Automatic welding device for optical cable longitudinally wrapped steel belt or aluminum belt connection

A technology of automatic welding and welding devices, which is applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of affecting production and continuous operations, not improving production efficiency, wasting raw materials, etc., to improve the quality of optical cables and equipment production capacity , Reduce the cost of raw materials and save labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

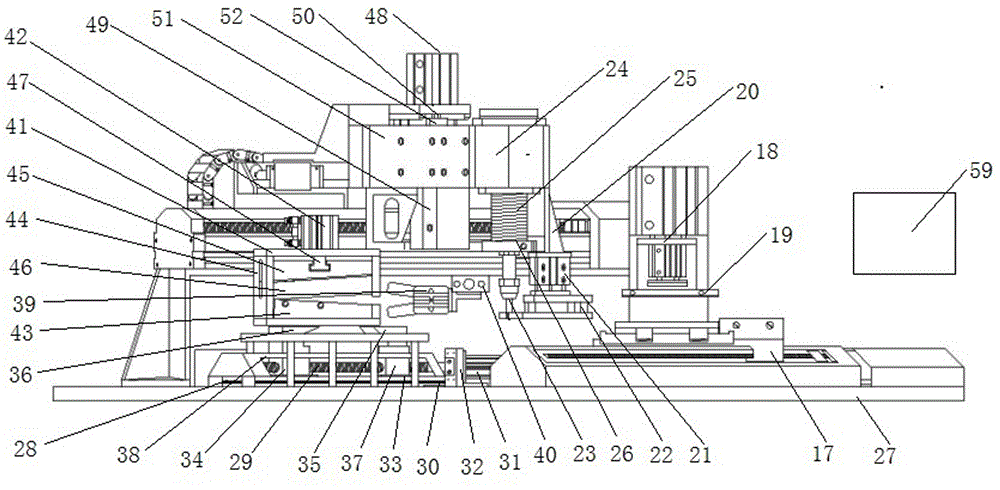

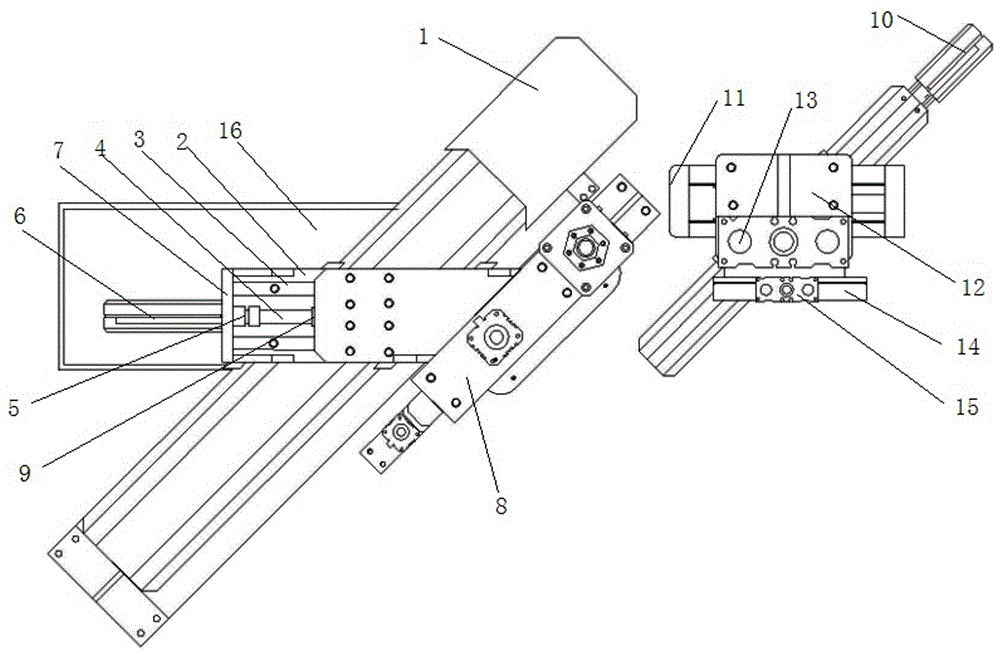

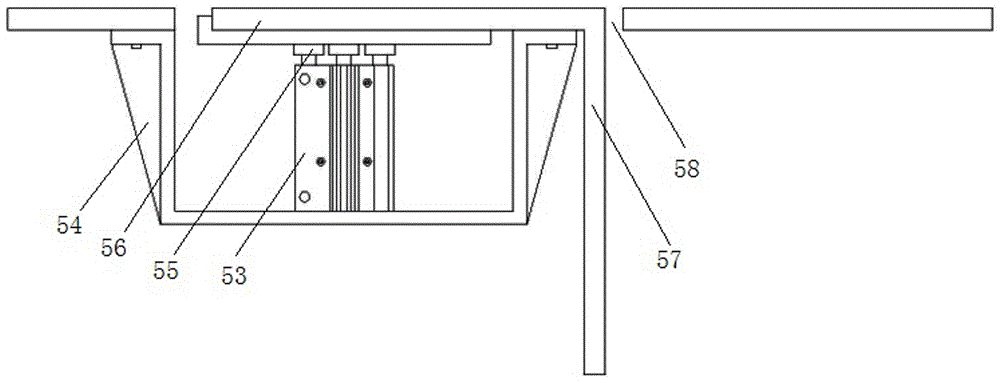

[0019] Such as figure 1 , figure 2 and image 3 As shown, an automatic welding device for the connection of longitudinally wrapped steel strips or aluminum strips of optical cables is composed of a tail positioning device, a head positioning and clamping device, an oblique moving device, a shearing device, a tailing recovery device, a welding device and control system etc.

[0020]Belt tail positioning device: The belt material positioning slide rail 28 is installed on the operation table 27 of the automatic welding device. The positioning servo motor 31 is installed on the console 27 through the fixing seat I 32, and the belt material positioning slide rail 28, the positive and negative screw rod 29 form an angle of 45 degrees with the center line of the production line. Two positioning guide sliders 33,34 are installed on the band material positioning slide rail 28, and oblique opening clamping positioning plate 35,36 is installed respectively on positioning guiding slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com