Lens assembly capable of realizing automatic focusing by adopting fixed focus lens

An automatic focusing and fixed focal length technology, applied in the field of optical lenses and security surveillance cameras, can solve the problems of high requirements for driving motors, large chip size, unreliability, etc., to achieve low manufacturing costs, reduced design difficulty and cost, and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

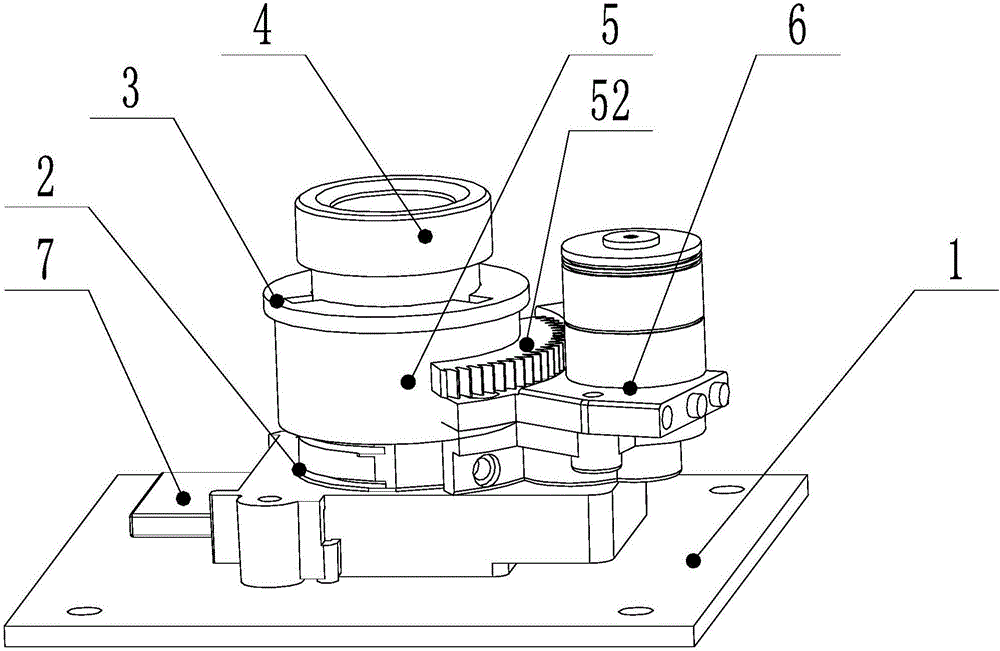

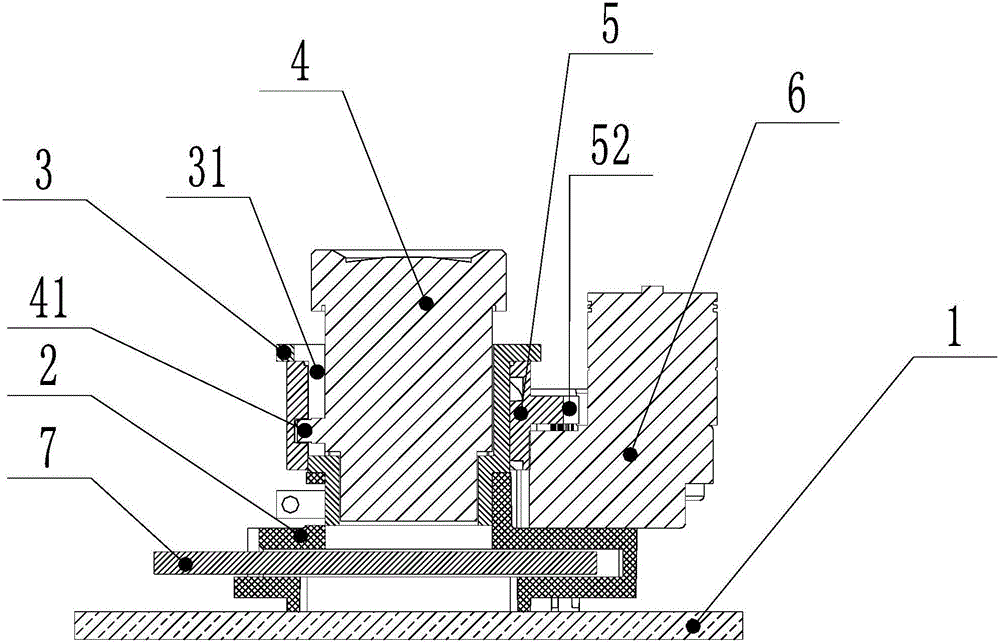

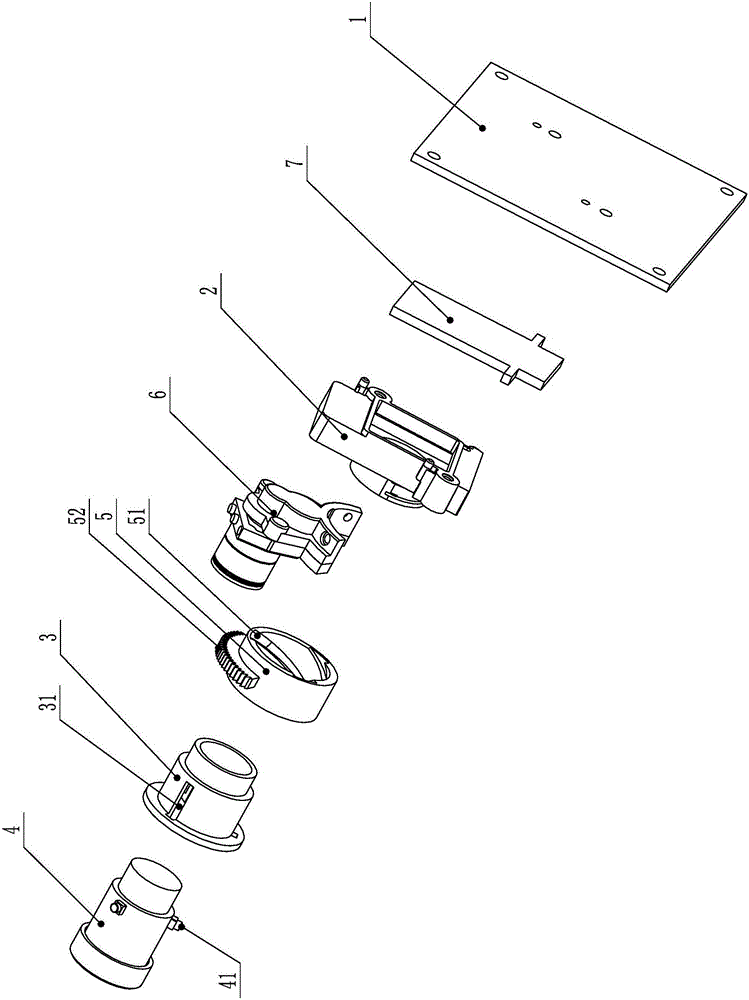

[0028] like Figure 1-3 As shown, a lens assembly that adopts a fixed focal length lens to realize automatic focusing provided by the present invention includes a motherboard chip 1 of the camera, a lens mount 2 fixed on the motherboard chip 1, and a lens mount 2 fixed on the lens mount 2. Lens fixing sleeve 3, a coaxial movable fixed-focus lens set in the lens fixing sleeve 3 and capable of moving axially relative to the lens fixing sleeve 3 4, a coaxial adjustable ring set in the outer periphery of the lens fixing sleeve 3 5 and an automatic focus control motor 6 fixed on the lens mount 2 for driving the adjusting ring 5 to rotate relative to the lens fixing sleeve 3; the outer peripheral wall of the fixed focus lens 4 is provided with guides extending radially outward Nail 41, the inner peripheral wall of the adjustment ring 5 is provided with a guide chute 51 that cooperates with the guide nail so that the fixed focus lens 4 can be axially displaced relative to the lens fi...

Embodiment 2

[0034] like Figure 4-6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the guide chute is a straight slot extending parallel to the axial direction of the inner peripheral wall of the adjustment ring 5, and the through groove is along the axis of the wall of the lens fixing sleeve 3. Cam ramps that spiral forward in direction. When the adjusting ring rotates, the fixed-focus lens produces both axial displacement and rotation relative to the lens fixing sleeve.

Embodiment 3

[0036] like Figure 7-9 As shown, the difference between Embodiment 3 and Embodiment 1 is that the autofocus control motor 6 is fixed on the lens fixing sleeve 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com