48V micro-hybrid braking energy recovery experiment system based on CVT speed ratio control

A technology of braking energy recovery and speed ratio, applied in the direction of measuring electricity, measuring devices, vehicle testing, etc., can solve the problems of reducing design difficulty and cost, reducing volume and cost, etc., to reduce design difficulty and cost, reduce Small size and cost, easy wiring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. This embodiment is only used to explain the present invention and does not limit the protection scope of the present invention.

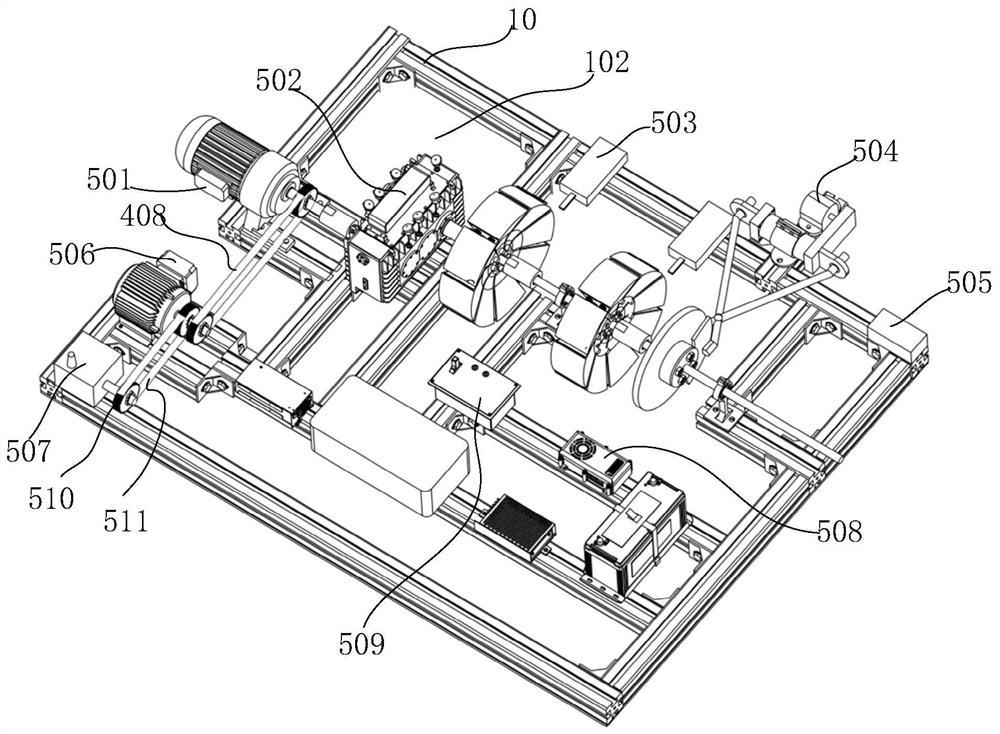

[0043] Such as figure 1 As shown, the 48V micro-mixing system brake energy recovery experimental system based on CVT speed ratio control of the present invention includes a frame base 10, a loading device, a mechanical brake device, an energy recovery device and a control device, wherein the frame base 10 is the entire system Provide support and connect various devices; the loading device is used to simulate the kinetic energy of the car; the mechanical brake device and energy recovery device simulate the mechanical brake and motor brake of the car.

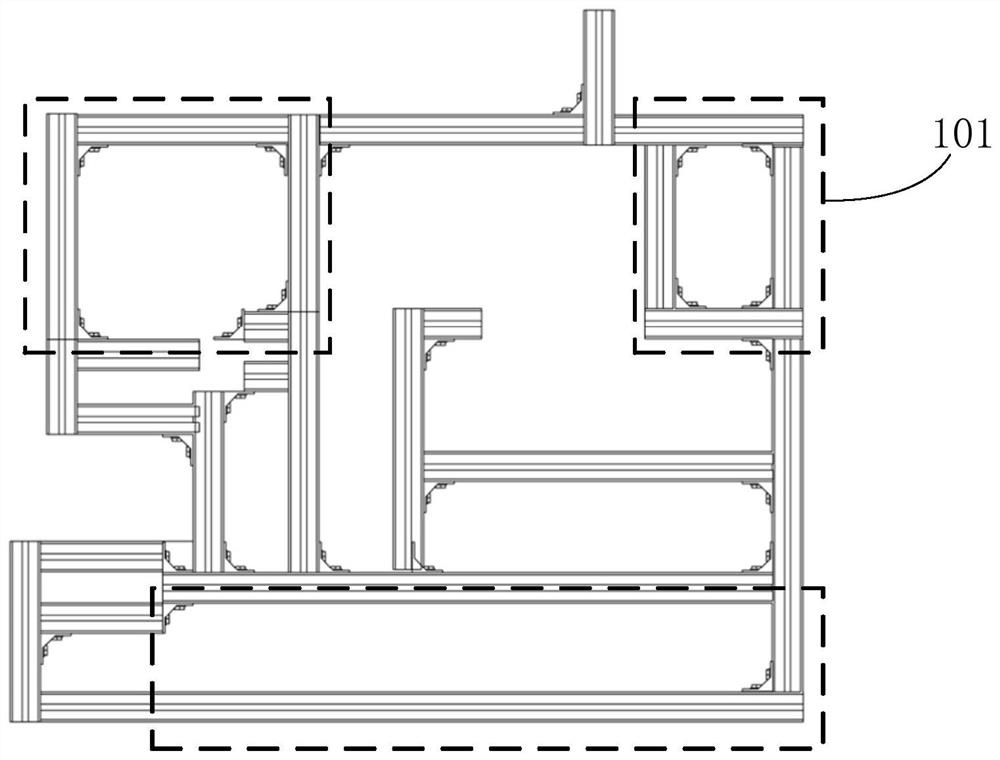

[0044] In this embodiment, the frame base 10 is formed by connecting aluminum alloy profiles of different lengths through angle steel. In particular, the frame base 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com