm), the thickness is 350±25μm, and the crystal orientation is C-plane(0001)±1 0 , TTV≤15μm, bending degree BOW≤20μm, conductivity type is N type, resistivity 5 cm -2 , effective area>90%. The use of gallium nitride substrates can reduce the lattice mismatch and thermal mismatch between the substrate and the epitaxial layer.

[0044] A GaN buffer layer 2, the gallium nitride buffer layer is fabricated on the self-supporting GaN substrate 1, the GaN buffer layer is grown by RF-MBE method, the growth temperature is 500°C, the thickness is 15nm, the gallium nitride buffer layer Layer 2 provides nucleation centers for the subsequent growth of n-type doped GaN layer materials.

[0045] An n-type doped GaN layer 3, the n-type doped GaN layer 3 is fabricated on the gallium nitride buffer layer 2, and the doped GaN buf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Growth thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com