Machining method for continuously generating non-circular gear into gear shaping

A technology of non-circular gears and processing methods, which is applied to components with teeth, belts/chains/gears, gear teeth, etc., which can solve the problems of processing principle errors, redundant codes, and restrictions on the feed speed of each axis of the machine tool, and achieve The effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

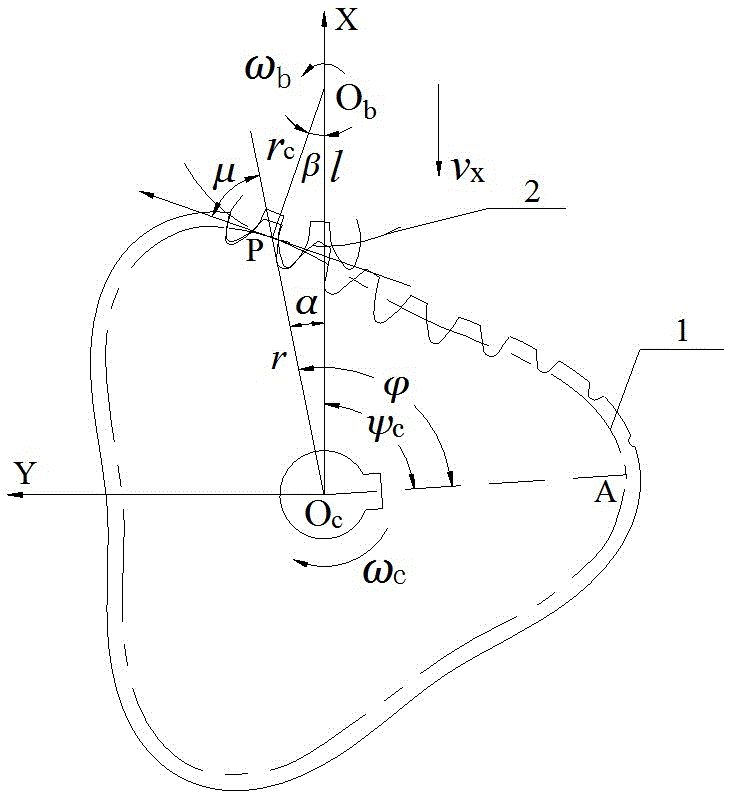

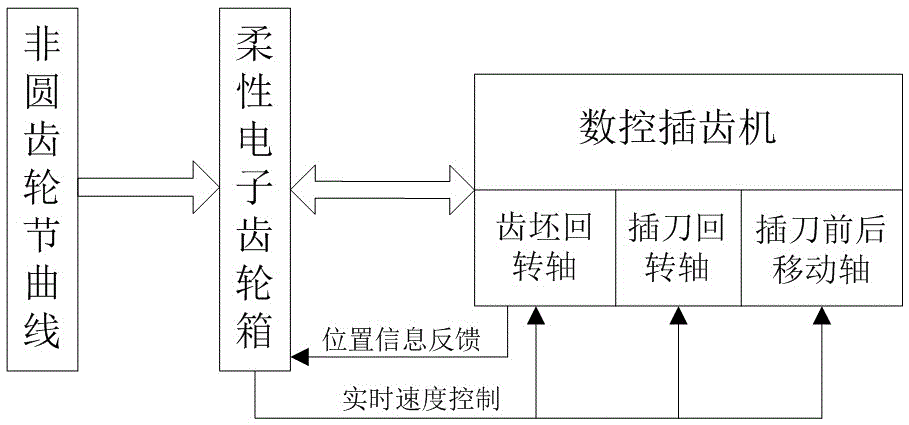

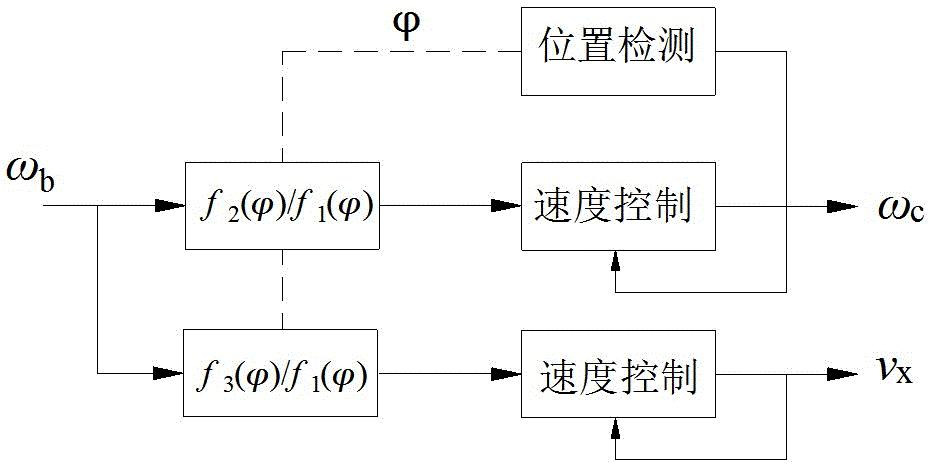

[0088] see Figure 4 , in order to adopt the method of the present invention, inserting the external meshing fifth-order elliptic spur gear with the constant speed of the rotary shaft of the inserting tool to insert the cross-sectional view of the tool position track, the external meshing fifth-order elliptic spur gear pitch curve equation is,

[0089]

[0090] The workpiece to be processed is an external meshing fifth-order elliptical spur gear, and the gear parameters related to processing: semi-major axis A=108.201mm, order n=5, tooth width b=50mm, eccentricity k=0.04, normal modulus m n =4mm, number of gear teeth Z=55, polar angle The determination of processing technology parameters can be selected with reference to the processing of cylindrical gears. Here, it is taken as: the number of teeth of the slotting tool z=18, the number of strokes of the vertical moving axis of the slotting tool is 200 times / min, the radial speed is 1mm / min, and the rotation speed of the s...

Embodiment 2

[0099] see Figure 6 , in order to adopt the method of the present invention, inserting the external meshing six-order elliptic helical gear tool position track sectional view with the constant speed of the inserting tool rotary shaft, the external meshing six-order elliptic helical gear pitch curve equation is the same as formula (12), which is related to processing Gear parameters: semi-major axis A=131.830mm, order n=6, tooth width b=50mm, eccentricity k=0.05, normal modulus m n =4mm, number of gear teeth Z=65, polar angle The rotation direction of the gear is right-handed, and the helix angle is 15 o . The determination of processing technology parameters can be selected with reference to the processing of cylindrical gears. Here, it is taken as: the number of teeth of the slotting tool z=18, the number of strokes of the vertical moving axis of the slotting tool is 200 times / min, the radial speed is 1mm / min, and the rotation speed of the slotting tool is 30° / min. min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com