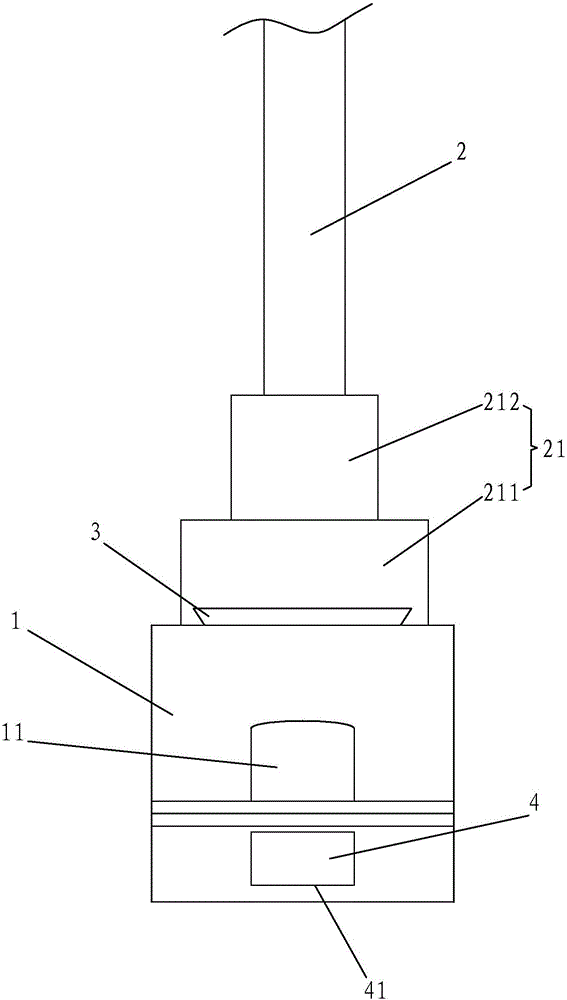

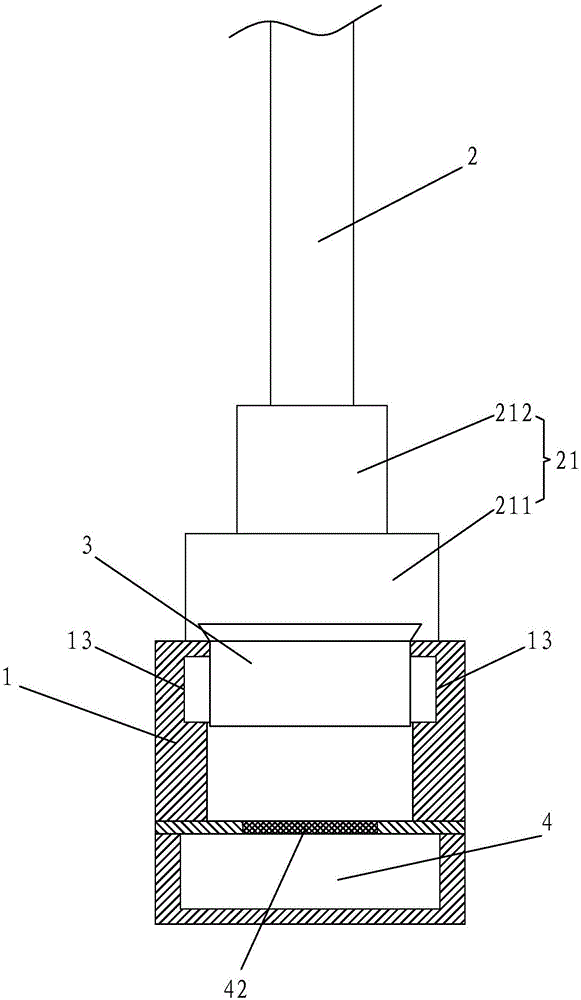

Energy-saving plant fuel cooking stove

A fuel-based, energy-saving technology, applied in the field of daily life, can solve the problems of stoves that cannot efficiently use fuel heat, long cooking time, and enhanced practicability, and achieve significant environmental protection and safety features, shorten cooking time, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

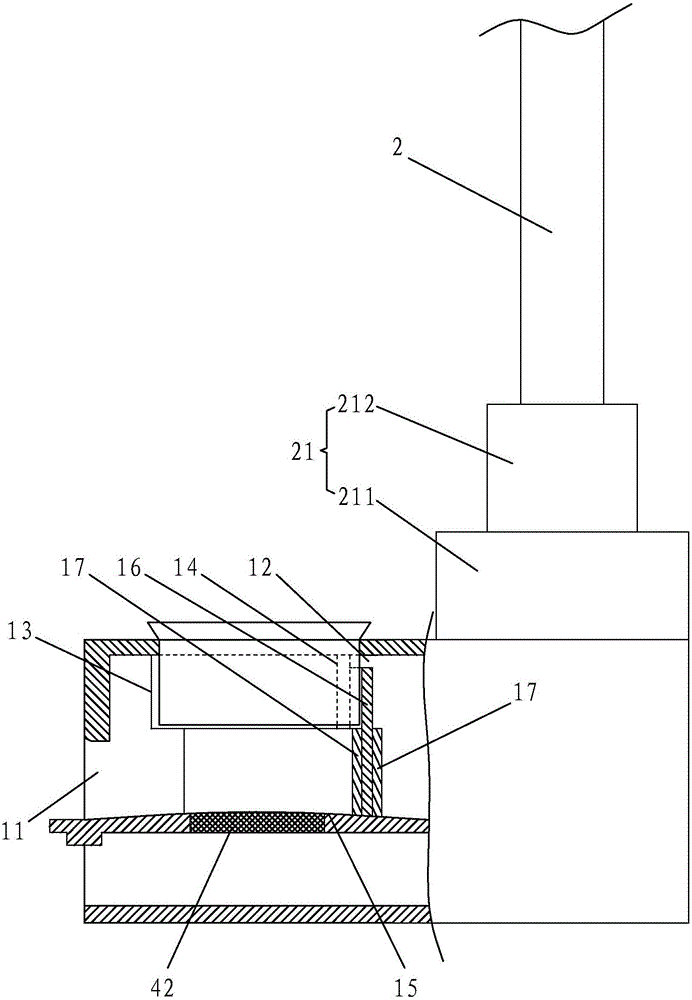

[0087] In order to further enhance the smoke storage capacity of the tempering tank 13 and the entire cooking chamber, another implementation is adopted according to the flow characteristics and heat dissipation characteristics of the flame, smoke and hot air. Preferably, the lower edge of the tempering tank 13 is lower than The bottom of the pot 3 is below the edge of the bottom of the pot, and the distance between the lower edge of the tempering tank 13 and the bottom of the pot 3 is 0.5-2cm. Tempering groove 13 constitutes tempering passage like this, can make flame, smoke and hot air etc. enter tempering groove 13 by the gap between the lower edge of tempering groove 13 and the sidewall of pot 3 and form in tempering groove 13 The flame is circulated to heat the pot 3 evenly and fully. The specific size of the distance between the lower edge of the tempering tank 13 and the side wall of the pot 3 can be adjusted and designed according to actual requirements.

[0088] Pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com