Injection and plasticizing coaxial micro-injection molding machine

A technology of injection molding machine and coaxial line, applied in the field of micro injection molding machine, can solve the problems of complex structure and large volume, and achieve the effect of simple transmission structure, simplified support structure and convenient heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

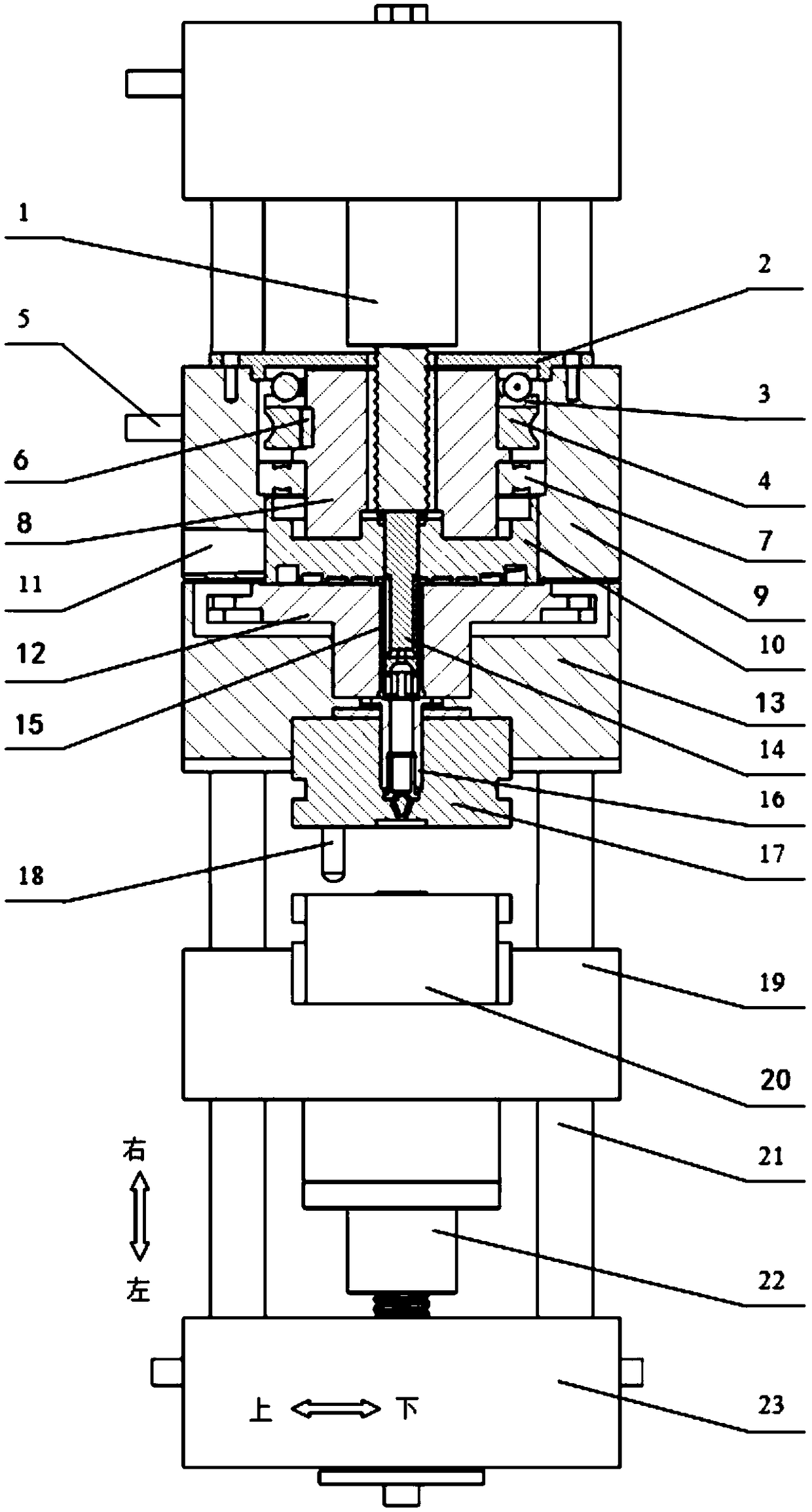

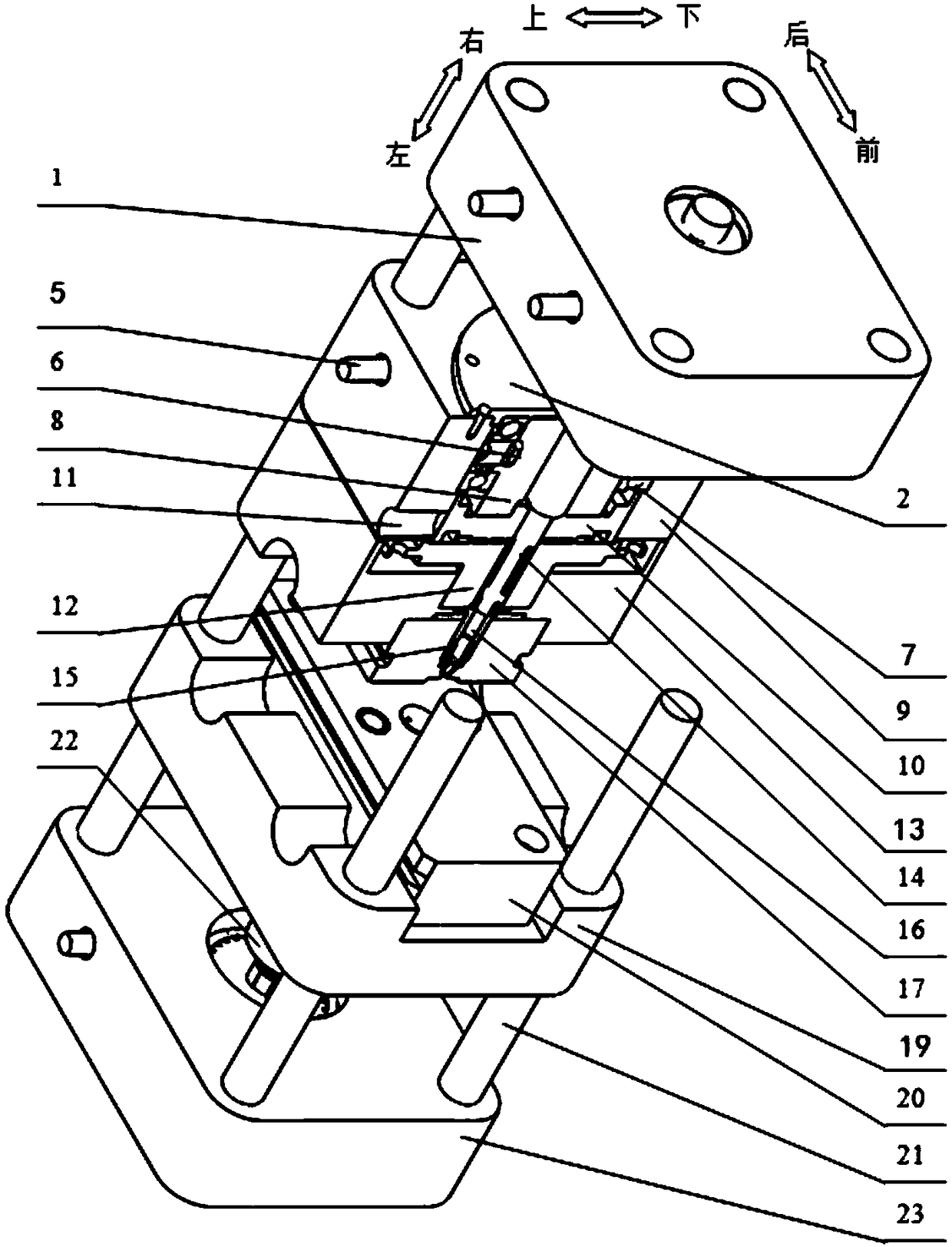

[0029] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the purpose and effect of the present invention will become more obvious.

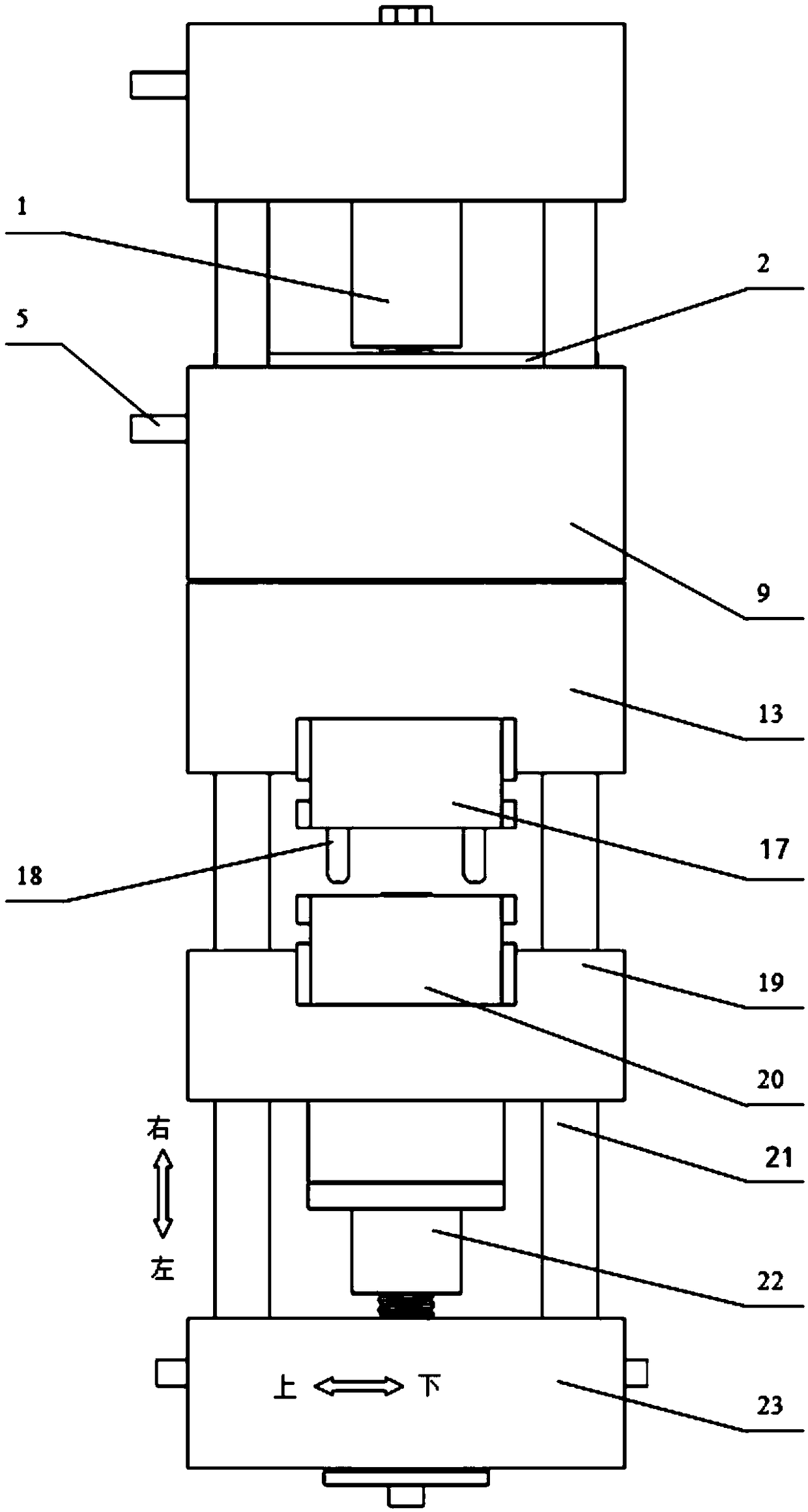

[0030] like figure 1 , figure 2 , image 3 As shown, the present invention provides a micro-injection molding machine coaxial with injection and plasticization, including an injection drive device 1, a grinding disc plasticization device, a mold, a mold clamping drive device 22 and a clamping plate 23 that are sequentially installed on the pull rod ;

[0031] The right end of the injection drive device 1 is a square bottom plate with round holes at the four corners of the bottom plate, and four pull rods 21 pass through the round holes and are fixedly installed.

[0032] like Figure 4 As shown, the injection drive device 1 includes a drive mechanism and a spline ball screw 101, the drive mechanism drives the spline ball screw 101 to realize the reciprocating motion of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com