A device and method for improving pile bearing capacity and stability

A technology of bearing capacity and stability, applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of poor stability, difficulty, design and construction difficulties, etc., to reduce the size and embedding depth, and improve the bearing capacity Strength and stability, the effect of convenient construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

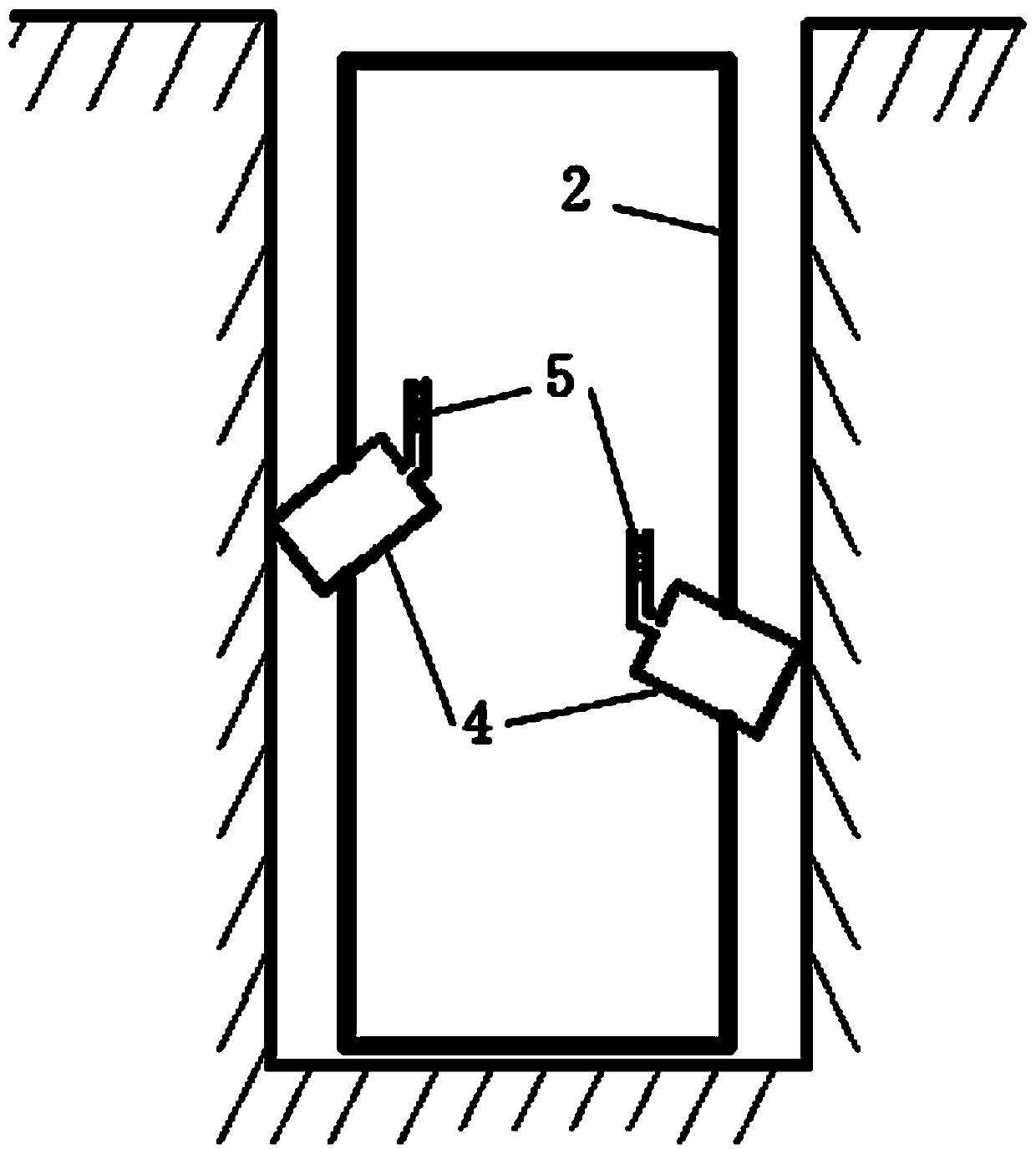

[0025] Such as figure 1 As shown, a device for improving pile bearing capacity and stability includes a plurality of extendable branch piles 4 arranged on the wall of the main pile 2, and the main pile 2 is connected with each extendable branch pile 4 to form a overall;

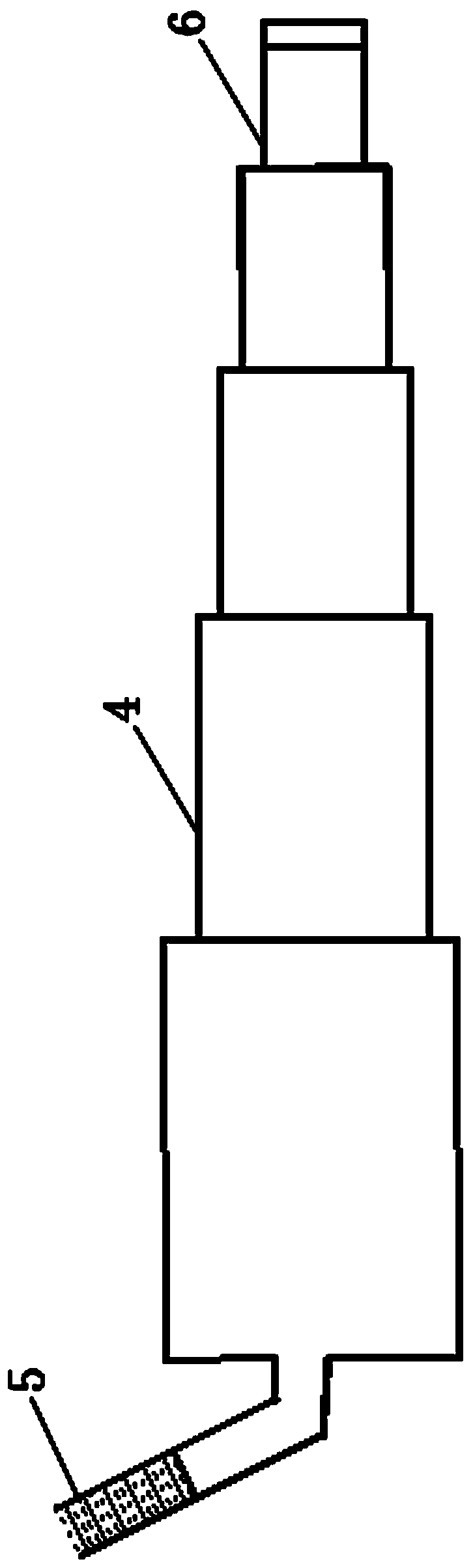

[0026] In the extendable branch pile 4, the main body of the branch pile is connected with an air inlet 5, and the telescopic joint is connected with the main body of the branch pile. The telescopic joint is composed of N connected telescopic joints, N≥1;

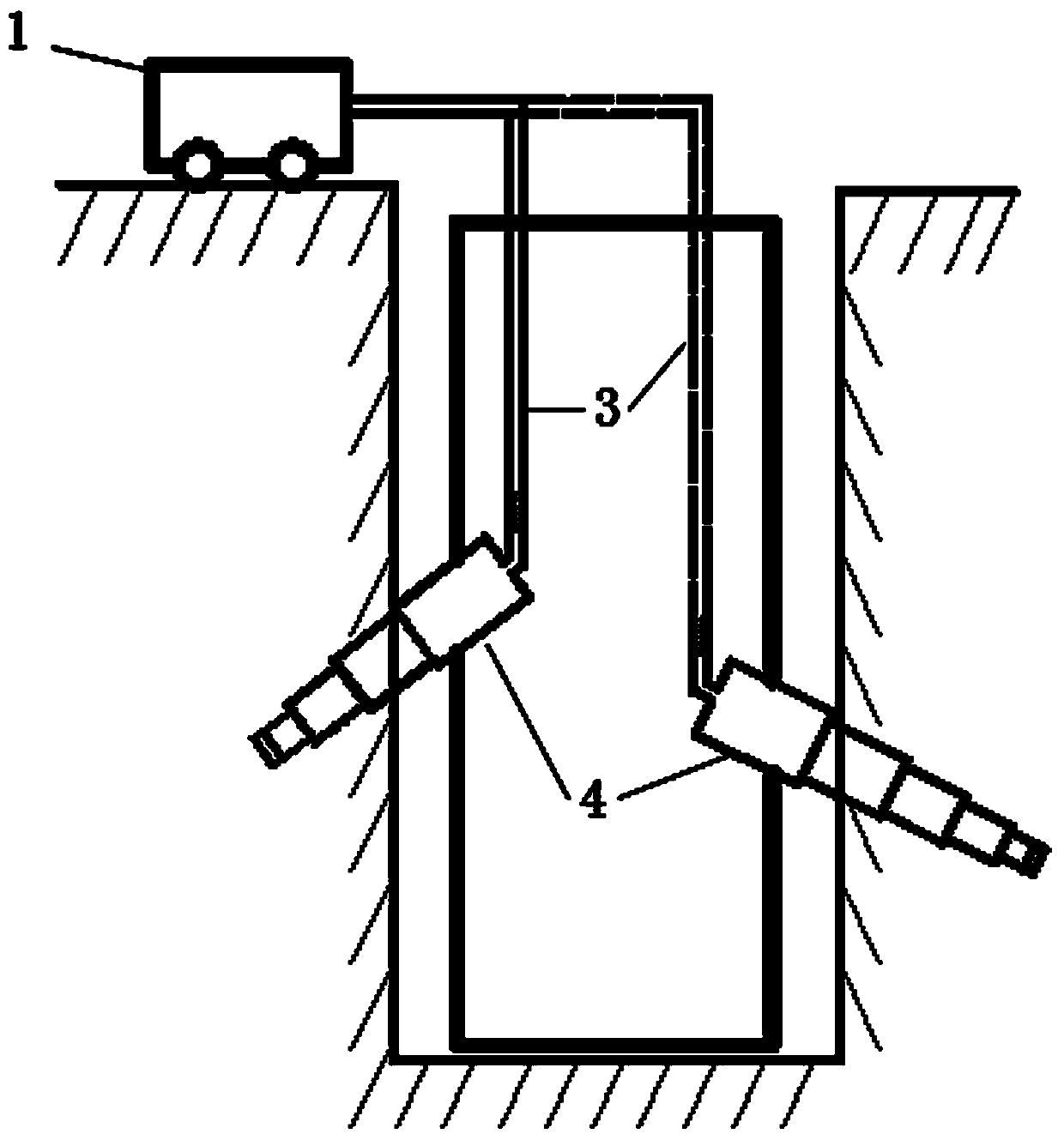

[0027] The air delivery device is matched with the air inlet of each expandable branch pile 4.

[0028] A plurality of expandable branch piles 4 are arranged at the designed position on the main pile 2 . The position of each extendable branch pile 4 and the joint angle with the main pile 2 can be set. The number and length of each extendable branch pile 4 can be customized. The extendable branch pile 4 is initially in a contracted state. Air pipe 3 to t...

Embodiment 2

[0030] The cross-sectional shape of the extensible branch pile 4 can be determined according to the actual engineering, image 3 It is a square extendable branch pile 4, Figure 4 It is a triangular extensible branch pile 4. In order to make it easier to insert the extensible branch pile into the soil, the innermost section 6 of the extensible branch pile 4 is designed as a flat pointed shape.

Embodiment 3

[0032] The main pile 2 is a rigid pile, and each extendable branch pile 4 is fixedly installed on the main pile 2 according to the designed angle position so that the main pile 2 and each extendable branch pile 4 are connected by welding or threaded connection to form a overall.

[0033] In the gas transmission device, each expandable branch pile 4 recycles a pressure-resistant gas pipeline 3, and the pressure-resistant gas pipeline 3 is screwed and sealed with the air inlet 5 of the expandable branch pile 4 through the threaded end 7, as Figure 5 shown.

[0034] Another way of the gas transmission device is that each extendable branch pile 4 is equipped with a pressure-resistant gas transmission pipe 3 respectively, and the pressure-resistant gas transmission pipe 3 is attached to the main pile 2 through the support body 9, and is connected to the main pile 2 through the seamless welding end 8. Connect with the air inlet 5 of the extendable branch pile 4, such as Figure 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com