Tester for testing fiber axial heat conduction performance and production method thereof

A technology of thermal conductivity and fiber, which is applied in the field of specimen and preparation of fiber axial thermal conductivity test, which can solve the problems of difficulty in testing and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The present invention also provides a method for preparing the above-mentioned test piece for fiber axial thermal conductivity test, comprising the following steps:

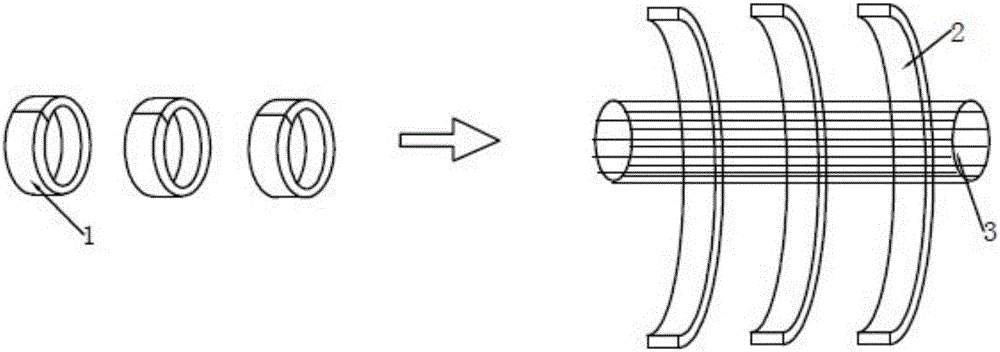

[0055] Provide three grippers, and make the axes of the three grippers the same line;

[0056] Arrange the fibers to be tested and run through the inside of the three-piece holder;

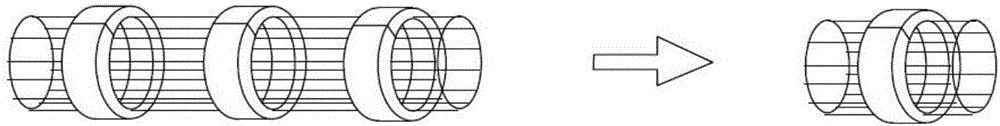

[0057] Stretch the grippers at both ends to the outside of both ends;

[0058] Cut the fibers at both ends of the intermediate holder to obtain a test piece.

[0059] The present invention provides a three-piece holder, and makes the axes of the three-piece holder be the same straight line. In the present invention, the three-piece holders are spaced apart by a certain distance.

[0060] In the present invention, the fibers to be tested are arranged and run through the inside of the three-piece holder. In the present invention, if the holder is an open holder, the present invention preferably loads the fiber to be tested f...

Embodiment 1

[0067] Step 1: Calculation of Fiber Bundle Volume Filling Rate

[0068] In this example, the carbon fiber of model M40J is used, and the fiber body density is 1.81g / cm 3 , the number of fiber bundles in the cross-section is 808 bundles, and the fiber volume filling rate is calculated as 68% through formulas 1.1 to 1.4.

[0069] Step 2: Carbon Fiber Holder Preparation

[0070] The sample holder is a polyvinyl chloride tube with an inner diameter of 12mm, a wall thickness of 2mm, and a length of 1mm, and its side is cut parallel to the axis of the holder.

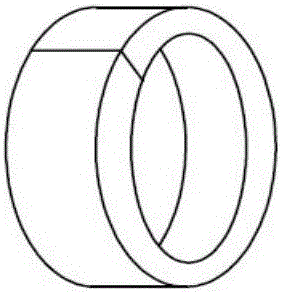

[0071] The schematic diagram of the structure of the clamper described in this embodiment is as follows figure 1 shown by figure 1 It can be seen that the holder is in the shape of a hollow straight cylinder, and the cylinder wall is provided with an opening parallel to the axis of the hollow straight cylinder.

[0072] Step Three: Fiber Loading

[0073] Cut the continuous fiber tow into neat fiber segments with a length...

Embodiment 2

[0081] Step 1: Calculation of Fiber Bundle Volume Filling Rate

[0082] In this example, the glass fiber model EC5.5-1212S110 is used. The diameter of the fiber monofilament is 5.5 μm, the density is 12tex, and the number of fiber bundles in the cross-section is 523 bundles. The fiber volume filling rate is calculated by formulas 1.1-1.4 to be 50%.

[0083] Step 2: Carbon Fiber Holder Preparation

[0084] A high-temperature-resistant polybenzimidazole (PBI) plastic tube is selected as the fiber holder, with a wall thickness of 5 mm, an inner diameter of 15 mm, and a length of 4 mm, and its side is cut parallel to the axis of the holder.

[0085] Step Three: Fiber Loading

[0086] Cut the continuous fiber tow into neat fiber segments with a length of 8 cm, soak the fiber segments in absolute ethanol for 20 minutes, take them out, arrange them neatly, and ensure that the fibers are not twisted, and at the same time avoid fiber bifurcation, fluffing and breakage. Arrange the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com