A ballastless track embankment structure in salt-rich soft saline soil area

A ballastless track and saline soil technology, used in roads, tracks, infrastructure projects, etc., can solve problems such as damage to buildings and economic losses, prevent secondary salinization of embankments, ensure stability, and meet settlement requirements. desired effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments in conjunction with the drawings.

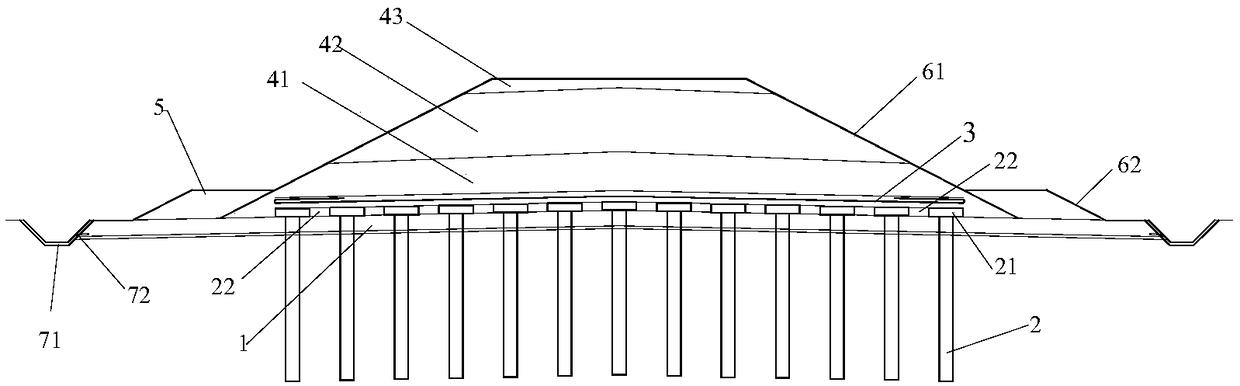

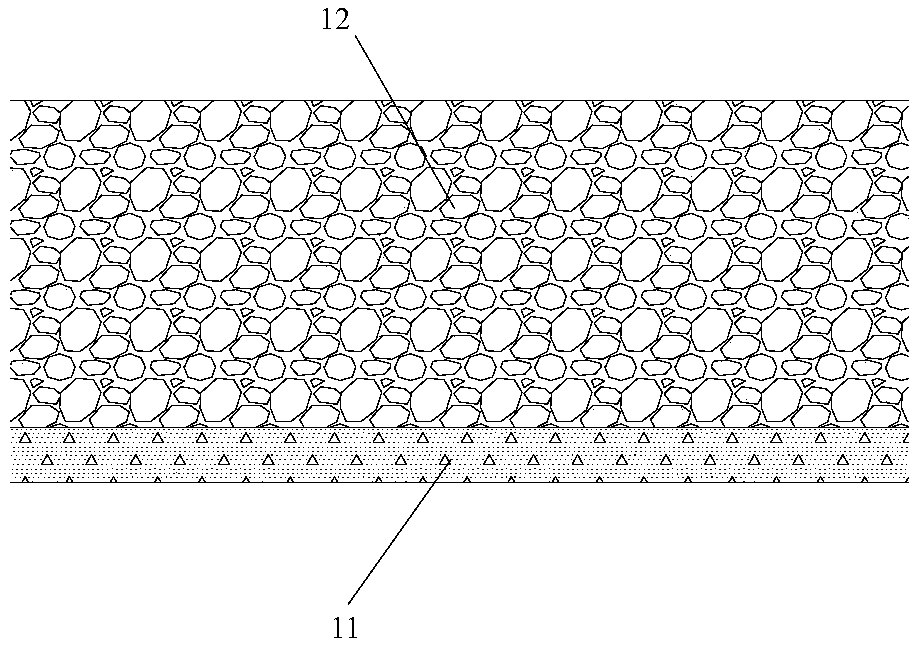

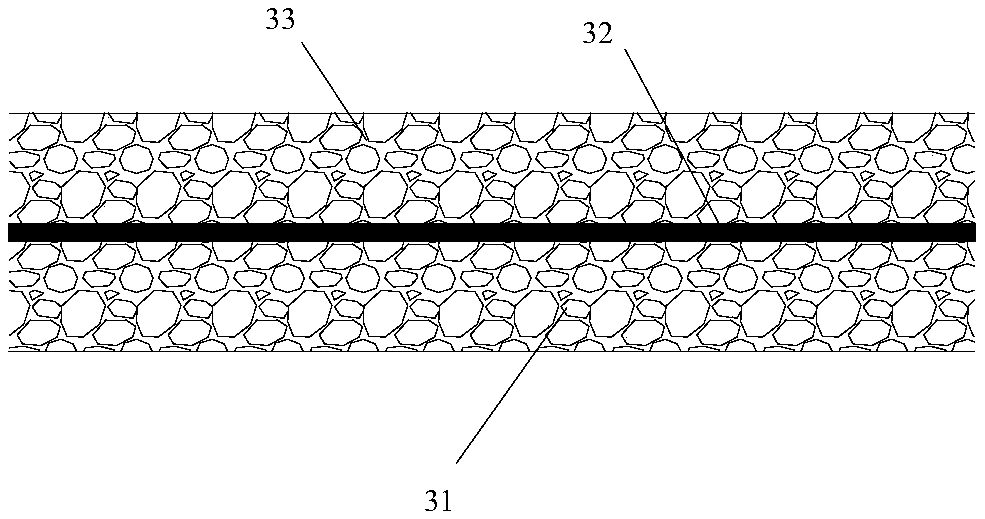

[0016] Reference figure 1 A ballastless track embankment structure in the salt-rich weak saline soil area of the present invention includes: a drainage salt layer 1 arranged on the surface layer of the salt-rich weak saline soil foundation; anti-corrosion reinforcement piles 2, longitudinally and horizontally spaced apart In the weak saline soil foundation; the anti-sagging reinforced cushion 3, laid on the anti-corrosion reinforced pile 1; embankment 4, filled on the anti-sagging reinforced cushion 3; back pressure protection road 5, filling Outside the slope toe on both sides of the embankment 4; drainage system 7, including drainage ditch 71 and inclined drainage salt drainage hole 72, drainage ditch 71 is set outside the drainage salt drainage layer 1, the inclined drainage salt drainage hole 72 is along the longitudinal direction of the line The int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com