Solid-liquid phase transition brine concentration method

A solid-liquid phase, brine technology, applied in the direction of chilled water/sewage treatment, etc., can solve the problems of high one-time investment and operating costs, low investment and operating costs, etc., and achieve outstanding energy-saving effect, low cost and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

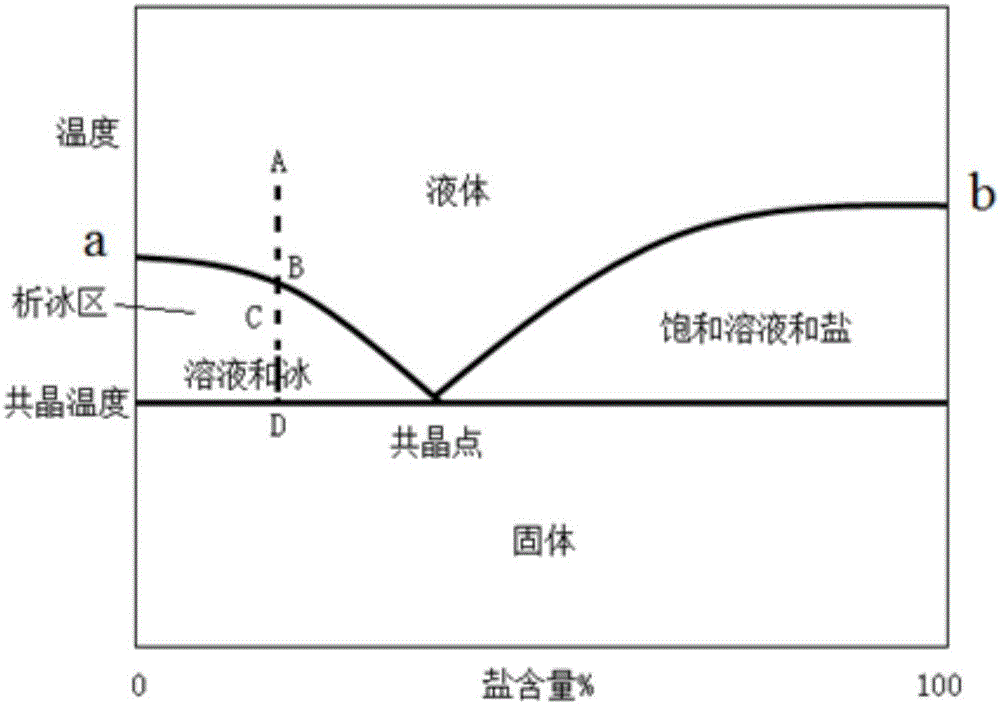

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The solid-liquid phase conversion brine concentration method of the present invention comprises the steps of:

[0025] A. Prepare a plurality of cold storage containers, and store a cold storage agent with a freezing point below 0°C in the cold storage containers;

[0026] B. Place a plurality of cold storage containers in the cold storage pool, the cold storage pool lowers the temperature inside the cold storage pool through the refrigeration system, and the temperature of the cold storage agent in the cold storage container from the frozen cold storage container is lower than 0 °C;

[0027] C, placing a plurality of cold storage containers obtained by step B in the freezing pool, introducing the brine that needs to be concentrated into the freezing pool, and allowing the cold storage containers to be immersed in the brine that needs to be concentrated;

[0028] D. When the surface of the cold storage container in the freezing pool is frozen, take out the cold storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com