Special hanger for surface anodizing

A technology of anodic oxidation and hanger, which is applied in the direction of anodic oxidation, surface reaction electrolytic coating, coating, etc., can solve the problems that the oxidation quality of the product cannot be guaranteed, there is no special use of reliable hangers, and the efficiency of hanging and picking workpieces is affected. The installation is convenient and fast, the effect of improving the oxidation effect and meeting the needs of humanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

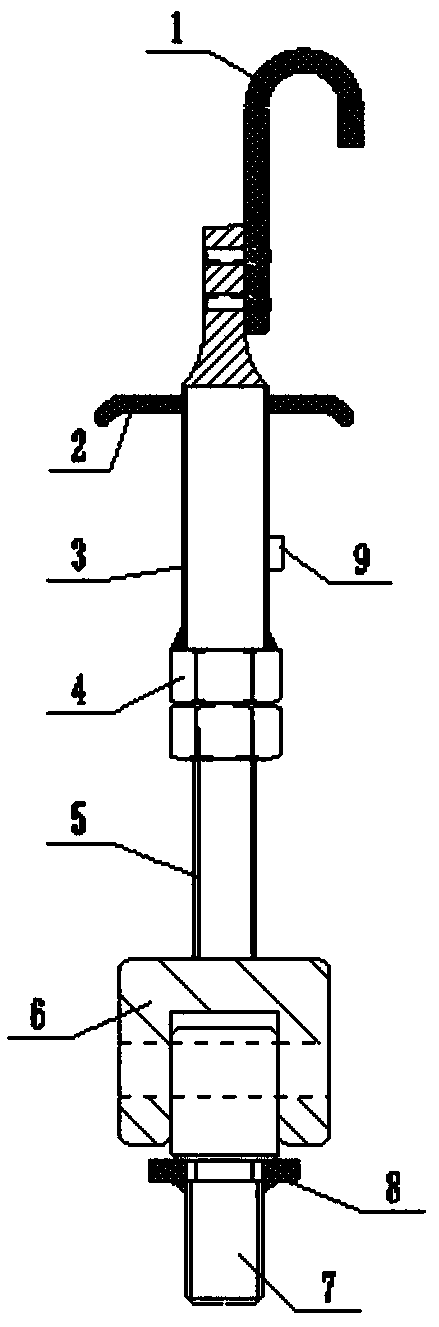

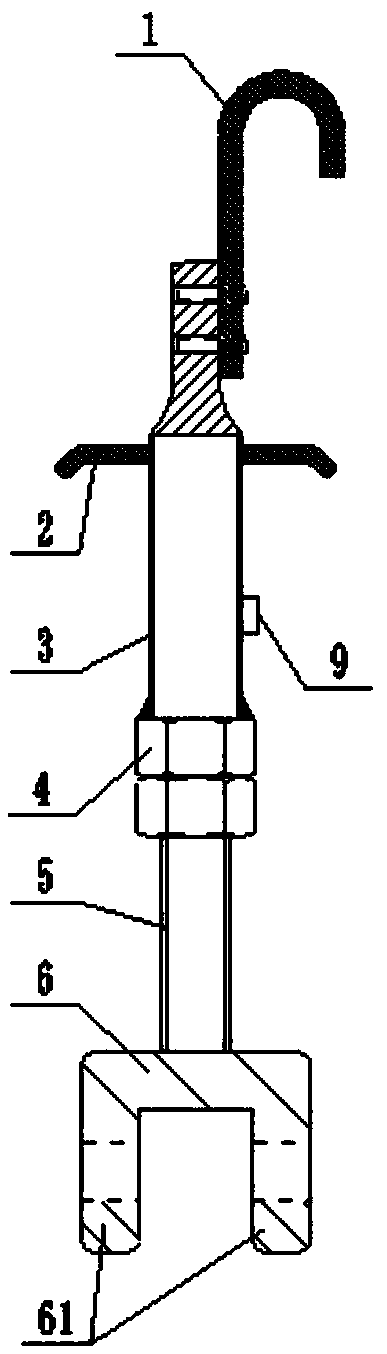

[0040] In order to improve the strength and operability of the hanger of the present invention, the structure and connection of the fixed hook 6 and the threaded post 7 are optimized, as image 3 , Figure 5 As shown, the fixed hook 6 is provided with two hinged ears 61, the stud head 71 is hinged between the two hinged ears 61, and the cross section of the stud head 71 is set as an oblate or square structure;

Embodiment 2

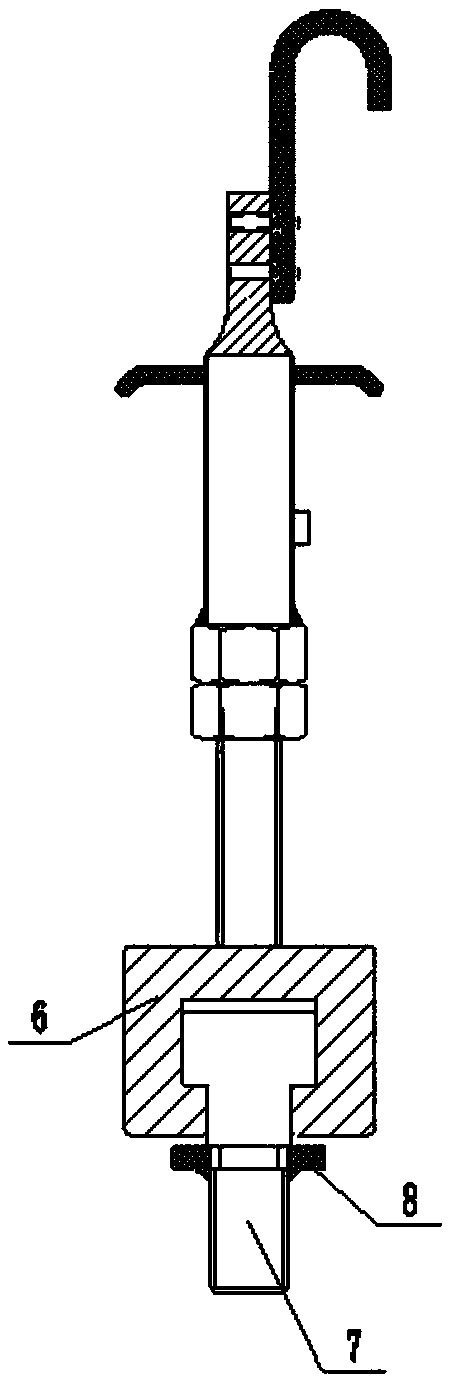

[0042] Such as Figure 4 , Image 6 As shown, the fixed hook 6 is provided with a T-shaped groove 62, and the stud head 71 is set as a T-shaped structure to cooperate with the T-shaped groove 62 of the fixed hook 6. This structure can avoid the process of inserting the hinge shaft, and the operation is simpler , in order to ensure the stability when the threaded post 7 is connected with the fixed hook 6, such as Figure 7 As shown, the T-shaped slot 62 is provided with a positioning slot 63 for positioning the stud head 71 . Of course, the connection relationship between the fixed hook 6 and the threaded column 7 can also be set as threaded connection, hook connection, etc., which will not be repeated here, and all these equivalent forms also fall within the scope of protection defined by the present application.

[0043] In order to facilitate the loading and unloading of the hanger and meet the needs of humanization, the present invention has a handle 2 on the main rod, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com