FCT fixture

A technology of test fixtures and fixtures, which is applied in the direction of measuring devices, measuring electrical variables, measuring device casings, etc., can solve the problems of dismantling and assembling a lot of things, taking up a lot of space, and causing injury to employees, so as to improve test efficiency, occupy a small space, and facilitate The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

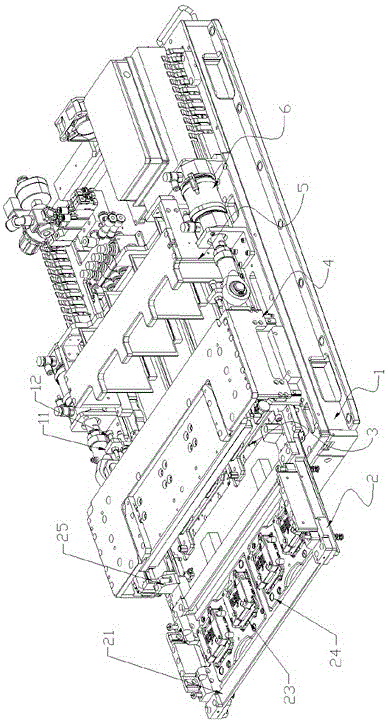

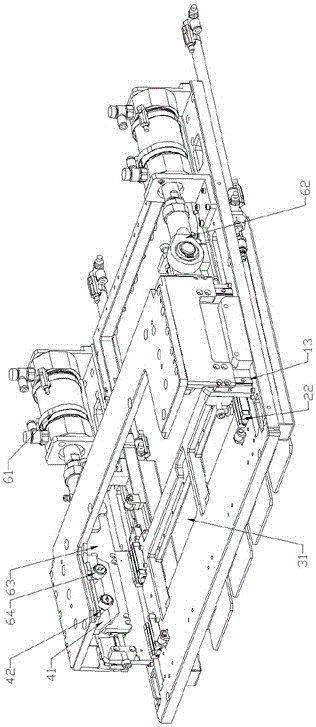

[0025] Such as Figure 1 to Figure 3 As shown, this embodiment includes a fixture body 1 and a tray module 2, a needle plate module 3, a platen module 4, a PCB test module 5 and a mechanical transmission module that are sequentially arranged on the fixture body 1 from front to back 6. The tray module 2 is mated with the fixture body 1 and adapted to the product 7. The needle board module 3 is located below the platen module 4 and is connected to the PCB test module. Group 5 is electrically connected, and the mechanical transmission module 6 is electrically connected to an external controller.

[0026] The height of the clamp body 1 is 133.5 mm.

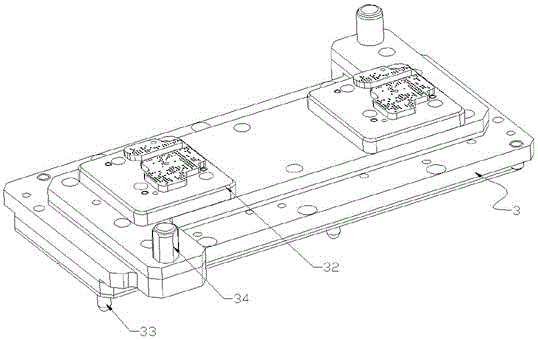

[0027] The tray module 2 includes a carrier plate 21 and horizontal sliders arranged at the left and right ends of the carrier plate 21, and the horizontal slider slides with the horizontal slide rail 22 arranged on the upper end surface of the clamp body 1 In cooperation, the carrier plate 21 is provided with four slots 23 compatib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com