Plaza drainage brick based on honeycomb structure

A technology of honeycomb structure and square is applied in the field of square bricks to achieve the effect of saving the cost of purchasing bricks, increasing the daily output and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

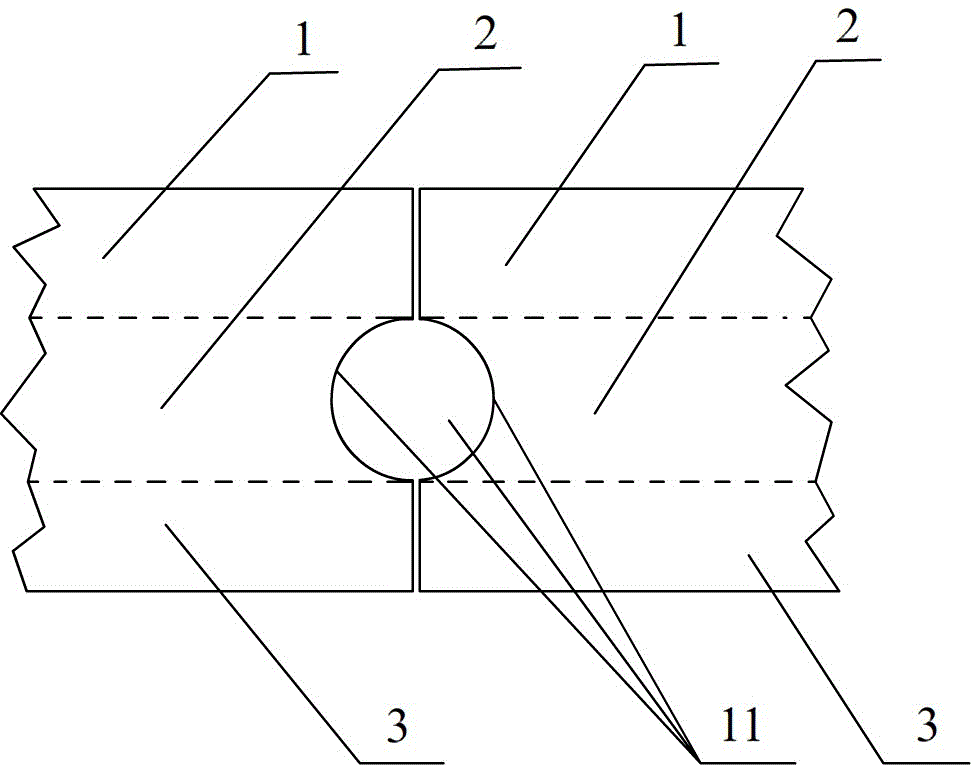

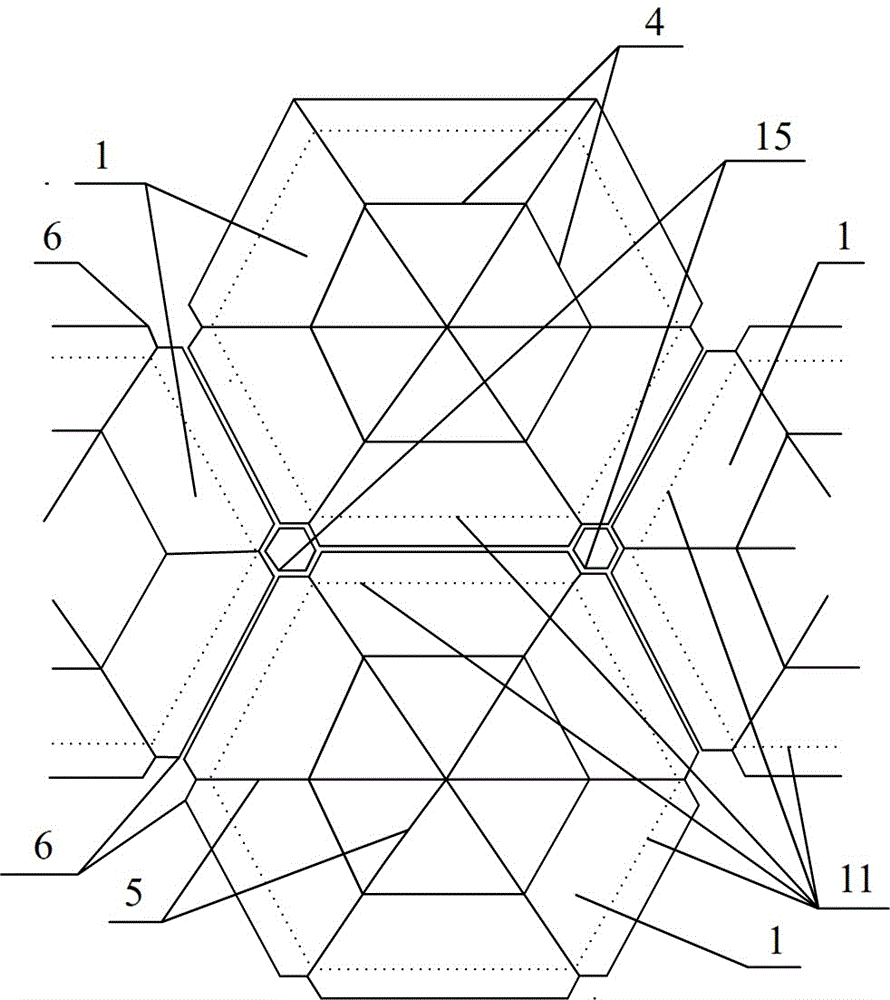

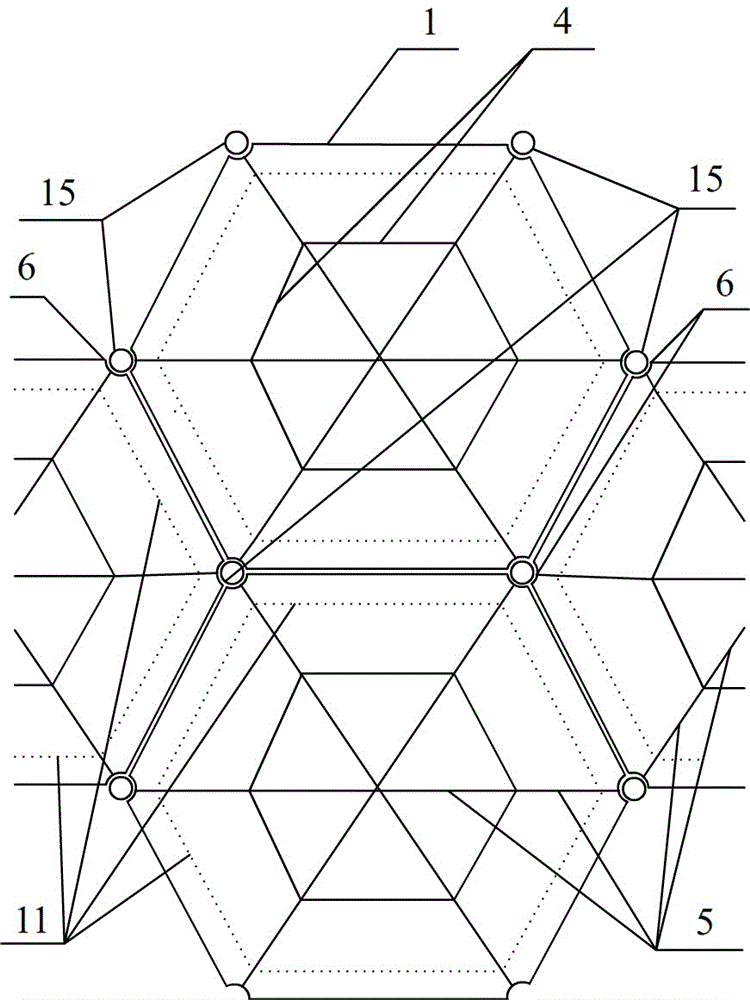

[0022] Such as figure 1 As shown, a square drainage brick based on a honeycomb structure is composed of a brick body, a vertical drainage hole, a sedimentation tank, and a horizontal semicircular drainage hole. It is characterized in that it includes a brick body A1, a brick body B2, and a brick body C3. Polygonal shallow water tank 4, diagonal shallow water tank 5, inlet and outlet holes 6, longitudinal section A7, longitudinal section B8, longitudinal section C9, longitudinal section D10, semicircular drainage hole 11, curved surface pool 12, sedimentation tank 13, pool Bottom surface 14, sand collecting bucket 15; described brick body is hexagonal, is formed by die-casting superimposed up and down of brick body A1, brick body B2, brick body C3, and the upper surface of described brick body A1 design polygonal shallow water tank 4, pair Diagonal line shallow water tank 5, inlet and outlet openings 6; the polygonal shallow water tank 4 is located in the middle of the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com