An automatic shot blasting machine for the inner and outer walls of large-diameter steel pipes

A technology of inner and outer walls and shot blasting machines, which is applied in the direction of abrasive jet machine tools, used abrasive processing devices, abrasives, etc., can solve the problems that workers are prone to pneumoconiosis, consume large power, and work for a long time. The effect of increasing the scope of use, high efficiency, and small amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

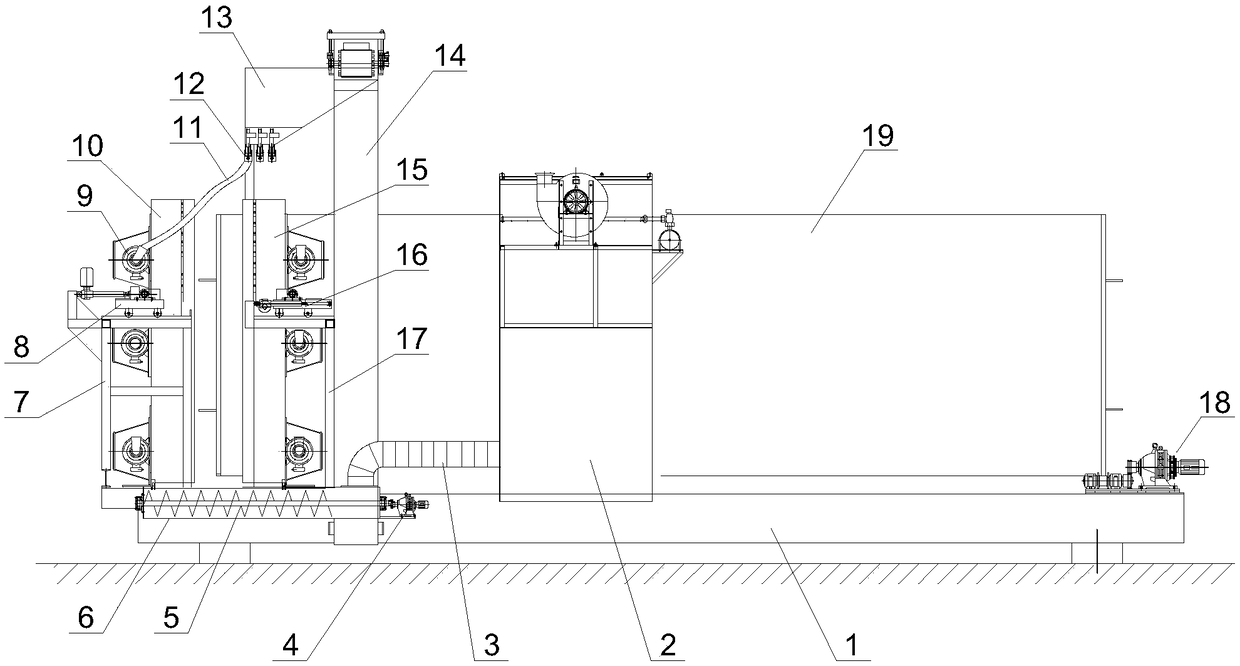

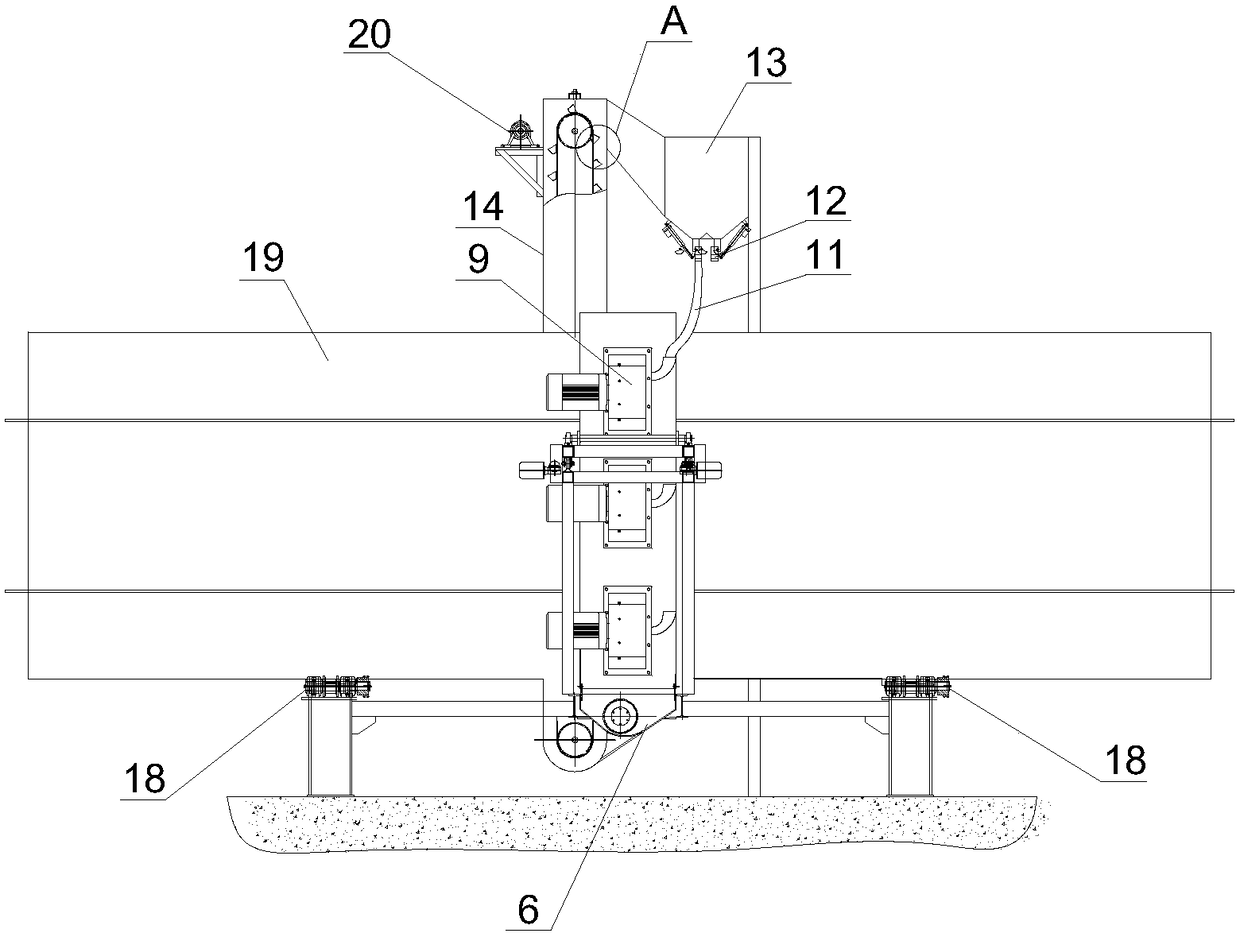

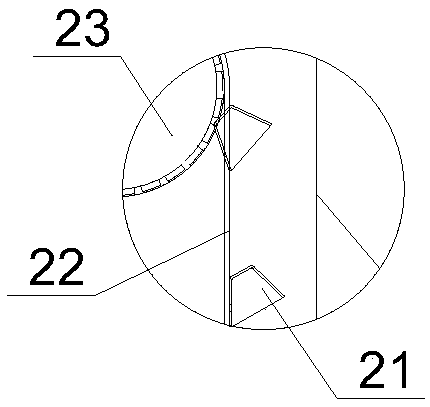

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention includes a frame 1, a steel pipe rotation system, a shot blasting mechanism, a shot material circulation system and a dust removal system, and the frame 1 welded by steel needs to be able to bear a larger steel pipe weight.

[0029] The steel pipe rotation system includes four steel pipe rotation mechanisms 18 installed on the frame 1. The steel pipe rotation mechanism 18 includes a base plate 189, a slideway 181, a drive installation seat plate 188, a rotation drive mechanism 187, a rotating shaft 185 and a steel pipe rotation wheel 184 , the base plate 189 is welded with the frame 1, the slideway 181 is welded on the base plate 189, the drive installation seat plate 188 is installed on the slideway 181 and the installation position can be adjusted, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com