Numerical control two-face grinding machine for high speed steel circular saw blade

A technology for double-sided grinding machines and circular saw blades, which is applied in the manufacture of tools for grinding machines and sawing machines, and machine tools suitable for grinding workpiece planes, etc. It can solve problems such as high artificial technical requirements, low workpiece processing accuracy, and backward machine tool automation. , to achieve the effect of reducing installation and debugging time, improving workpiece quality, improving physical exertion and technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

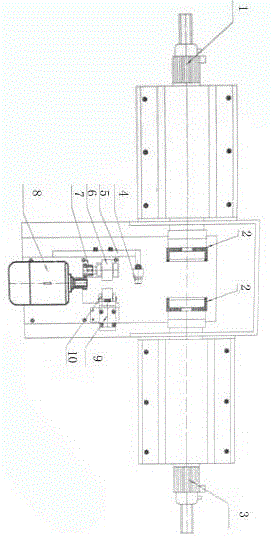

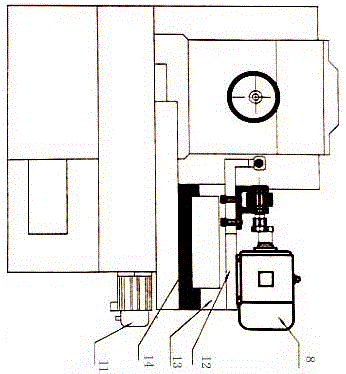

[0015] see figure 1 , figure 2 , the present invention provides a CNC double-sided grinding machine for high-speed steel circular saw blades of thin disc rotary workpieces, which includes a machine base and a PLC digital control system, and is characterized in that: the machine base is a T-shaped structure parallel to the middle of the machine frame There are two sets of grinding wheels, and each set of grinding wheels has a servo motor driving the movement of the grinding wheel, which are respectively X-axis servo motor 1 and Y-axis servo motor 2. The middle part of the machine base is provided with a tooling for clamping workpieces in the vertical direction. The tooling and the control systems of the two sets of grinding wheels are all connected to the PLC digital control system. The tooling includes a supporting part that supports the workpiece and a power part that drives the workpiece to rotate. The supporting part includes a base 12, a feeding Tooling tire 13, base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com