Electric car power cell automatic preheating method

A technology for power batteries and electric vehicles, applied in electric vehicles, secondary batteries, electric traction, etc., can solve the problems of battery capacity attenuation, calculation of warm-up time, and energy recovery rate reduction, so as to improve power performance, safety, and energy efficiency. Reduce vehicle power consumption and increase the effect of energy recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

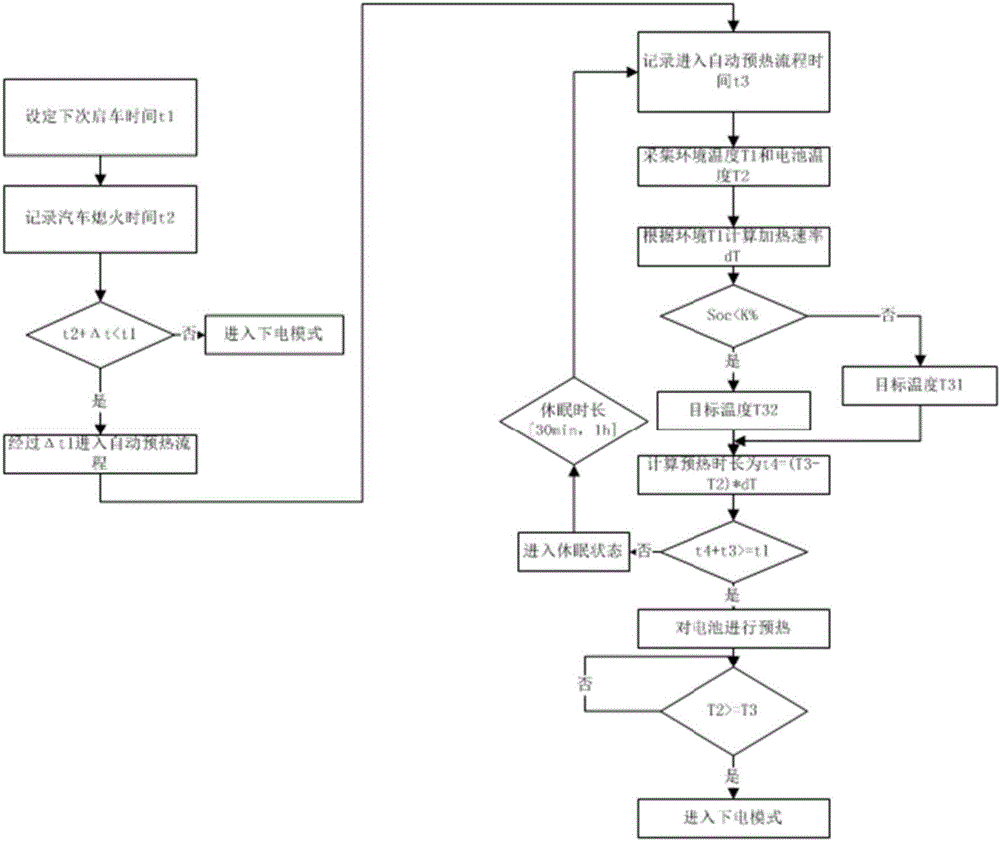

Method used

Image

Examples

Embodiment 1

[0067] The driver stopped at 18:00 on September 14, 2016 and artificially set the next start-up time as t1 = 6:00 on September 15, 2016. After the driver closed the vehicle, he recorded the car's flameout time t2 = September 14, 2016 18:05.

[0068] It should be noted that in Embodiment 1, the preset duration Δt1 is 2 hours, which is the best value obtained from experimental data according to the heat preservation and heat dissipation state of the power supply, and can of course be determined according to the actual vehicle condition Adjust accordingly.

[0069] According to the judgment condition, whether the interval between the next start-up time t1 and the car flameout time is greater than the preset time length Δt, if so, the vehicle enters the automatic preheating process for the first time after the preset time length Δt1, and records the time t3 when entering the automatic preheating process. Specifically, when making judgments and comparisons, the time format is year...

Embodiment 2

[0079] The driver stopped at 18:00 on September 14, 2016 and artificially set the next start-up time as t1 = 19:00 on September 14, 2016. After the driver closed the vehicle, he recorded the car's flameout time t2 = September 14, 2016 18:05.

[0080] According to the judgment condition, whether the time interval between the next start-up time t1 and the engine-off time of the car is greater than the preset duration Δt, in this embodiment, the preset duration Δt1 is 3 hours, if so, enters the automatic preheating process, after preheating After setting the time length Δt1, it enters the automatic preheating process time t3. Specifically, when making judgments and comparisons, the format of the time is year, month, day, hour, minute, and second. In this example, the complete format of the next start-up time t1 is 19:00 on September 14, 2016, and the complete format of the car’s flameout time t2 The format is 18:05 on September 14, 2016. In the program, first determine whether t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com