Novel weld preheating device

A new type of preheating technology before welding, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high maintenance cost, high energy consumption, complex structure, etc., to meet the requirements of solving flame properties and prevent tempering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

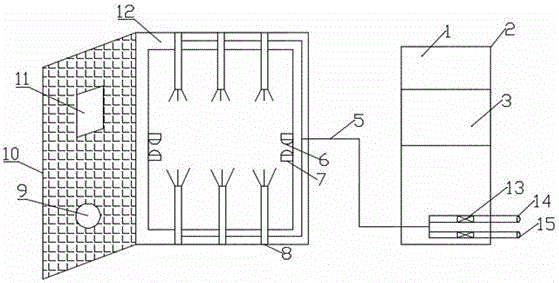

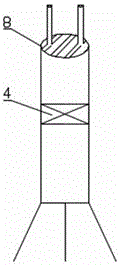

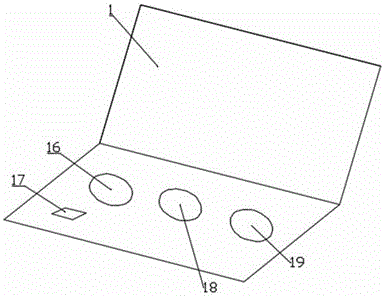

[0019] see figure 1 , figure 2 with image 3 A new type of pre-welding preheating device, including a box body 12 and a control cabinet 2. Since the length, width and height of the box body 12 are 2000*1500*1000MM, it is ensured that common plates can be placed in the box body 12. There are multiple flame heaters 8 and card slots 7 inside, and the flame heaters 8 are respectively arranged in the box body 12. At the same time, the flame heaters 8 are arranged symmetrically up and down in the box body 12, which ensures that the plate is heated evenly when heated. The card slot 7 is symmetrically arranged left and right in the box body 12, which is convenient for the plate to be easily put into the card slot 7, and is not easy to slip, reducing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length, width and height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com