Automatic leakage detector of container vessel

An automatic detection and utensil technology, which is applied in the direction of detecting the appearance of fluid at the leak point and using liquid/vacuum degree for liquid tightness measurement. It can solve the problems of large detection error and slow detection speed, and achieve simple operation and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

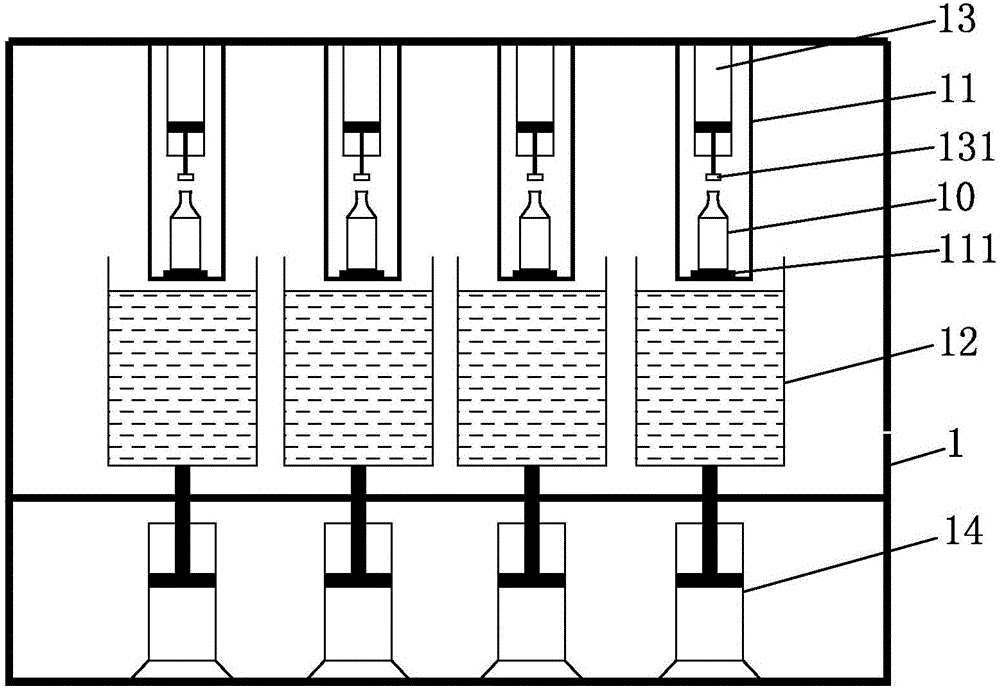

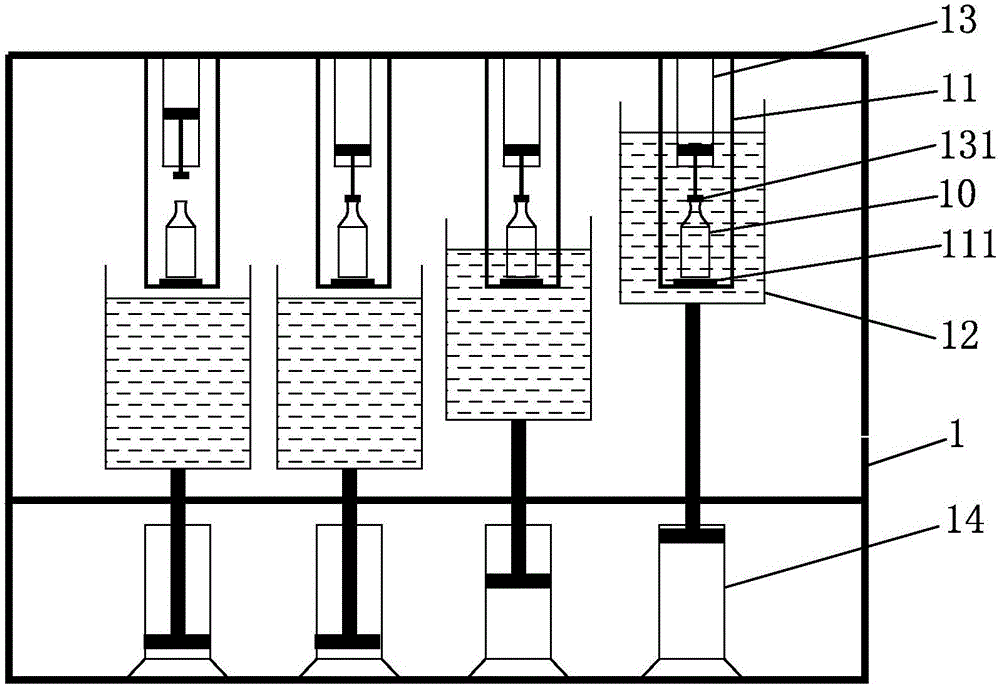

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] see Figure 1-Figure 2 , the automatic leak detection machine for containers and utensils, including a frame 1, the frame 1 is provided with a workpiece seat 11 for placing the workpiece 10 to be tested, and the frame 1 and / or the workpiece seat 11 is provided with an inflator for inflating the workpiece 10 to be measured Components (the installation method of the inflatable component can be designed according to the actual design, it can be installed on the frame 1, the workpiece seat 11 alone or on the frame 1 and the workpiece seat 11 at the same time), and the frame 1 is also equipped with a 10 to detect its transparent water tank 12 of air leakage. After the workpiece 10 to be tested is placed in the workpiece seat 11, it is fixed, and the transparent 12 is automatically raised until the workpiece 10 to be tested is completely immersed in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com