Profiling polisher for inner wall of annular tread

A grinding machine and annular technology, applied in the field of circular tread inner wall profiling grinding machines, can solve the problems of operator damage, high labor intensity of operators, low production efficiency, etc., achieve uniform grinding surface, and facilitate subsequent processing and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

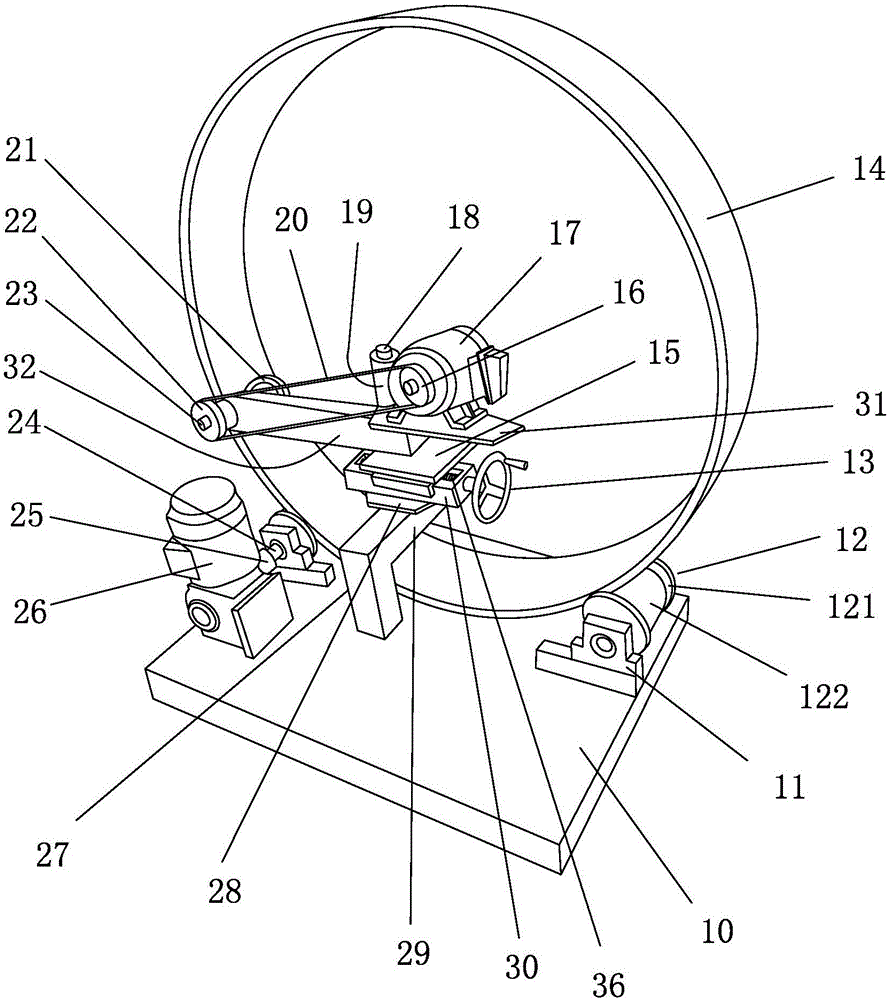

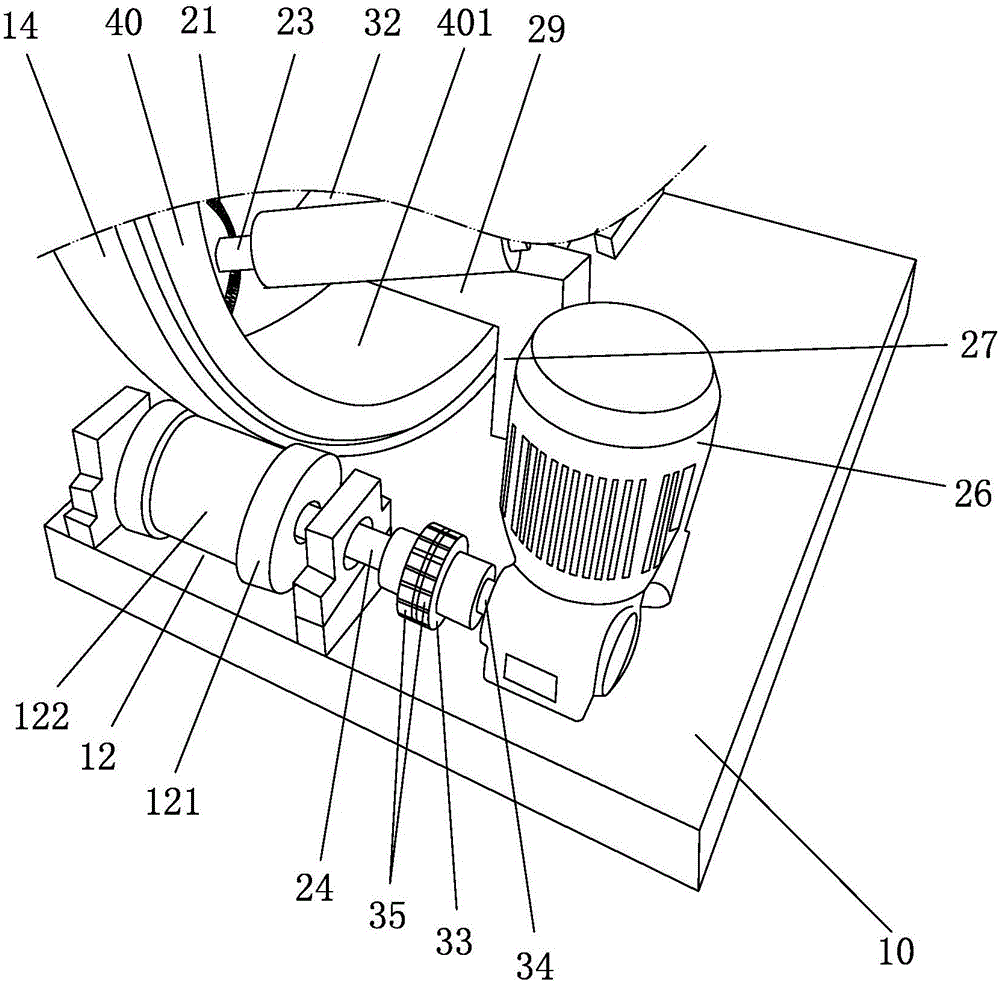

[0023] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — figure 2 :

[0024] The circular tread inner wall profiling grinder includes a base 10, on which two rollers 12 are supported by two supports 11, one of which is fixed on the second roller 12 on the base 10 by one side of the roller 12 A motor 26 or the first air motor drive it to rotate, two rollers 12 are supported with rollers 12 to drive the annular drum 14 that rotates, and the upper arm 29 of the fixed L-shaped support 27 on the base 10 between the two rollers 12 stretches to And be fixed with bracket 28 in the annular drum 14, bracket 28 also can be integrated with upper arm 29 or replace bracket 28 with upper arm 29, slide block 15 is arranged on the horizontal slide rail 30 of bracket 28, slides The fixed vertical shaft 18 on the block 15 is covered with a sleeve 19 that can rotate along the vertical shaft 18. The sleeve 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com