Detection method of grouting compactness for assembly-type shear wall pipeline

A detection method and shear wall technology, which are applied to measuring devices, processing response signals of detection, and analyzing solids using sonic/ultrasonic/infrasonic waves, etc., can solve the problems of poor detection efficiency and complicated steps, and achieve clear signal response and effect. Significant, simple data collection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

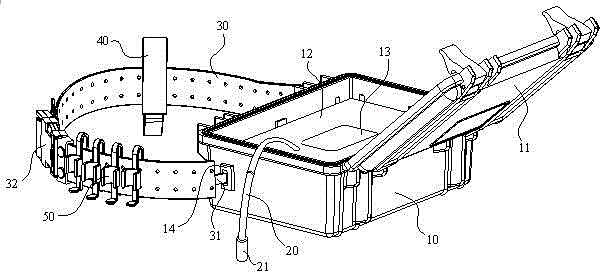

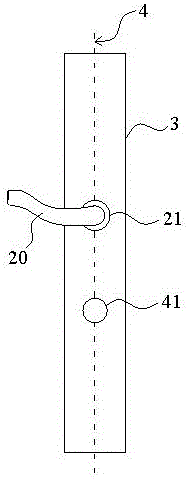

[0032] Such as figure 1 As shown, the present invention provides a method for detecting the compactness of the grouting of the prefabricated shear wall pipeline. The detection method uses a combined detection device for detection. The combined detection device includes a box body 10, and the box There is a host 12 inside the body 10, a cable 20 is connected to the host 12, a sensor 21 is connected to the end of the cable 20, a detachable waist belt 30 is arranged on the outside of the box body 10, and a display can be installed on the host 12. The screen 13 and the box body 10 may be provided with a box cover 11 for covering the box body 10 . When the detection device of this technical solution is in use, the sensor 21 is first placed at the position to be detected in the shear wall grouting pipe, and then the vibration device (usually a steel ball, a vibration hammer or an impact hammer) is used to strike near the sensor 21 The vibration is excited, and the host computer 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com