A kind of foaming agent for coalbed methane reservoir drilling and its preparation method and application

A technology of coalbed methane and foaming agent, which is applied in the field of coalbed methane reservoir drilling, can solve the problems of lack of foaming agent, etc., and achieve the effects of keeping the wellbore clean, good upper formation leakage prevention and plugging, and good foam performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

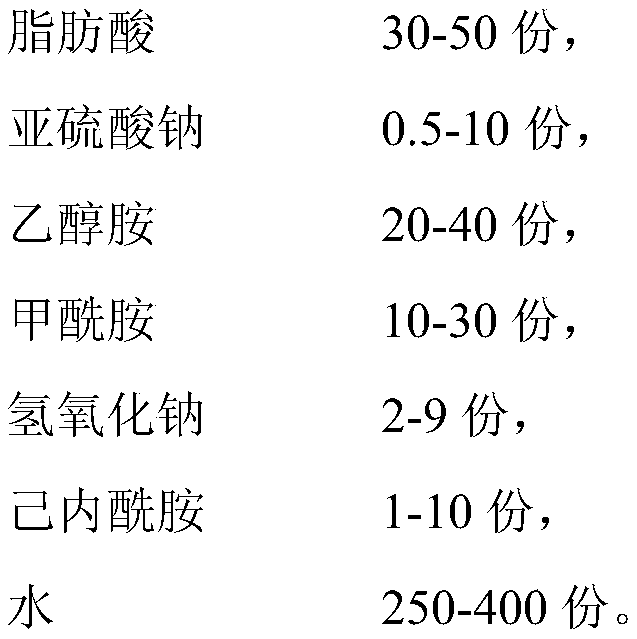

[0026] This embodiment provides a foaming agent for coalbed methane reservoir drilling, in parts by weight, the raw material components of the foaming agent for coalbed methane reservoir drilling include:

[0027]

[0028] The present embodiment also provides a preparation method of the above-mentioned foaming agent for coalbed methane reservoir drilling, which includes the following steps:

[0029] Step 1: Add lauric acid, sodium sulfite, ethanolamine, sodium hydroxide and water into the reaction kettle with enamel substrate according to the amount of raw materials added above, and heat up to 130°C under constant stirring;

[0030] Step 2, then add formamide and caprolactam according to the above raw materials, continue heating and stirring at 130°C for 6 hours, stop stirring when cooling to 90°C, and naturally cool to room temperature to obtain a yellow or light yellow liquid, which is coalbed methane drilling Use foaming agent.

[0031] This embodiment also provides the...

Embodiment 2

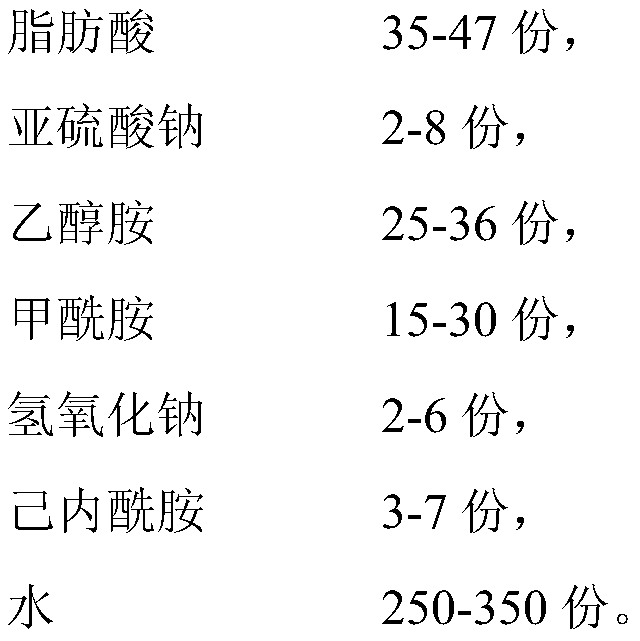

[0034] This embodiment provides a foaming agent for coalbed methane reservoir drilling, in parts by weight, the raw material components of the foaming agent for coalbed methane reservoir drilling include:

[0035]

[0036] The present embodiment also provides a preparation method of the above-mentioned foaming agent for coalbed methane reservoir drilling, which includes the following steps:

[0037] Step 1: Add lauric acid, sodium sulfite, ethanolamine, sodium hydroxide and water into the reaction kettle with enamel substrate according to the amount of raw materials added above, and heat up to 130°C under constant stirring;

[0038] Step 2, then add formamide and caprolactam according to the above raw materials, continue heating and stirring at 130°C for 6 hours, stop stirring when cooling to 90°C, and naturally cool to room temperature to obtain a yellow or light yellow liquid, which is coalbed methane drilling Use foaming agent.

Embodiment 3

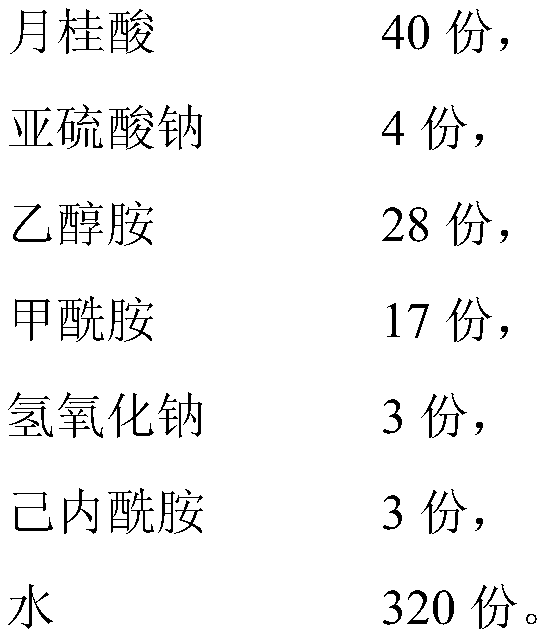

[0040] This embodiment provides a foaming agent for coalbed methane reservoir drilling, in parts by weight, the raw material components of the foaming agent for coalbed methane reservoir drilling include:

[0041]

[0042] The present embodiment also provides a preparation method of the above-mentioned foaming agent for coalbed methane reservoir drilling, which includes the following steps:

[0043] Step 1: Add palmitic acid, sodium sulfite, ethanolamine, sodium hydroxide and water into a reaction kettle with an enamel substrate according to the amount of raw materials added above, and heat up to 130°C under constant stirring;

[0044] Step 2, then add formamide and caprolactam according to the above raw materials, continue heating and stirring at 130°C for 6 hours, stop stirring when cooling to 90°C, and naturally cool to room temperature to obtain a yellow or light yellow liquid, which is coalbed methane reservoir drilling Use foaming agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com