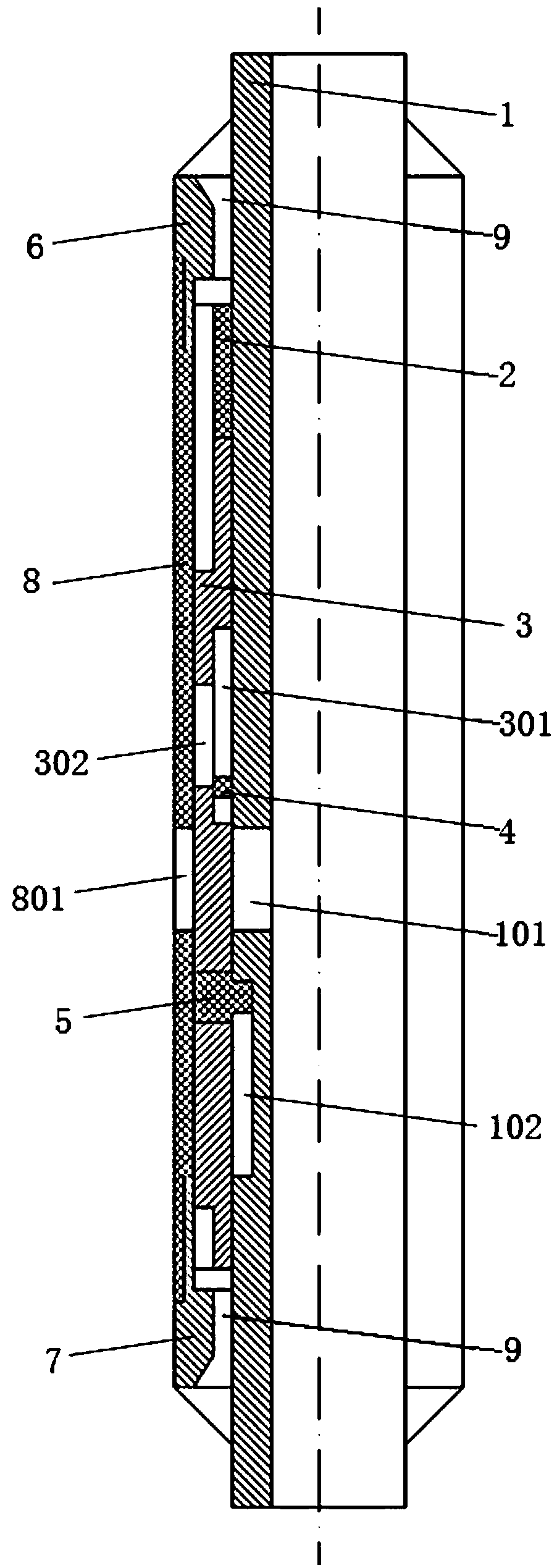

A hydraulic control valve

A technology of hydraulic control valve and sliding sleeve, which is applied in the direction of wellbore/well valve device, wellbore/well parts, sealing/packing, etc., which can solve the problem of affecting reliability and service life, and the durability of the electromechanical integrated module of hydraulic control valve. Problems such as safety and stability, to protect the guide pins, improve reliability, and prolong the life of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

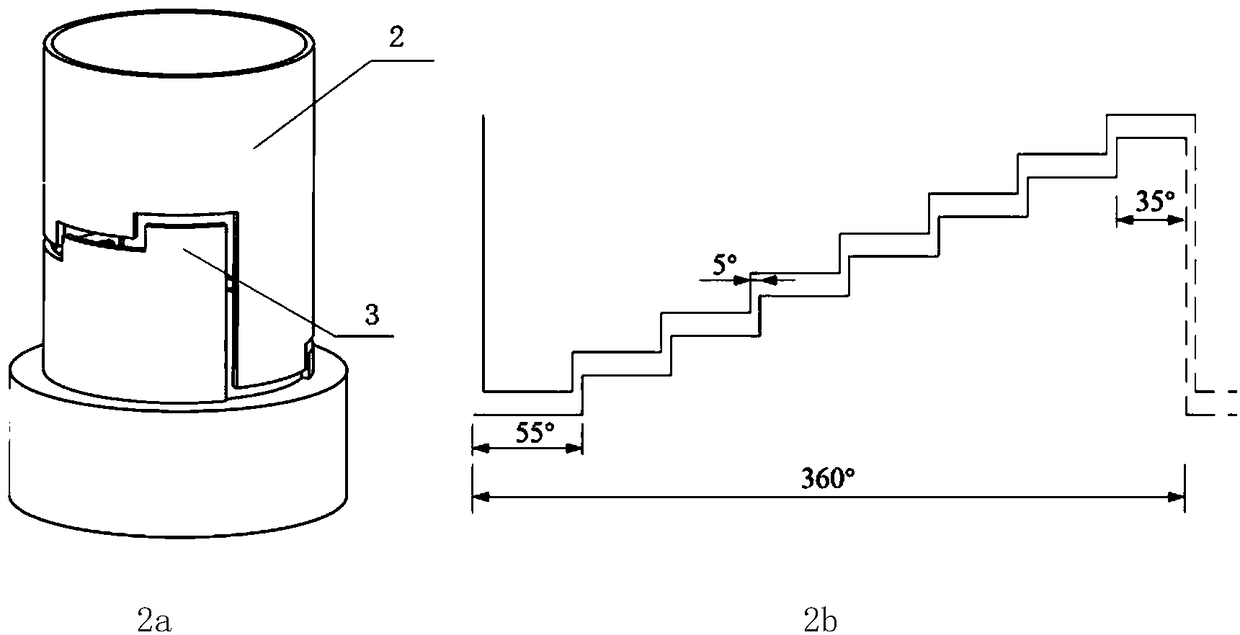

[0030] figure 2 It is an embodiment of the structure corresponding to the upper end of the upper limit structure 2 and the sliding sleeve 3, wherein, the lower end surface of the upper end surface of the upper limit structure 2 and the upper end surface of the helical structure of the sliding sleeve 3 are both set in a stepped shape, and a stepped fit is adopted . figure 2b for figure 2 a The three-dimensional structure is developed along the circumference of the phase coordination diagram, the control valve has eight gears, and the shifting action of the sliding sleeve 3 is roughly divided into the following three steps:

[0031] (1) Inject liquid into the interior through the hydraulic pipeline 9, drive the sliding sleeve 3 to move downward, and the upper helical structure of the sliding sleeve 3 is completely disengaged from the upper limit structure 2 (that is, the stepped helical structure at the upper end of the sliding sleeve 3 rotates around the axis During the mo...

Embodiment 2

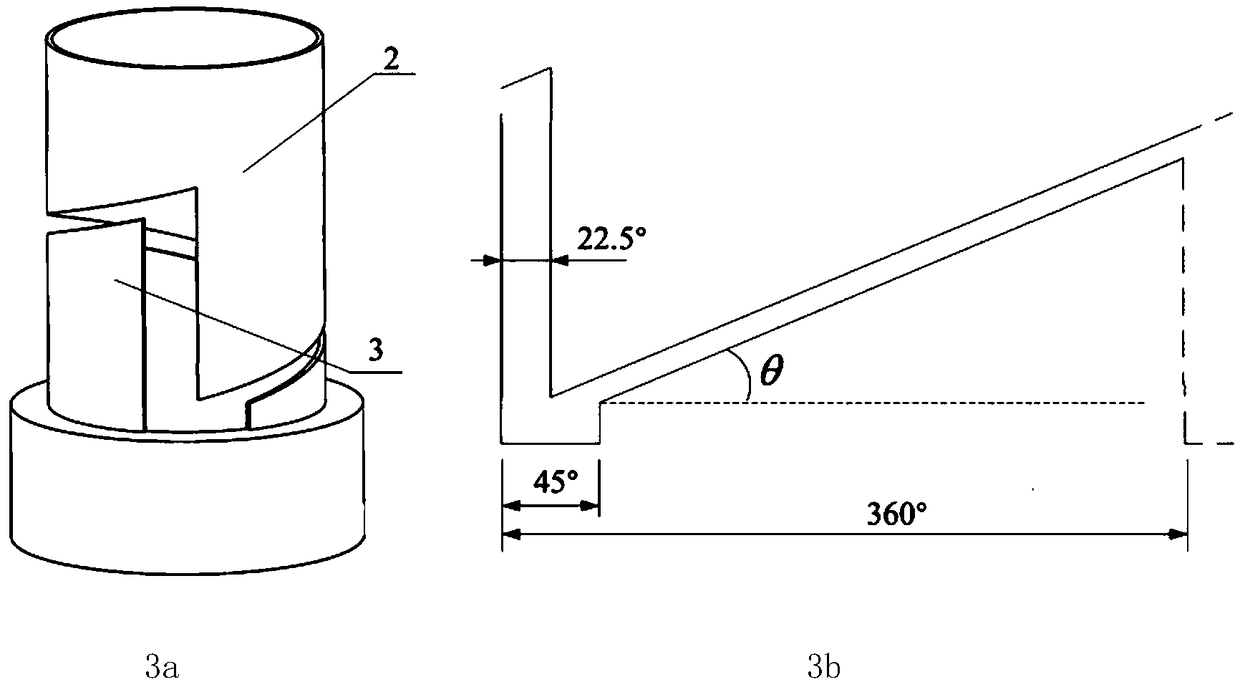

[0036] image 3 It is another embodiment of the structure corresponding to the upper end of the upper limit structure 2 and the sliding sleeve 3, wherein, the lower end surface of the upper limit structure 2 helical structure and the upper end surface of the sliding sleeve 3 helical structure are set as planar, and the spiral plane type is adopted. cooperation. image 3 b for image 3 a The phase coordination diagram of the three-dimensional structure developed along the circumference, and the control valve has eight gears.

[0037] In order to avoid jamming during the shifting action and affect the reliability of the system, the helical planar fit is also set with a 45° "non-contact phase". Compared with the stepped fit, the continuously changing spiral planar fit is easier to process and fine-tune the system, but because the limit structure needs to resist the rotational movement of the sliding sleeve 3 relative to the central tube 1 while bearing the axial force, so When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com